Catalyst for synthesis of natural through methanation of coal and preparation method thereof

A coal-based methane, chemical synthesis technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of limited practical application and small specific surface area, and achieve high mechanical strength and high specific area Excellent surface area and hydration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

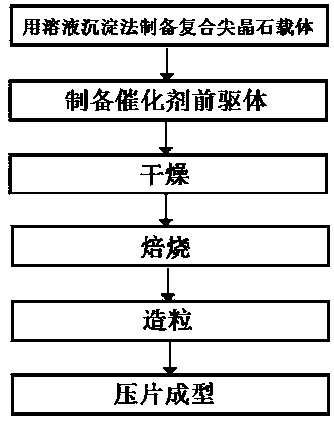

[0048] A preparation method for a catalyst for coal-based methanation to synthesize natural gas, comprising the following steps (see figure 1 ):

[0049] (1) Preparation of composite spinel support by solution precipitation method

[0050] ① 20.51g magnesium nitrate (Mg(NO 3 ) 2 ﹒ 6H 2 O), 5.94g zinc nitrate (Zn(NO 3 ) 2﹒ 6H 2 O), 75.00g aluminum nitrate (Al(NO 3 ) 3﹒ 9H 2 O) and 0.75g of polyvinyl alcohol (PVA) were dissolved in 500ml of deionized water to prepare a mixed solution, stirred at 70°C for 1 hour to fully dissolve, and salt solution A was obtained.

[0051] ② Add 15.90g of sodium carbonate (Na 2 CO 3 ) and 20.00g of sodium hydroxide (NaOH) were dissolved in 500ml of deionized water and stirred for 1 hour to fully dissolve it to form alkaline solution B.

[0052] ③ Add the salt solution A and the alkali solution B dropwise into a beaker simultaneously for precipitation: control the precipitation temperature to 60°C, and the pH value to 10. After the pr...

Embodiment 2

[0065] A preparation method for a catalyst for coal-based methanation to synthesize natural gas, comprising the following steps (see figure 1 ):

[0066] (1) Preparation of composite spinel support by solution precipitation method

[0067] ① 12.82g magnesium nitrate (Mg(NO 3 ) 2 ﹒ 6H 2 O), 14.85g zinc nitrate (Zn(NO 3 ) 2﹒ 6H 2 O), 75.00g aluminum nitrate (Al(NO 3 ) 3﹒ 9H 2 O) and 2.44g of activated carbon were dissolved in 500ml of deionized water to prepare a mixed solution, and stirred at 80°C for 1 hour to fully dissolve it to obtain salt solution A.

[0068] ② 31.80g sodium carbonate (Na 2 CO 3 ) was dissolved in 500ml deionized water, and then mixed with 3.3g ammonia water (NH 3 ﹒ h 2 O) h mixed and stirred for 1 hour to make it fully dissolved to form alkaline solution B.

[0069] ③ Add the salt solution A and the alkali solution B dropwise into a beaker simultaneously for precipitation: control the precipitation temperature to 70°C, and the pH value to ...

Embodiment 3

[0082] A preparation method for a catalyst for coal-based methanation to synthesize natural gas, comprising the following steps (see figure 1 ):

[0083] (1) Preparation of composite spinel support by solution precipitation method

[0084] ① 17.95g magnesium nitrate (Mg(NO 3 ) 2 ﹒ 6H 2 O), 8.91g zinc nitrate (Zn(NO 3 ) 2﹒ 6H 2 O), 75.00g aluminum nitrate (Al(NO 3 ) 3﹒ 9H 2 O) and 0.77g of acetylene carbon black were dissolved in 500ml of deionized water to prepare a mixed solution, stirred at 65°C for 1 hour to fully dissolve it, and the salt solution A was obtained.

[0085] ②Add 21.20g of sodium carbonate (Na 2 CO 3 ) and 50.4g of sodium hydroxide (NaOH) were dissolved in 500ml of deionized water and stirred for 1 hour to fully dissolve to form alkaline solution B.

[0086] ③ Add the salt solution A and the alkali solution B dropwise into a beaker for precipitation: control the precipitation temperature to 80°C, and the pH value to 9.5. After the precipitation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com