Patents

Literature

30results about How to "Low thermal conductivity at high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Riser heating and insulating agent

InactiveCN101798233AHas the double effect of heat preservationWith feverFoundry mouldsFoundry coresCarbon graphiteSteel casting

The invention discloses a riser heating and insulating agent, which comprises the following components in percentage by weight: 5 to 35 percent of Al, 10 to 25 percent of AlN, 3 to 20 percent of low-carbon graphite, 5 to 25 percent of magnesia-alumina spinel, 5 to 15 percent of quartz, 10 to 30 percent of ferric oxide powder, 5 to 20 percent of corundum, 5 to 10 percent of organosilicon phlogopite, and 1 to 10 percent of MgO; and the riser heating and insulating agent is prepared by the following processes: crushing, pulverizing, mixing, pelletizing, drying, and the like. The riser heating and insulating agent has double effects of heating and insulating, and has good insulating effect. Because the riser heating and insulating agent has a granular appearance, dust and smoke are not generated in the using process, and the environment is not polluted. Due to the adoption of the low-carbon graphite, castings do not have carburizing phenomenon, and the molten steel is not polluted. The riser heating and insulating agent is particularly applied to open risers of low carbon steel large-scale steel castings and stainless steel castings with the weight of over 80 tons.

Owner:HENAN UNIV OF SCI & TECH

Preparation method of composite ceramic coating layer

A method for preparing an aluminum alloy element surface coating comprises the following steps of sequentially pre-treating the aluminum alloy element surface, preparing aluminum alloy element surface arcing-blocking coating, preparing aluminum alloy surface insulation composite ceramic coating and performing post-treatment; the preparation of aluminum alloy element surface arcing-blocking coating is to perform coating in a deionized water electrolyte system composed of NaOH, Na2SiO3, (NaPO3)6 and K2ZrF6; the system for the preparation of aluminum alloy element surface coating comprises a stainless steel solution tank (7), tooling (4), an aluminum alloy element (5), a stirrer (2), a thermometer (6), a water-circulating cooling device (1) and power supply equipment (8). The aluminum alloy member surface coating obtained from the method and the system of the invention has the advantages of high toughness and strong binding capacity with the surface of the aluminum alloy element, long service life and excellent heat insulation performance.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Method for preparing aluminum alloy element surface coating and system thereof

ActiveCN102634832APlay a toughening roleImprove high temperature performanceAnodisationComposite ceramicPre treatment

A method for preparing an aluminum alloy element surface coating comprises the following steps of sequentially pre-treating the aluminum alloy element surface, preparing aluminum alloy element surface arcing-blocking coating, preparing aluminum alloy surface insulation composite ceramic coating and performing post-treatment; the preparation of aluminum alloy element surface arcing-blocking coating is to perform coating in a deionized water electrolyte system composed of NaOH, Na2SiO3, (NaPO3)6 and K2ZrF6; the system for the preparation of aluminum alloy element surface coating comprises a stainless steel solution tank (7), tooling (4), an aluminum alloy element (5), a stirrer (2), a thermometer (6), a water-circulating cooling device (1) and power supply equipment (8). The aluminum alloy member surface coating obtained from the method and the system of the invention has the advantages of high toughness and strong binding capacity with the surface of the aluminum alloy element, long service life and excellent heat insulation performance.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

High-infrared reflectivity high-aluminum light fire-resistant thermal insulating material and preparation method thereof

InactiveCN104944987AWide variety of sourcesReduce manufacturing costPhysical chemistryThermal treatment

The invention relates to a high-infrared reflectivity high-aluminum light fire-resistant thermal insulating material and a preparation method thereof. According to the technical scheme of the High-infrared reflectivity high-aluminum light fire-resistant thermal insulating material and the preparation method thereof, 20-40 wt% of potassic raw material, 50-70wt% of titaniferous raw material and 5-10 wt% of binding agents are uniformly mixed, grinding is conducted after molding and thermal treatment are conducted, and A material with particle size ranging from 0.088-1 mm and B material with particle size smaller than 0.088 mm are obtained. 20-40 wt% of alumina particles, 10-25 wt% of alumina fine powders, 5-15 wt% of A material, 5-15 wt% of B material, 5-15 wt% of aluminiferous raw material and 2-10 wt% of potassic raw material are used as mixture, water containing 2-8 wt% of the micture are added, a green body is made by stirring, drying is conducted, cooling is conducted after the thermal treatment is conducted, the green body is soaked with water, then drying is conducted, and the high-infrared reflectivity high-aluminum light fire-resistant thermal insulating material is obtained. The high-infrared reflectivity high-aluminum light fire-resistant thermal insulating material has the advantages that the volume density is low, the compression strength is high, and the high-temperature heat conductivity coefficient is low. The high-infrared reflectivity high-aluminum light fire-resistant thermal insulating material can also be applied to the heat insulation field within 1300 DEG C for a long time.

Owner:苏安能建筑新材料(苏州)有限公司

High-temperature-resistance and heat-insulation coating and production method thereof

InactiveCN102030540AStable Temperature Coefficient CharacteristicsSmall molding shrinkageAlcoholRefractory

The invention relates to the field of high temperature resistance and heat insulation, in particular to a high-temperature-resistance and heat-insulation coating and the production method thereof. The finished product of the coating comprises the following components: 55 to 80 weight parts of inorganic high-temperature refractory adhesive mortar, 5 to 7 weight parts of SiO2 aerogel, 5 to 7 weight parts of hexapotassium titanate whisker, 3 to 5 weight parts of lamellar mica or lamellar metal and 90 to 120 weight parts of acetone or absolute alcohol. The production method comprises the following steps: a) firstly, screening the SiO2 aerogel containing grains with appropriate size, and pouring the appropriate amount of the acetone or the absolute alcohol into the SiO2 aerogel and fully stirring, wherein the contents of the SiO2 aerogel and the acetone or the absolute alcohol are 5 to 7 weight parts of the SiO2 aerogel and 90 to 120 weight parts of the acetone or the absolute alcohol; and b) adding 3 to 5 weight parts of the lamellar mica or 3 to 5 weight parts of the lamellar metal, 55 to 80 weight parts of the inorganic high-temperature refractory adhesive mortar and 5 to 7 weight parts of the hexapotassium titanate whisker to the mixture prepared in the step a), and fully stirring so as to prepare the high-temperature-resistance and heat-insulation coating. The production method is simple and easy to operate. The high-temperature-resistance and heat-insulation material obtained by using the method has the advantages of good heat insulation effect, high strength and wide prospect on the application.

Owner:武汉阜成科技股份有限公司

Method for preparing silicon dioxide/graphene composite aerogel and composite aerogel obtained thereby

ActiveCN110745835ALess investmentIncrease productivityCarbon compoundsSilicon compoundsOrganosolvSilicon oxide

The invention relates to the technical field of aerogel and particularly relates to a method for preparing silicon dioxide / graphene composite aerogel and the composite aerogel obtained thereby. The method comprises the steps of subjecting graphene oxide and amino-containing trialkoxysilane to a reaction so as to obtain alkoxy silanized graphene, ultrasonically dispersing the alkoxy silanized graphene in an organic solvent for hydrolyzing so as to obtain a hydrolyzate A, hydrolyzing a conventional silicon source so as to obtain a hydrolyzate B, uniformly mixing the hydrolyzate A and the hydrolyzate B, carrying out alkaline condensation so as to obtain wet gel, then, carrying out ageing, solvent replacement and surface modification, and then, carrying out drying, thereby obtaining the silicon dioxide / graphene composite aerogel. The silicon dioxide / graphene composite aerogel disclosed by the invention has relatively high mechanical strength, and the coefficient of high-temperature thermalconductivity of silicon dioxide aerogel is lowered due to presence of graphene, so that the silicon dioxide / graphene composite aerogel can be applied to the fields of heat-preserving heat-insulatingmaterials and the like.

Owner:江苏和硅纳米科技有限公司

Calcium silicate fireproofing board and preparation method thereof

The invention provides a calcium silicate fireproofing board and a preparation method thereof. The calcium silicate fireproofing board is prepared from the following raw materials in parts by weight:0.1 to 80 parts of hydrate calcium silicate, 10 to 70 parts of quartz, 0 to 20 parts of cement, 0 to 20 parts of wood pulp fiber and 10 to 70 parts of lime, wherein the ratio of calcium to silicon is0.1 to 5. The preparation method of the calcium silicate fireproofing board comprises the steps of pulping, flow slurry technological molding, steaming curing and drying. The calcium silicate fireproofing board has the advantages that the hydrate calcium silicate is successfully applied to the fireproofing board, the high-temperature thermal conductivity of the calcium silicate fireproofing boardis smaller than 0.2W / (M*K) and the heat shrinkage rate is smaller than 0.3 percent; the problem that a solid waste-based silicon-containing material is difficult to use is solved; the preparation method has the advantages of simplicity, mild conditions, low cost and easiness in industrialized application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-infrared-reflectivity forsterite lightweight refractory and thermal insulation material and preparation method thereof

The invention relates to a high-infrared-reflectivity forsterite lightweight refractory and thermal insulation material and a preparation method thereof. According to the technical scheme, the method comprises the following steps: uniformly mixing a titanium-containing raw material, a magnesium-containing raw material and a binding agent, molding, carrying out heat treatment, and grinding, thus obtaining an A material with a particle size of 0.088-1mm and a B material with a particle size of less than 0.088mm; uniformly mixing a potassium-containing raw material, a titanium-containing raw material and a binding agent, molding, carrying out heat treatment, and grinding, thus obtaining a C material with a particle size of 0.088mm; uniformly mixing the A material, the B material, the C material and a potassium-containing raw material, carrying out heat treatment, and grinding, thus obtaining a D material with a particle size of 0.088-1mm and an E material with a particle size of 0.088mm; and finally, mixing forsterite particles, fine forsterite powder, the A material, the D material, the E material, a magnesium-containing raw material, a silicon-containing raw material and a potassium-containing raw material, molding, drying, carrying out heat treatment, cooling, soaking and drying. The prepared high-infrared-reflectivity forsterite lightweight refractory and thermal insulation material is low in volume density, high in compression strength, and low in high-temperature heat conductivity coefficient.

Owner:WUHAN UNIV OF SCI & TECH

Composition, porous carbon fiber thermal insulation material high-surface-emissivity anti-oxidation coating prepared from composition and preparation method of porous carbon fiber thermal insulation material high-surface-emissivity anti-oxidation coating

ActiveCN109467457AImproving the disadvantages of radiation performance attenuationLower sintering temperatureCeramicwareFiberBoride

The invention relates to a composition, a porous carbon fiber thermal insulation material high-surface-emissivity anti-oxidation coating prepared from the composition and a preparation method of the porous carbon fiber thermal insulation material high-surface-emissivity anti-oxidation coating. The composition comprises the following ingredients: transition metal boride, refractory metal silicide,silicon carbide powder, polycarbosilane and cerium oxide. The preparation method comprises the following steps: preparing pulp; coating the pulp on a porous carbon fiber thermal insulation material; drying the porous carbon fiber thermal insulation material coated with the pulp, then performing thermal treatment on the dried porous carbon fiber thermal insulation material and sintering the porouscarbon fiber thermal insulation material after thermal treatment in sequence, so as to obtain the porous carbon fiber thermal insulation material high-surface-emissivity anti-oxidation coating. The composition is applied to preparation of the coating, so that the sintering temperature can be reduced; the prepared coating has the advantages of being comparatively high in emissivity, comparatively low in high temperature thermal conductivity and good in ultrahigh temperature stability. Therefore, the coating is hopefully applied to a thermal protection system of a hypersonic vehicle.

Owner:BEIJING JIAOTONG UNIV

Nano-Si-based composite thermal insulation paint and preparation method thereof

The invention relates to nano-Si-based composite thermal insulation paint and a preparation method thereof, belongs to the field of thermal insulation paint and aims to solve the problems of powder and slag falling, low high-temperature resistance coefficient, harm to environmental protection and high cost of existing paint. The nano-Si-based composite thermal insulation paint is prepared from thefollowing raw materials in parts by weight: 25-40 parts of waste cellucotton, 10-15 parts of a quick penetrating agent T, 20-30 parts of attapulgite hydrosol, 10-20 parts of silica hydrosol, 80-110 parts of vitrified microbeads, 5-10 parts of floating beads, 10-20 parts of expanded perlite and 380-620 parts of water. The paint comprises the waste cellucotton, a waste material is recycled, and theproblem about environmental protection is solved; ordinary insulation cotton is burnt off easily in case of fires and the protective effect on pipe equipment is lost, while the raw materials of the paint are carbonized and vitrified on surface in high-temperature flames and cannot be burnt off accordingly, and the pipe equipment is protected from losses.

Owner:烟台科立达节能科技有限公司

A kind of preparation method of silica/graphene composite airgel and the composite airgel obtained thereof

ActiveCN110745835BLess investmentIncrease productivityCarbon compoundsSilicon compoundsThermal insulationOrganosolv

The invention relates to the technical field of airgel, in particular to a method for preparing a silica / graphene composite airgel and the obtained composite airgel. Graphene oxide reacts with amino-containing trialkoxysilane to obtain alkoxysilanized graphene, alkoxysilanized graphene is ultrasonically dispersed in an organic solvent for hydrolysis to obtain hydrolyzate A, and conventional silicon sources are hydrolyzed to obtain hydrolyzate B , the hydrolyzate A and the hydrolyzate B are mixed evenly, and the wet gel is obtained after alkaline condensation, and then after aging, solvent replacement and surface modification, the silica / graphene composite airgel is obtained by drying. The silicon dioxide / graphene composite airgel of the present invention has relatively high mechanical strength, and the presence of graphene reduces the high-temperature thermal conductivity of the silicon dioxide airgel, and can be applied in the fields of thermal insulation materials and the like.

Owner:江苏和硅纳米科技有限公司

High-strength lightweight forsterite fireproof material and preparation method therefor

The invention relates to a high-strength lightweight forsterite fireproof material and a preparation method therefor. The scheme is as follows: the preparation method comprises the steps: firstly, uniformly mixing a siliceous raw material, a magnesium salt, a zinciferous raw material, iron powder and boric acid, carrying out forming, carrying out heat treatment in a reducing atmosphere, and carrying out grinding, thereby obtaining a material A; then, mixing the material A, a surfactant, a thickener, an additive and water, and carrying out ball-milling, thereby obtaining slurry; then, uniformly mixing a siliceous raw material, fine magnesia powder, a zinciferous raw material, municipal sludge and a surfactant, carrying out forming, carrying out heat treatment in a reducing atmosphere, carrying out heat treatment in a neutral atmosphere, and carrying out grinding, so as to obtain a material B and a material C; and finally, uniformly mixing magnesia granules, fine magnesia powder, a siliceous raw material, the material B, the material C, a zinciferous raw material and the slurry, carrying out forming, and carrying out heat treatment, thereby preparing the high-strength lightweight forsterite fireproof material. According to the high-strength lightweight forsterite fireproof material and the preparation method therefor, the source of the raw materials is wide, and the production cost is low; and the prepared product is excellent in high-temperature resistance, high in strength and small in high-temperature coefficient of thermal conductivity and can be used in a long term in high-temperature environments in contact with reducing atmosphere, alkaline dust and the like.

Owner:WUHAN UNIV OF SCI & TECH

High-wear-resistance refrigeration device and reinforcing process thereof

InactiveCN108007036AImprove atomic activityHigh hardnessDomestic refrigeratorsAnti-corrosive paintsWear resistantEngineering

The invention discloses a high-wear-resistance refrigeration device and a reinforcing process thereof. The high-wear-resistance refrigeration device comprises a box body, a door body, a drying filterand a heater; and the door body is movably connected to the box body, a refrigeration chamber is arranged in the box body, the drying filter is arranged on the box body, and the heater is used for heating the drying filter. According to the high-wear-resistance refrigeration device, the structure is simple and compact, the wear-resistant effect is good, the reinforcing process is simple and easy to conduct, the reinforced refrigeration device has higher wear resistance, and the service life of the refrigeration device is prolonged.

Owner:博维恩冷冻科技(苏州)有限公司

High-temperature combined type flange

InactiveCN106752476AImprove high temperature performanceImprove insulation performanceFireproof paintsPolycarbonate coatingsAcrylic resinPolyamide

The invention discloses a high-temperature combined type flange. A protective layer is coated on the surface of the flange and comprises the following components in parts by mass: 10-15 parts of zircon powder, 15-18 parts of diatomite, 20-25 parts of isopropanol, 20-40 parts of polyvinyl acetate emulsion, 30-40 parts of acrylic resin, 10-15 parts of polypropylene carbonate glycol, 10-15 parts of 1,4-butanediol, 8-10 parts of ammonium polyphosphate, 1-3 parts of formaldehyde, 7-15 parts of triphenyl phosphate, 14-20 parts of a modified polyamide curing agent, and 10-15 parts of a silane coupling agent. The flange has relatively high temperature resistance and long service life.

Owner:苏州富艾姆工业设备有限公司

Composition, high-emissivity anti-oxidation coating on the surface of porous carbon fiber heat insulating material prepared by using the composition and preparation method thereof

ActiveCN109467457BImproving the disadvantages of radiation performance attenuationLower sintering temperatureCeramicwareFiberBoride

The invention relates to a composition, a porous carbon fiber thermal insulation material high-surface-emissivity anti-oxidation coating prepared from the composition and a preparation method of the porous carbon fiber thermal insulation material high-surface-emissivity anti-oxidation coating. The composition comprises the following ingredients: transition metal boride, refractory metal silicide,silicon carbide powder, polycarbosilane and cerium oxide. The preparation method comprises the following steps: preparing pulp; coating the pulp on a porous carbon fiber thermal insulation material; drying the porous carbon fiber thermal insulation material coated with the pulp, then performing thermal treatment on the dried porous carbon fiber thermal insulation material and sintering the porouscarbon fiber thermal insulation material after thermal treatment in sequence, so as to obtain the porous carbon fiber thermal insulation material high-surface-emissivity anti-oxidation coating. The composition is applied to preparation of the coating, so that the sintering temperature can be reduced; the prepared coating has the advantages of being comparatively high in emissivity, comparatively low in high temperature thermal conductivity and good in ultrahigh temperature stability. Therefore, the coating is hopefully applied to a thermal protection system of a hypersonic vehicle.

Owner:BEIJING JIAOTONG UNIV

High temperature resistance multilayer heat insulating composite material and manufacturing method thereof

InactiveCN101625065BPhysical state stacking pore volumeLow thermal conductivity at high temperatureThermal insulationPipe protection by thermal insulationRefractoryWhiskers

The invention relates to the field of high temperature resistance and heat insulation, in particular to high temperature resistance multilayer heat insulating composite material and a manufacturing method thereof. The finished product comprises the following components according to parts by weight: 1 to 3 parts of quartz fibre meshes, 7 to 12 parts of ceramic high-temperature continuous fibre cloth, 3 to 7 parts of ceramic fibre paper, 55 to 80 parts of inorganic high- temperature refractory mortar, 5 to 7 parts of SiO2 aerogel, 5 to 7 pars of potassium titanate whiskers and 3 to 5 parts of flaky mica or flaky metal. The density of the high temperature resistance multilayer heat insulating composite material finished product prepared through the manufacturing method is very low, and the adhesive effect is good. The method has the advantages that the method is simple and easy to be operated, the heat insulation effect of the product is good, the strength can meet the operating requirement, and the method has wide application prospect.

Owner:武汉阜成科技股份有限公司

High-infrared reflectivity high-aluminum light-weight refractory insulation material and preparation method thereof

The invention relates to a high-infrared reflectivity high-aluminum light fire-resistant thermal insulating material and a preparation method thereof. According to the technical scheme of the High-infrared reflectivity high-aluminum light fire-resistant thermal insulating material and the preparation method thereof, 20-40 wt% of potassic raw material, 50-70wt% of titaniferous raw material and 5-10 wt% of binding agents are uniformly mixed, grinding is conducted after molding and thermal treatment are conducted, and A material with particle size ranging from 0.088-1 mm and B material with particle size smaller than 0.088 mm are obtained. 20-40 wt% of alumina particles, 10-25 wt% of alumina fine powders, 5-15 wt% of A material, 5-15 wt% of B material, 5-15 wt% of aluminiferous raw material and 2-10 wt% of potassic raw material are used as mixture, water containing 2-8 wt% of the micture are added, a green body is made by stirring, drying is conducted, cooling is conducted after the thermal treatment is conducted, the green body is soaked with water, then drying is conducted, and the high-infrared reflectivity high-aluminum light fire-resistant thermal insulating material is obtained. The high-infrared reflectivity high-aluminum light fire-resistant thermal insulating material has the advantages that the volume density is low, the compression strength is high, and the high-temperature heat conductivity coefficient is low. The high-infrared reflectivity high-aluminum light fire-resistant thermal insulating material can also be applied to the heat insulation field within 1300 DEG C for a long time.

Owner:苏安能建筑新材料(苏州)有限公司

Preparation method of aluminum-titanium doped silica airgel/fiber composite

ActiveCN111362664BImprove high temperature resistanceLow thermal conductivity at high temperatureAluminium chlorideSilicic acid

The invention discloses an aluminum-titanium-doped silica airgel / fiber composite material and a preparation method thereof. Anhydrous ethanol, hydrochloric acid solution, aluminum chloride hexahydrate, and tetrabutyl titanate are added to a reaction kettle, Measure tetraethyl orthosilicate and slowly pour it into the reaction kettle, stir to obtain a sol; add a gel accelerator and continue to stir to obtain a composite sol; impregnate the glass fiber mat into the composite sol, and place the impregnated glass fiber mat on a flat plate Lay flat on the top; put the glass fiber mat impregnated with composite sol in a plastic box and seal it for gel aging, and use a solvent to replace the aged gel / glass fiber composite material; gel / glass fiber composite The material is supercritically dried. The invention can enhance the strength and toughness of the aerogel while retaining the heat insulation property of the aerogel, and improve the high-temperature resistance performance of the silica aerogel by doping with aluminum elements, and the prepared airgel / fiber composite material has very high Good stability and thermal insulation properties.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

A kind of high-strength light forsterite refractory material and its preparation method

The invention relates to a high-strength lightweight forsterite fireproof material and a preparation method therefor. The scheme is as follows: the preparation method comprises the steps: firstly, uniformly mixing a siliceous raw material, a magnesium salt, a zinciferous raw material, iron powder and boric acid, carrying out forming, carrying out heat treatment in a reducing atmosphere, and carrying out grinding, thereby obtaining a material A; then, mixing the material A, a surfactant, a thickener, an additive and water, and carrying out ball-milling, thereby obtaining slurry; then, uniformly mixing a siliceous raw material, fine magnesia powder, a zinciferous raw material, municipal sludge and a surfactant, carrying out forming, carrying out heat treatment in a reducing atmosphere, carrying out heat treatment in a neutral atmosphere, and carrying out grinding, so as to obtain a material B and a material C; and finally, uniformly mixing magnesia granules, fine magnesia powder, a siliceous raw material, the material B, the material C, a zinciferous raw material and the slurry, carrying out forming, and carrying out heat treatment, thereby preparing the high-strength lightweight forsterite fireproof material. According to the high-strength lightweight forsterite fireproof material and the preparation method therefor, the source of the raw materials is wide, and the production cost is low; and the prepared product is excellent in high-temperature resistance, high in strength and small in high-temperature coefficient of thermal conductivity and can be used in a long term in high-temperature environments in contact with reducing atmosphere, alkaline dust and the like.

Owner:WUHAN UNIV OF SCI & TECH

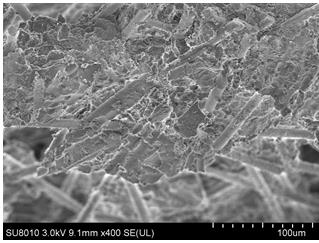

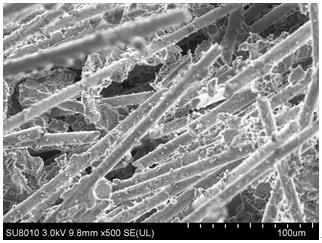

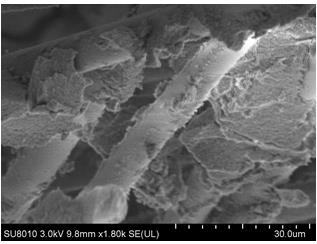

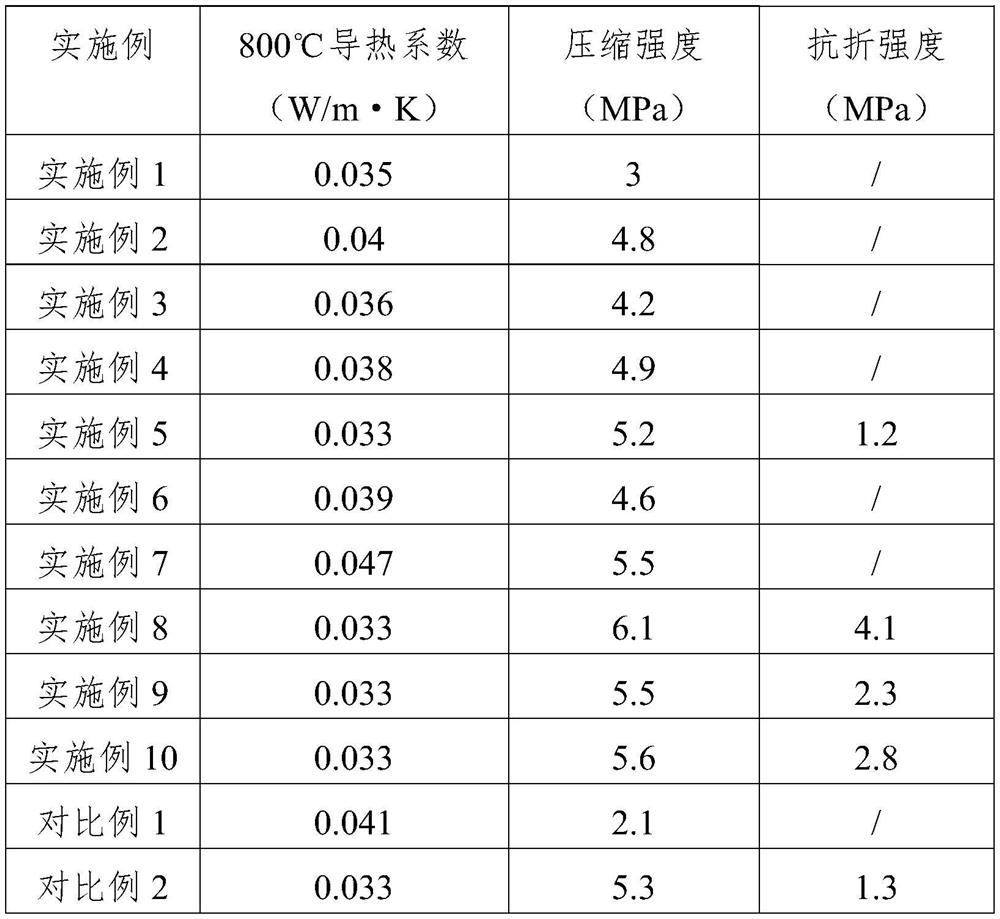

High strength and low thermal conductivity ceramic fiber thermal insulation material and preparation method thereof

The invention relates to a high-strength low-thermal conductivity ceramic fiber thermal insulation material and a preparation method thereof. According to the technical scheme of the high-strength low-thermal conductivity ceramic fiber thermal insulation material and the preparation method thereof, titaniferous raw material, magniferous raw material and binding agents are uniformly mixed, grinding is conducted after molding and thermal treatment are conducted, and A material with particle size ranging from 0.088-1 mm and B material with particle size smaller than 0.088 mm are obtained; potassic raw material, titaniferous raw material and the binding agent are uniformly mixed, grinding is conducted after molding and thermal treatment are conducted, and c material with particle size smaller than 0.088 mm is obtained; then the A material, the B material, the C material and the potassic raw material are mixed uniformly, grinding is conducted after thermal treatment is conducted, and D material with particle size ranging from 0.088-1 mm is obtained; the pretreated ceramic fiber, the B material, the C material, the D material, the binding agent and additive are mixed uniformly, water is added, stirring is conducted, the mixed solution is poured into a die, and the high-strength low-thermal conductivity ceramic fiber thermal insulation material is obtained through the steps of vacuum dewatering, drying and thermal treatment. The high-strength low-thermal conductivity ceramic fiber thermal insulation material and the preparation method thereof have the advantages are low in cost, the prepared product is low in volume density, high in breaking strength and low in high-temperature heat conductivity coefficient.

Owner:WUHAN UNIV OF SCI & TECH

High infrared reflectivity forsterite lightweight refractory insulation material and preparation method thereof

InactiveCN104844240BWide variety of sourcesReduce manufacturing costPolymer scienceThermal insulation

The invention relates to a high-infrared-reflectivity forsterite lightweight refractory and thermal insulation material and a preparation method thereof. According to the technical scheme, the method comprises the following steps: uniformly mixing a titanium-containing raw material, a magnesium-containing raw material and a binding agent, molding, carrying out heat treatment, and grinding, thus obtaining an A material with a particle size of 0.088-1mm and a B material with a particle size of less than 0.088mm; uniformly mixing a potassium-containing raw material, a titanium-containing raw material and a binding agent, molding, carrying out heat treatment, and grinding, thus obtaining a C material with a particle size of 0.088mm; uniformly mixing the A material, the B material, the C material and a potassium-containing raw material, carrying out heat treatment, and grinding, thus obtaining a D material with a particle size of 0.088-1mm and an E material with a particle size of 0.088mm; and finally, mixing forsterite particles, fine forsterite powder, the A material, the D material, the E material, a magnesium-containing raw material, a silicon-containing raw material and a potassium-containing raw material, molding, drying, carrying out heat treatment, cooling, soaking and drying. The prepared high-infrared-reflectivity forsterite lightweight refractory and thermal insulation material is low in volume density, high in compression strength, and low in high-temperature heat conductivity coefficient.

Owner:WUHAN UNIV OF SCI & TECH

Nano ceramic thermal insulation material and preparation method thereof

The invention relates to a nano ceramic thermal insulation material and a preparation method thereof. The preparation method comprises the following steps: preparing a glue solution from superfine lanthanum-based rare earth oxide, an yttrium oxide stabilized nano zirconium oxide auxiliary agent, nano titanium dioxide and nano aluminum oxide aqueous solution, attapulgite hydrosol, silicon dioxide hydrosol and fly ash; and then preparing the nano ceramic thermal insulation material by utilizing the glue solution, magnesium aluminum silicate fibers, sepiolite fabric, vitrified micro beads and power plant floating beads. The prepared material has the advantages of better high temperature resistance, higher strength, better toughness and no pollution.

Owner:烟台德孚瑞环保节能科技有限公司

Phosphoric acid-based nano thermal insulation material and preparation method thereof

ActiveCN113816719AImprove infrared radiation resistance performanceReduce high temperature thermal conductivityFiberO-Phosphoric Acid

The invention relates to a phosphoric acid-based nano thermal insulation material and a preparation method thereof. The method comprises the following steps: (1) performing mechanical fusion on nano powder, ceramic chopped fibers and anti-radiation nanosheets to obtain a dispersed material; (2) adding a phosphoric acid-based solid-state adhesive into the dispersed material, and uniformly mixing to obtain a to-be-filled material; (3) filling the to-be-filled material into a mold, carrying out mold pressing, and demolding to obtain a nano thermal insulation material intermediate; and (4) carrying out curing treatment on the nano thermal insulation material intermediate to prepare the phosphoric acid-based nano thermal insulation material. According to the invention, the phosphoric acid-based solid-state adhesive is selected as a material mechanical strength reinforcing agent, so that the problem that the affinity of a traditional liquid adhesive and a solid-state material is poor is solved, and the problem that a traditional nano thermal insulation material is prone to powder falling and slag falling is effectively solved; and the two-dimensional nanosheets with excellent radiation shielding performance are adopted, so that the infrared radiation resistance of the material is effectively improved, and the high-temperature heat conductivity of the material is reduced.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

High-temperature-resistance and heat-insulation coating and production method thereof

InactiveCN102030540BPhysical state stacking pore volumeLow thermal conductivity at high temperatureAlcoholRefractory

The invention relates to the field of high temperature resistance and heat insulation, in particular to a high-temperature-resistance and heat-insulation coating and the production method thereof. The finished product of the coating comprises the following components: 55 to 80 weight parts of inorganic high-temperature refractory adhesive mortar, 5 to 7 weight parts of SiO2 aerogel, 5 to 7 weight parts of hexapotassium titanate whisker, 3 to 5 weight parts of lamellar mica or lamellar metal and 90 to 120 weight parts of acetone or absolute alcohol. The production method comprises the following steps: a) firstly, screening the SiO2 aerogel containing grains with appropriate size, and pouring the appropriate amount of the acetone or the absolute alcohol into the SiO2 aerogel and fully stirring, wherein the contents of the SiO2 aerogel and the acetone or the absolute alcohol are 5 to 7 weight parts of the SiO2 aerogel and 90 to 120 weight parts of the acetone or the absolute alcohol; and b) adding 3 to 5 weight parts of the lamellar mica or 3 to 5 weight parts of the lamellar metal, 55 to 80 weight parts of the inorganic high-temperature refractory adhesive mortar and 5 to 7 weight parts of the hexapotassium titanate whisker to the mixture prepared in the step a), and fully stirring so as to prepare the high-temperature-resistance and heat-insulation coating. The production method is simple and easy to operate. The high-temperature-resistance and heat-insulation material obtained by using the method has the advantages of good heat insulation effect, high strength and wide prospect on the application.

Owner:武汉阜成科技股份有限公司

Inorganic thermal insulation material

The invention provides an inorganic thermal insulation material, which is prepared by the following raw materials by weight: 2.5-6 parts of attapulgite, 3.5-4.5 parts of perlite, 1.5-5.0 parts of ceramic beads, 0.0-5 parts of palygorskite, 0.0-5.5 parts of sepiolite, 0.5-1.0 part of a fast penetrant T, 0.25-0.75 part of lightweight magnesium carbonate, 1.5-3.5 parts of brucite, 0.25-0.75 part of alumina silicate fiber cotton, 0.5-0.8 part of lithium silicate, 0.7-1.0 part of magnesium oxide, 0.10-0.25 part of titanium dioxide, 0.25-0.75 part of carboxymethyl cellulose and 70-81.25 parts of water. The thermal insulation material of the invention can be used at a temperature ranging from -40DEG C to 800DEG C, and has low thermal conductivity which can be 0.059W / m.k at a temperature of 70DEGC, especially low high temperature thermal conductivity, which can be 0.085W / m.k at a temperature of 350DEG C.

Owner:邓克 +1

High temperature resistant Si-C-O aerogel thermal insulation composite material and preparation method thereof

The invention relates to a high temperature resistant Si-C-O aerogel thermal insulation composite material and a preparation method thereof. The preparation method comprises the following steps: mixing an Si source and a C source, and carrying out hydrolysis and condensation polymerization to form a sol which has a nanometer porous three-dimensional network skeleton structure and contains three elements of Si, C, and O in the network structure; compositing the sol with a high temperature resistant inorganic ceramic fiber to form a fiber-gel mixture; carrying out supercutical fluid drying to obtain an Si-C-O aerogel precursor composite material with the nanometer porous structure; and cracking the Si-C-O aerogel precursor composite material in high temperature inert atmosphere to form the Si-C-O aerogel thermal insulation composite material with an Si-O bond and an Si-C bond coexisting. The thermal conductivities of the Si-C-O aerogel thermal insulation composite material prepared in the invention at 800DEG C, 1000DEG C, and 1200DEG C are low to 0.32W / m.K, 0.043 W / m.K, and 0.051 W / m.K respectively, and the bending strength of the Si-C-O aerogel thermal insulation composite materialis 2.6MPa, so the Si-C-O aerogel thermal insulation composite material can satisfy stringent thermal insulation requirements by aerospace fields, military fields and civil fields.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing aluminum alloy element surface coating and system thereof

ActiveCN102634832BPlay a toughening roleImprove high temperature performanceAnodisationComposite ceramicPre treatment

A method for preparing an aluminum alloy element surface coating comprises the following steps of sequentially pre-treating the aluminum alloy element surface, preparing aluminum alloy element surface arcing-blocking coating, preparing aluminum alloy surface insulation composite ceramic coating and performing post-treatment; the preparation of aluminum alloy element surface arcing-blocking coating is to perform coating in a deionized water electrolyte system composed of NaOH, Na2SiO3, (NaPO3)6 and K2ZrF6; the system for the preparation of aluminum alloy element surface coating comprises a stainless steel solution tank (7), tooling (4), an aluminum alloy element (5), a stirrer (2), a thermometer (6), a water-circulating cooling device (1) and power supply equipment (8). The aluminum alloy member surface coating obtained from the method and the system of the invention has the advantages of high toughness and strong binding capacity with the surface of the aluminum alloy element, long service life and excellent heat insulation performance.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

A kind of calcium silicate fireproof board and preparation method thereof

ActiveCN108069673BLow heat shrinkageLow thermal conductivity at high temperatureCalcium silicateFiber

The invention provides a calcium silicate fireproof board and a preparation method thereof. The calcium silicate fireproof board comprises the following raw materials in parts by weight: 0.1-80 parts of hydrated calcium silicate; 10-70 parts of quartz; 0-20 parts of cement 0-20 parts of wood pulp fiber; 10-70 parts of lime; the calcium-silicon ratio of the raw material is 0.1-5. The preparation method of the calcium silicate fireproof board includes pulping, molding by flow-flow process, steam curing and drying. The calcium silicate fireproof board successfully applies hydrated calcium silicate to the fireproof board, its high-temperature thermal conductivity is less than 0.2W / (M×K), and its thermal shrinkage rate is less than 0.3%. It solves the problem that solid waste-based silicon-containing materials are difficult to use Problem: The preparation method has simple process, mild conditions, low cost and easy industrial application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High infrared reflectivity spinel lightweight refractory insulation material and preparation method thereof

The invention relates to a high-infrared reflectivity spinel light fire-resistant thermal insulating material and a preparation method thereof. According to the scheme of the high-infrared reflectivity spinel light fire-resistant thermal insulating material and the preparation method thereof, titaniferous raw material, magniferous raw material and binding agents are uniformly mixed, grinding is conducted after molding and thermal treatment are conducted, and A material with particle size ranging from 0.088-1 mm and B material with particle size smaller than 0.088 mm are obtained; potassic raw material, titaniferous raw material and the binding agent are uniformly mixed, grinding is conducted after molding and thermal treatment are conducted, and c material with particle size smaller than 0.088 mm is obtained; then the A material, the B material, the C material and the potassic raw material are mixed uniformly, grinding is conducted after thermal treatment is conducted, and D material with particle size ranging from 0.088-1 mm and E material with particle size smaller than 0.088 mm are obtained; finally, the magnesium aluminate spinel particles, magnesium aluminate spinel fine powders, the A material, the D material, the E material, the magniferous raw material, the aluminiferous raw material and the potassic raw material are mixed, water is added, the stirring is conducted, drying is conducted on a green body formed by pressing, the green body is soaked with water after thermal treatment is conducted, and drying is conducted. The prepared product is low in volume density, high in compression strength and low in high-temperature heat conductivity coefficient.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com