High-stability polynary composite oxide refractory material for high-activity high-temperature alloy smelting, and application and preparation method thereof

A multi-component composite and refractory technology is applied in the fields of composite oxide refractory materials and their application and preparation, and refractory materials and their application and preparation fields. Achieve the effect of low preparation cost, good thermal shock resistance and good hydration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

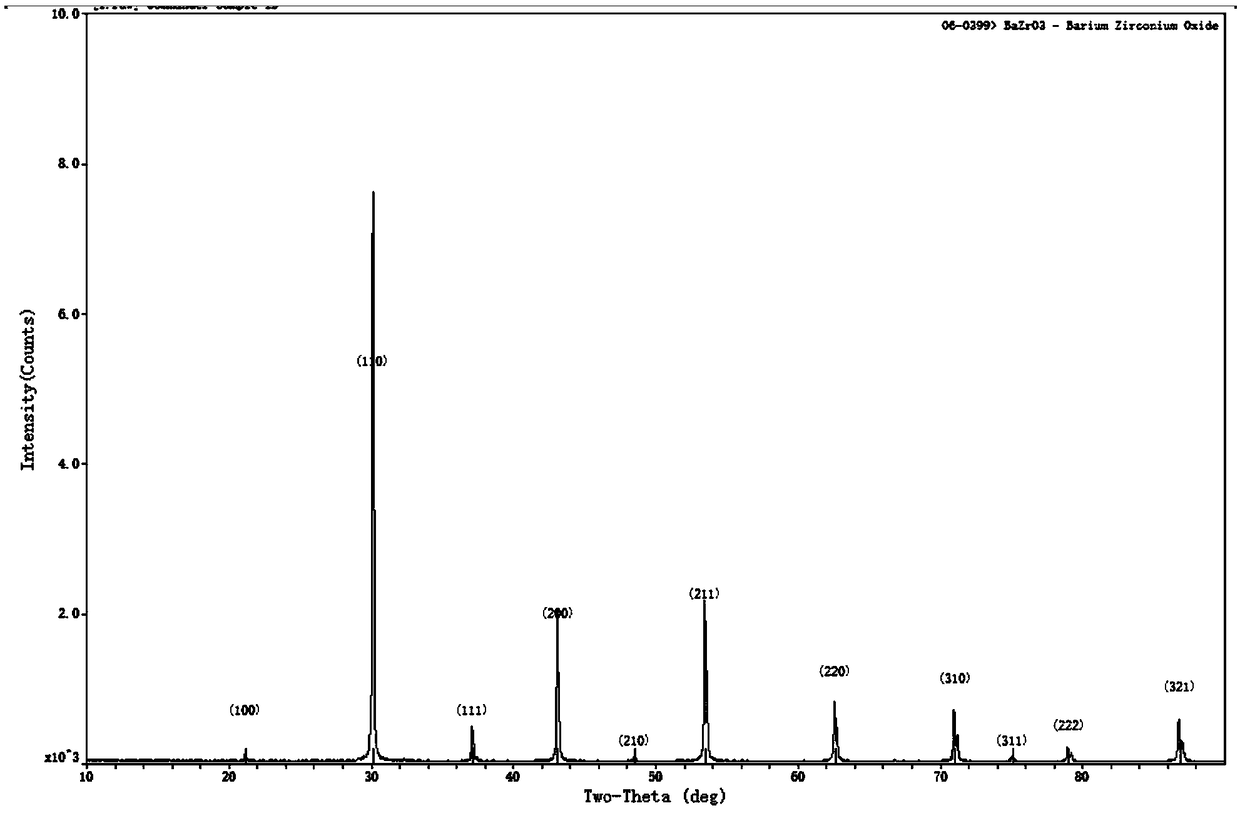

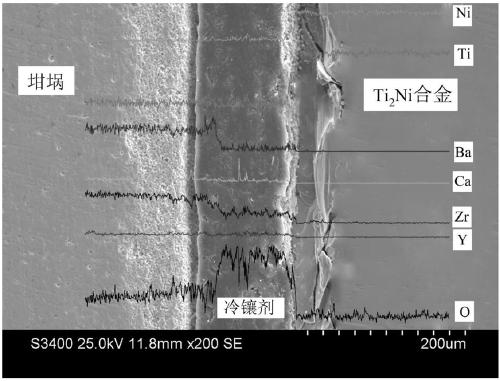

[0042] In this embodiment, a high-stability multi-component composite oxide refractory material for high-activity superalloy smelting, its components include alkaline earth metal element compounds, transition metal element compounds and rare earth element compounds; in this embodiment, alkaline earth metal The element compound main phase component compound and the alkaline earth metal element compound doping phase component compound are different compounds;

[0043] Among them, the alkaline earth metal element compound includes BaCO as the main phase component compound of the alkaline earth metal element compound 3 and CaCO as an alkaline earth metal element compound doped phase component compound 3 ; The transition metal element compound is ZrO 2 ; The rare earth element compound is Y 2 o 3 ; using pure BaCO 3 ,CaCO 3 ,ZrO 2 and Y 2 o 3 , the ratio of each component calculated according to the mole percentage of the components of the multi-element composite oxide refr...

Embodiment 2

[0059] This embodiment is basically the same as Embodiment 1, especially in that:

[0060] In this embodiment, a method for preparing a high-stability multi-component composite oxide refractory material for smelting a high-activity superalloy comprises the following steps:

[0061] a. Take alkaline earth metal element compounds, transition metal element compounds and rare earth element compounds as raw materials according to the composition ratio, wherein the alkaline earth metal element compounds include BaO as the main phase component compound of the alkaline earth metal element compound and BaO as the alkaline earth metal element compound CaO for doped phase component compounds; TiO for transition metal element compounds 2 ; The rare earth element compound is Yb 2 o 3 ; Using pure BaO, CaO, TiO 2 and Yb 2 o 3 , the raw material ratio of each component calculated according to the mole percentage of the components of the multi-element composite oxide refractory is as fol...

Embodiment 3

[0067] This embodiment is basically the same as the previous embodiment, and the special features are:

[0068] In this embodiment, a method for preparing a high-stability multi-component composite oxide refractory material for smelting a high-activity superalloy comprises the following steps:

[0069] a. Take alkaline earth metal element compounds, transition metal element compounds and rare earth element compounds as raw materials according to the composition ratio, wherein the alkaline earth metal element compounds include Ba(OH) as the main phase component compound of alkaline earth metal element compounds 2 and Ca(OH) as an alkaline earth metal element compound doping phase component compound 2 ; The transition metal element compound is TiO 2 ; The rare earth element compound is CeO 2 ; Using pure Ba(OH) 2 , Ca(OH) 2 、TiO 2 and CeO 2 , the raw material ratio of each component calculated according to the mole percentage of the components of the multi-element composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com