Preparation method of aluminum-titanium doped silica airgel/fiber composite

A fiber composite material, silica technology, applied in the field of high temperature thermal insulation materials, can solve the problems of poor mechanical properties, elevated temperature, low melting point, etc., achieve good stability and thermal insulation performance, enhance strength and toughness, improve The effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

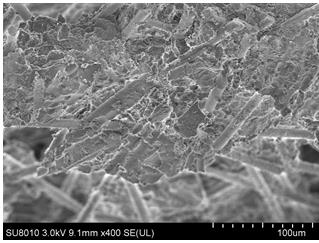

[0029] Embodiment 1: see figure 1 , figure 2

[0030] A preparation method of aluminum-titanium doped silica airgel / fiber composite material, comprising the following steps:

[0031] 1) Measure 2000 mL of absolute ethanol, 1000 mL of 0.01 mol L -1 Hydrochloric acid, weigh 100 g aluminum chloride hexahydrate and 50 g tetrabutyl titanate, add the above raw material reagents into the reaction kettle together, stir until completely dissolved; measure 1000 mL ethyl orthosilicate and add to the above mixed solution, Control the stirring time for 5 h to obtain a sol; slowly add 500 mL of 1,2-propylene oxide to the sol, and continue stirring for 5 min to obtain an aluminum-titanium-doped silica composite sol;

[0032] 2) Impregnate the cut high-silica glass fiber mat of 30 cm×30 cm×3 cm into the composite sol, take it out after the impregnation is complete, and lay the impregnated glass fiber mat on a flat plate; finish the impregnation Put the glass fiber mat into a plastic box ...

Embodiment 2

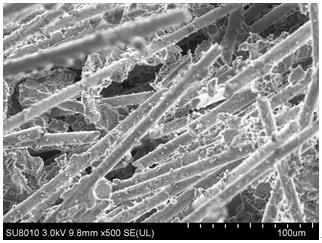

[0035] Embodiment 2: see image 3 , Figure 4

[0036] A preparation method of aluminum-titanium doped silica airgel / fiber composite material, comprising the following steps:

[0037] The main steps are the same as in Example 1, except that step 1) Weigh 50 g of aluminum chloride hexahydrate and 24 g of tetrabutyl titanate, and finally obtain an aluminum doping amount of 5 wt% silicon element, titanium element doping Aluminum-titanium doped silica airgel / fiber composite with 3 wt% silicon element.

[0038] The prepared aluminum-titanium-doped silica airgel / fiber composite has a smooth and wrinkle-free appearance, and the airgel and glass fiber are well combined, and the thermal conductivity is 0.030~0.035 W / (m∙K) at 25°C. The thermal conductivity at high temperature is 0.101~0.110 W / (m∙K).

Embodiment 3

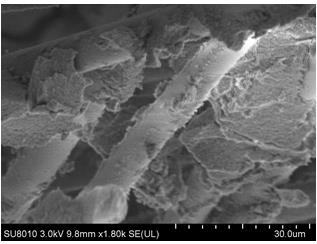

[0039] Embodiment 3: see Figure 5 , Figure 6

[0040] The main steps are the same as in Example 1, except that step 1) Weigh 150 g of aluminum chloride hexahydrate and 80 g of tetrabutyl titanate, and finally obtain an aluminum doping amount of 15 wt% silicon element, titanium element doping Aluminum-titanium doped silica airgel / fiber composite with 10 wt% silicon element.

[0041] The prepared aluminum-titanium-doped silica airgel / fiber composite has a flat and wrinkle-free appearance, and the combination of airgel and glass fiber is good, and the thermal conductivity is 0.033~0.037 W / (m∙K) at 25°C. The thermal conductivity at high temperature is 0.100~0.105 W / (m∙K).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com