Vehicular composite concrete mixing drum and method for manufacturing same

A composite material and concrete technology, which is applied in the direction of clay preparation equipment, cement mixing equipment, chemical instruments and methods, etc., can solve the problems of short service life, high replacement cost, easy wear, etc., achieve long service life, reduce operating costs, Excellent corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

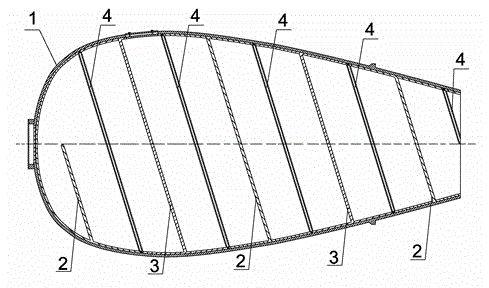

[0023] Such as figure 1 and figure 2 As shown, the vehicle-mounted composite material concrete mixing drum provided by the invention comprises: an outer cylinder wall (1) and an inner cylinder wrapped in the outer cylinder wall (1), and the outer cylinder wall (1) is made of reinforced fiber yarn After being impregnated with curable resin, it is formed by winding and curing on the outer surface of the inner cylinder through a winding process. The inner cylinder is formed by rotating the first helical member (2) through 180 degrees and passing the second helical member (3) through polyurethane The adhesive (4) is glued together, and the structure of the first spiral member (2) and the second spiral member (3) is the same.

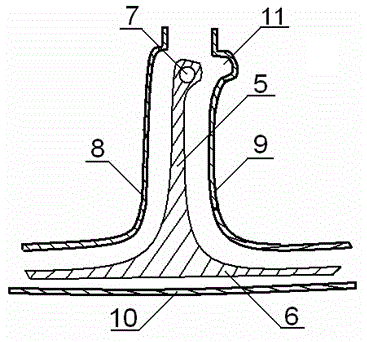

[0024] In the vehicle-mounted composite material concrete mixing drum described above, the first helical member (2) and the second helical member (3) each include a helical blade (5) and a screw connected to the helical blade (5). The spiral inner cylinde...

Embodiment 2

[0028] A preparation method for a vehicle-mounted composite material concrete mixing drum, which specifically includes the following steps:

[0029] a, the preparation of the first helical member (2) and the second helical member (3): as figure 2 As shown, first the second spiral inner mold (9) is installed and fixed on the support; the spiral reinforced round rod (7) is installed and fixed on the end of the second spiral inner mold (9) with a polyurethane elastomer spacer In the groove (11); the first helical inner mold (8) and the helical outer mold (10) are installed on the second helical inner mold (9) successively, so that the first helical inner mold (8), A spiral sealed cavity is formed between the second spiral inner mold (9) and the spiral outer mold (10); inject polyurethane resin and its auxiliary agent into the cavity; after the resin is solidified, remove the spiral The outer mold (10), the first helical inner mold (8) and the second helical inner mold (9) form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com