Thermal conductive graphene thin film and preparation method thereof

A technology of conductive graphite and graphene, which is applied in chemical instruments and methods, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve the problem of poor mechanical properties of graphene films, difficulties in preparing graphene films, and mechanical properties of graphene films. Performance and thermal and electrical conductivity can not meet the rapid development of electronic technology and other issues, to achieve the effect of improving mechanical properties and thermal and electrical conductivity, eliminating defects, and improving structural compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

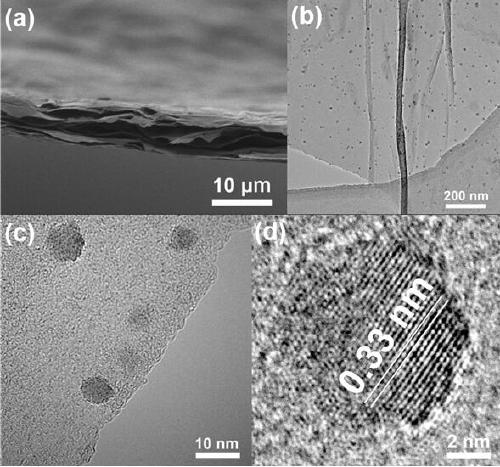

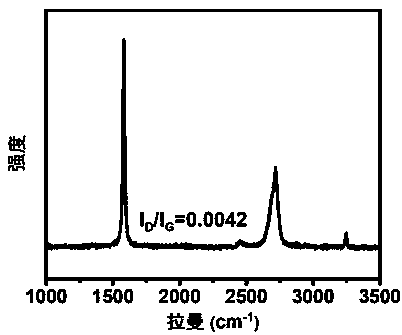

Image

Examples

Embodiment 1

[0035] Step 1), take 3g of graphite flakes with an average size of 200 μm, add 3g of chromium trioxide, 30ml of hydrochloric acid, wash at room temperature for 0.5h, add 15ml of hydrogen peroxide to react for 0.5h and vacuum dry for 1h to obtain expanded graphite;

[0036] Step 2) Take 1g of expanded graphite, add 50ml of concentrated sulfuric acid and 50ml of phosphoric acid, stir at a low temperature of 0°C for 5min, then add 1g of potassium permanganate, and react at 0°C for 1h;

[0037] Step 3), add 100ml of ice water, and add 5ml of hydrogen peroxide to react for 5min, add 5ml of hydrochloric acid to react for 1h, centrifuge to remove the acid solution, wash with deionized water until the pH is 6-7, and stir magnetically at room temperature for 0.5h to obtain Graphene oxide aqueous solution with an average size of 120-150 μm.

Embodiment 2

[0039] Step 1), take 3g of flake graphite with an average size of 500 μm, add 30g of chromium trioxide, 200ml of hydrochloric acid, wash it after reacting at room temperature for 1h, add 500ml of hydrogen peroxide to react for 6h, and vacuum dry for 12h to obtain expanded graphite;

[0040] Step 2) Take 1g of expanded graphite, add 120ml of concentrated sulfuric acid and 60ml of phosphoric acid, stir at a low temperature of 10°C for 120min, then add 15g of potassium permanganate, and react at 50°C for 12h;

[0041] Step 3), add 600ml of ice water, and add 200ml of hydrogen peroxide to react for 120min, add 100ml of hydrochloric acid to react for 24h, centrifuge to remove the acid solution, wash with deionized water until the pH is 6-7, and stir magnetically at room temperature for 24h to obtain the average Graphene oxide aqueous solution with a size of 120-150 μm.

Embodiment 3

[0043] Step 1), take 3g flake graphite with an average size of 1000 μm, add chromium trioxide 90g, hydrochloric acid 300ml, wash clean after reacting at room temperature for 5h, add hydrogen peroxide 900ml to react for 96h, and vacuum dry for 96h to obtain expanded graphite;

[0044]Step 2) Take 1g of expanded graphite, add 500ml of concentrated sulfuric acid and 500ml of phosphoric acid, stir at a low temperature of 5°C for 480min, then add 90g of potassium permanganate, and react at 100°C for 96h;

[0045] Step 3), add 2500ml of ice water, and add 500ml of hydrogen peroxide to react for 480min, add 200ml of hydrochloric acid to react for 96h, centrifuge to remove the acid solution, wash with deionized water until the pH is 6-7, and stir magnetically at room temperature for 48h to obtain the average Graphene oxide aqueous solution with a size of 120-150 μm.

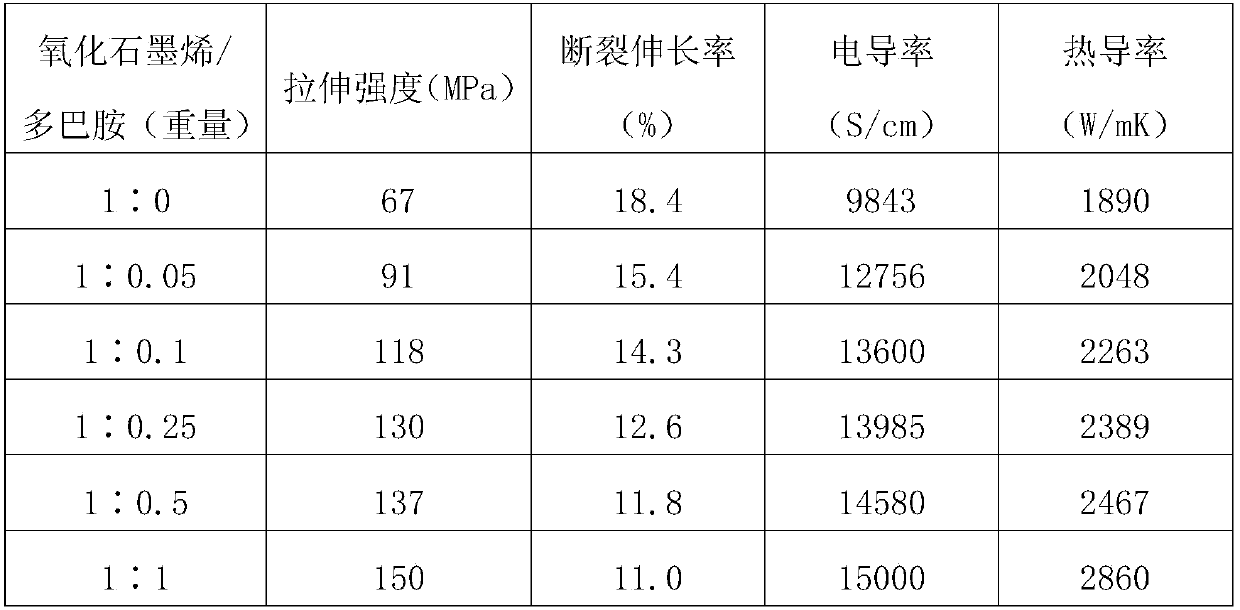

[0046] The embodiment that prepares thermally conductive graphene film has:

[0047] Example 1

[0048] Step 1, prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com