Preparation method of edible antibacterial film

An antibacterial film and film-forming technology, which is applied in the field of preparation of edible antibacterial film, can solve the problems of poor antibacterial effect, achieve the effects of avoiding irritating odor, improving antibacterial performance, and improving structural compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

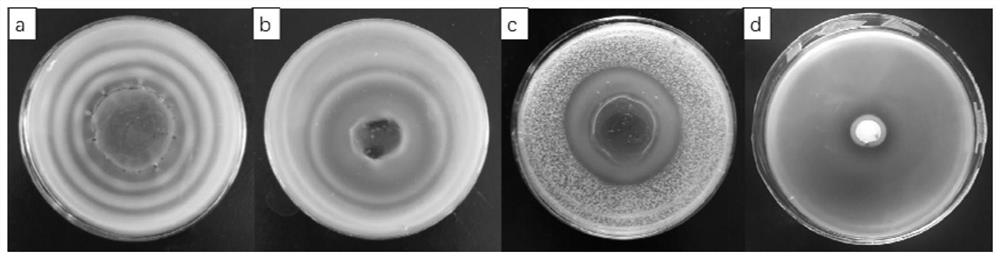

Image

Examples

Embodiment 1

[0025] Take by weighing 0.5g chitosan and be dissolved in 1% (w / v) L-malic acid, make chitosan solution concentration be 1.5% (w / v), add the glycerin that is 15% of chitosan quality, fully Stir to combine well. Take by weighing 0.5g cornstarch and dissolve in water so that the concentration of the starch solution is 3% (w / v), add 15% glycerol that is the starch mass, gelatinize at 80°C for 30min, cool to room temperature and mix with the chitosan solution uniform. Add 0.12g of nano-ZnO, shear and mix at 2000r / min, ultrasonic degassing for 30min, coat the mixed solution on a polytetrafluoroethylene mold, and dry at 60°C for 24h to obtain a membrane material, which is subjected to antibacterial experiment.

Embodiment 2

[0035] This example is basically the same as Example 1, the only difference is that the concentration of L-malic acid is 3% (w / v).

Embodiment 3

[0037] This example is basically the same as Example 1, the only difference is that the concentration of L-malic acid is 5% (w / v).

[0038] Table 2 Composite film inhibition zone size

[0039] Composite Film Formulation Solvent concentration (L-malic acid) Antibacterial zone diameter / mm Example 1 Chitosan / Starch / Nano ZnO 1% 46 Example 2 Chitosan / Starch / Nano ZnO 3% 44 Example 3 Chitosan / Starch / Nano ZnO 5% 43

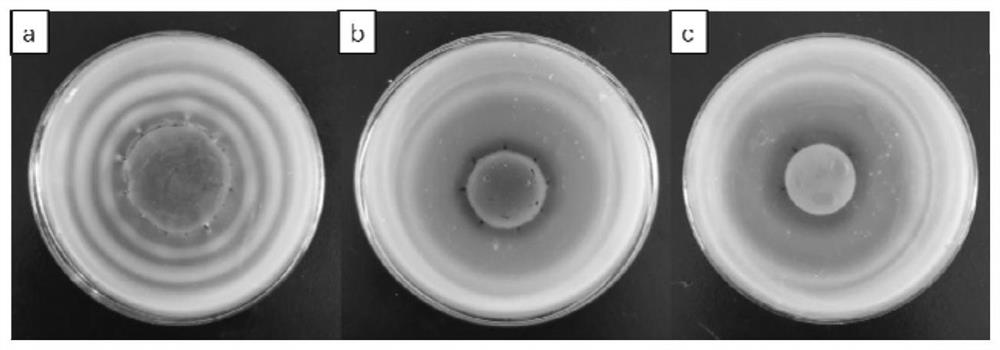

[0040] figure 2 It is the antibacterial effect figure of composite film: a is the antibacterial effect figure of the antibacterial film that embodiment 1 makes to Staphylococcus aureus; b is the antibacterial effect figure of the antibacterial film that embodiment 2 makes to Staphylococcus aureus; c is the implementation The antibacterial effect figure of the antibacterial film that example 3 makes to Staphylococcus aureus.

[0041] Table 2 and figure 2 Shown, the antibacterial film inhibition zone diameter that embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com