Production method of low pressure formed foil

A manufacturing method and technology of forming foil, applied in electrolytic capacitors, electrical components, circuits, etc., can solve problems such as weak bonding, environmental pollution, and increased waste discharge, achieve good passivation treatment effects, save raw material resources, and excellent The effect of hydration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

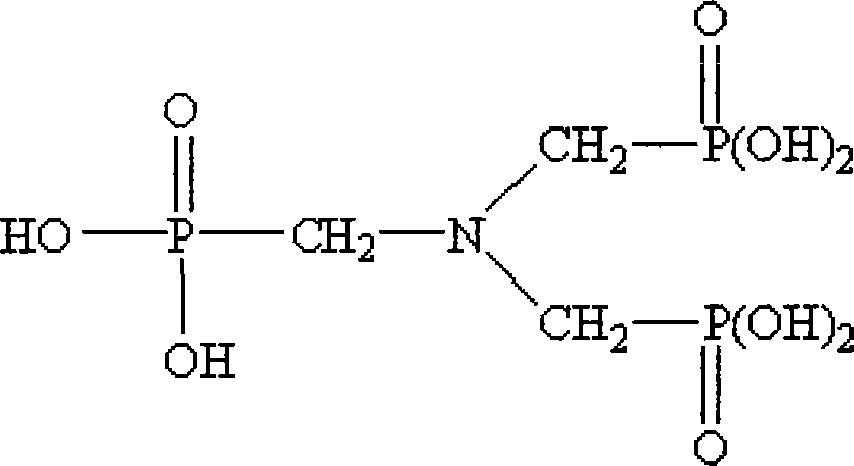

Method used

Image

Examples

Embodiment 1

[0024] According to the method of the present invention, making the foil with the highest conversion voltage of 20V, the specific method is as follows:

[0025] 1) The low-pressure corrosion foil is chemically treated in a 0.4mol / L ammonium adipate solution at 70°C, and the maximum applied voltage is 20V;

[0026] 2) Soak the foil in 0.25mol / L phosphoric acid solution at 60°C for 2 minutes, and then wash it with pure water;

[0027] 3) Perform the first re-formation treatment on the foil in the bath solution and temperature of 1), and the maximum applied voltage is 20V;

[0028] 4) Clean the formed foil and heat-treat it in an air atmosphere at a temperature of 500°C for 2 minutes;

[0029] 5) Carry out the second re-formation of the foil, the solution used is 0.4mol / L ammonium adipate + 0.02mol / L ammonium dihydrogen phosphate at 70°C, and the maximum applied voltage is 20V;

[0030] 6) After the foil is energized, the temperature of the bath is 80°C, and the bath contains 1...

Embodiment 2

[0036] According to the method of the present invention, the foil with the highest conversion voltage of 100V is made, and the specific method is as follows:

[0037]1) The low-pressure corrosion foil is subjected to chemical formation treatment in a 0.6mol / L ammonium adipate solution at 85°C, that is, the highest chemical formation voltage is 100V;

[0038] 2) Soak the formed foil in 0.38mol / L phosphoric acid solution at 70°C for 2 minutes, and then wash it with pure water;

[0039] 3) Perform the first re-formation treatment on the foil in the bath solution and temperature of 1), and the maximum applied voltage is 100V;

[0040] 4) Clean the formed foil and perform heat treatment in the air atmosphere at a temperature of 520°C for 2.5 minutes;

[0041] 5) Carry out the second re-formation of the foil, the solution used is 0.4mol / L ammonium adipate + 0.4mol / L ammonium dihydrogen phosphate at 75°C, and the maximum applied voltage is 100V;

[0042] 6) After the foil is energi...

Embodiment 3

[0049] According to the method of the present invention, the foil with the highest conversion voltage of 50V is made, and the specific method is as follows:

[0050] 1) The low-pressure corrosion foil is subjected to chemical conversion treatment in a 0.9mol / L ammonium adipate solution at 80°C, with a maximum chemical conversion voltage of 50V;

[0051] 2) Soak the foil in a 0.28mol / L phosphoric acid solution at 60°C for 2.5 minutes, and then wash it with pure water;

[0052] 3) Perform the first re-formation treatment on the foil in the bath solution and temperature of 1), and the maximum applied voltage is 50V;

[0053] 4) Clean the formed foil and perform heat treatment in the air atmosphere at a temperature of 490°C for 3 minutes;

[0054] 5) Carry out the second re-formation of the foil, the solution used is 0.4mol / L ammonium adipate + 0.2mol / L ammonium dihydrogen phosphate at 60°C, and the maximum applied voltage is 50V;

[0055] 6) The foil is treated after power-on, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com