Modified cement and application thereof

A cement and modification technology, which is applied in the field of building material preparation, can solve the problems of reducing the durability of concrete structures, and achieve the effects of improving electrochemical corrosion resistance, improving later strength, and improving impermeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

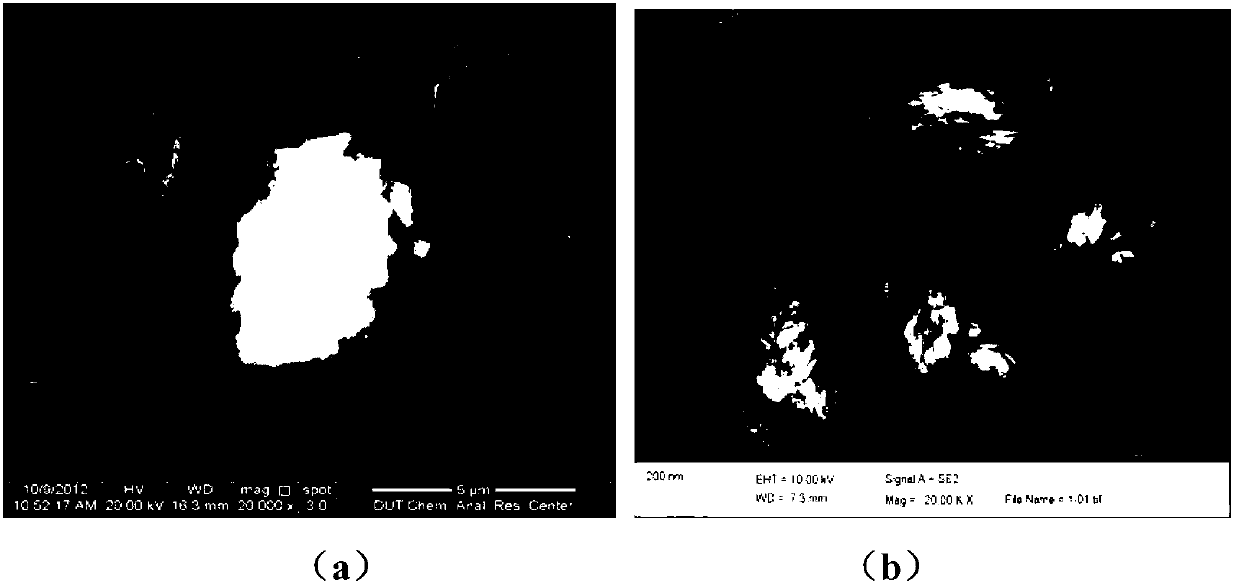

[0032] (1) The slag micropowder used in the present invention is the S95 grade slag micropowder produced by Dalian Jinqiao Superfine Powder Co., Ltd., and its particle size is 6.5~8.4 μm, figure 1 (a) The microscopic morphology of slag powder is given; the nano-clay is nano-kaolin produced by Hebei Xingtai Hualiang Rubber and Plastic Material Co., Ltd., with an average particle diameter of 300-500nm and an average sheet thickness of 20-50nm. figure 1 (b) The microstructure of nanoclay is given; the water reducer used is β-naphthalene sulfonate formaldehyde polymer high-efficiency water reducer produced by Dalian Bangda Building Materials Co., Ltd.; the cement is PO· 42.5R ordinary Portland cement; the sand is sand from a large river, and the gravel is crushed stone of 1-3mm.

[0033] (2) Test concrete specimen mix ratio

[0034] In this test, the amount of slag powder is selected as 50% of the total mass of the cementitious material, the nano-clay accounts for 1% of the tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com