Method for preparing water proof aluminum electric pole foil

An aluminum electrode foil, hydration-resistant technology, applied in circuits, capacitors, electrolytic coatings, etc., can solve the problems of excellent anti-hydration treatment effect of aluminum anodic oxide film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

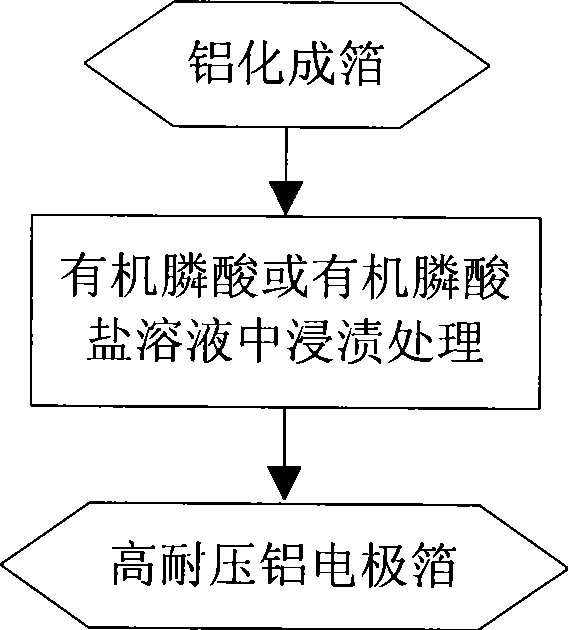

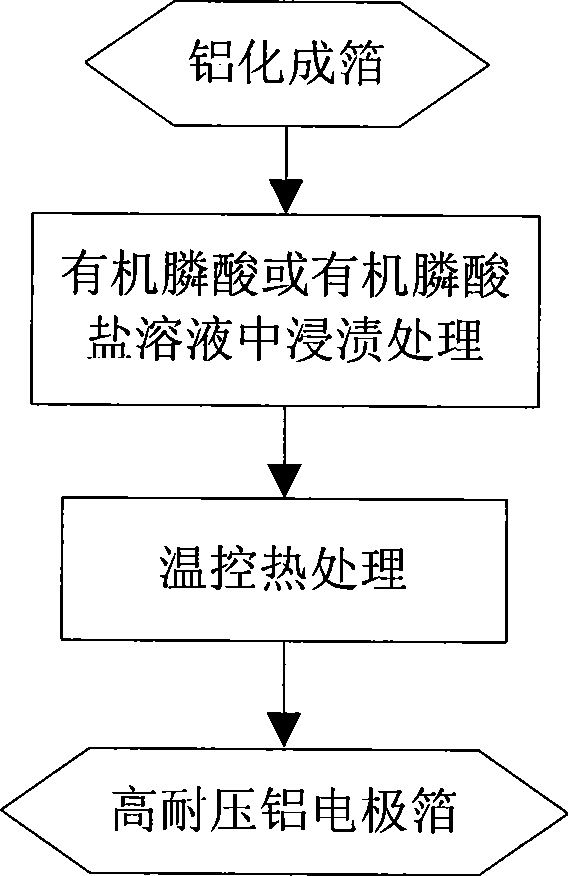

Method used

Image

Examples

Embodiment 1

[0025] After the aluminum corroded foil is subjected to conventional anodic oxidation (formation), the formed foil is immersed in a solution of diethylenetriaminepentamethylenephosphonic acid for hydration resistance treatment. The concentration of the solution of diethylenetriaminepentamethylenephosphonic acid is 0.002mol / L, adjust the pH of the solution to 6.0, control the temperature of the solution to 80° C., and immerse the formed foil in the above-mentioned diethylenetriaminepentamethylenephosphonic acid solution for 4 minutes.

[0026] Through the temperature-controlled heat treatment of the ground temperature section and the high temperature section, the temperature of the low temperature section is controlled at 80°C, and the treatment time is 8 minutes; the temperature of the high temperature section is controlled at 450°C, and the treatment time is 6 minutes. The reaction between the aluminum oxide film and the diethylenetriaminepentamethylene phosphonic acid is ful...

Embodiment 2

[0031] Sodium ethylenediamine tetramethylene phosphonate solution is soaked into hydration resistance treatment, the concentration of sodium ethylenediamine tetramethylene phosphonate solution is 0.01mol / L, the pH value of the solution is adjusted to 6.5, and the pH value of the solution is controlled. The temperature is 50°C, and the immersion time of the chemically formed foil in the above-mentioned sodium ethylenediamine tetramethylene phosphonate solution is 8 minutes.

[0032] In the temperature-controlled heat treatment process, the temperature of the low-temperature section is controlled at 120°C, and the treatment time is 6 minutes; the temperature of the heat treatment at the high-temperature section is controlled at 500°C, and the treatment time is 3 minutes.

[0033] Using the above process steps, the hydration-resistant treatment of the formed foil for domestic low-voltage aluminum electrolytic capacitors was carried out, and the boosting time T of the oxide film af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com