Composition, porous carbon fiber thermal insulation material high-surface-emissivity anti-oxidation coating prepared from composition and preparation method of porous carbon fiber thermal insulation material high-surface-emissivity anti-oxidation coating

A technology of porous carbon fiber and anti-oxidation coating, which is applied in applications, ceramic products, household appliances, etc., can solve the problems of lowering the coating formation temperature, and achieve the effects of lowering the sintering temperature, improving the attenuation of radiation performance, and lowering the preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

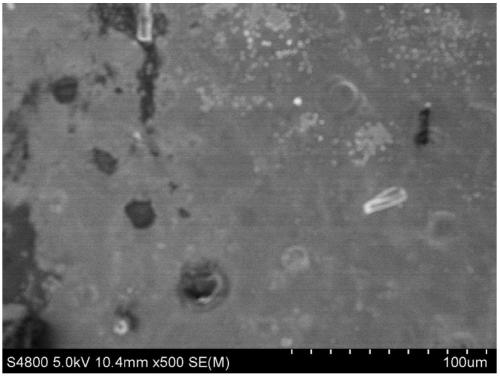

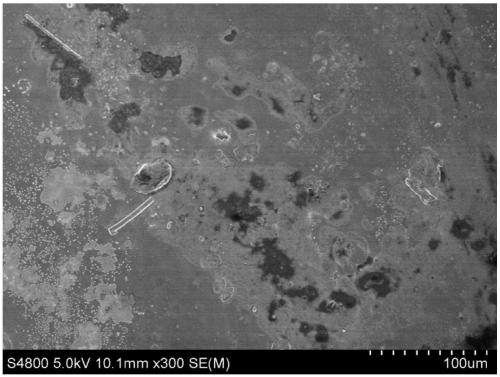

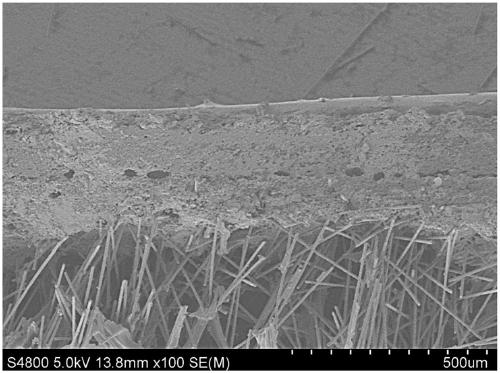

Image

Examples

preparation example Construction

[0065] Specifically, the preparation method comprises the steps:

[0066] (1) Preparation of slurry for brushing

[0067] The above-mentioned composition provided by the present invention is mixed with an organic solvent capable of dissolving polycarbosilane to prepare a slurry; in order to obtain a slurry with suitable viscosity, the usage amount of the organic solvent satisfies the following conditions: mixing the organic solvent and polycarbosilane The mass percentage content of polycarbosilane in the solution is 5 to 30%, for example, 5%, 10%, 15%, 20%, 25% or 30%.

[0068] In the present invention, the type of the organic solvent is not particularly limited, but xylene or divinylbenzene is preferably used.

[0069] In the process of preparing the slurry, polycarbosilane (PCS) can be ground into powder first, and then dissolved in an organic solvent to prepare a PCS solution with a PCS content (mass percentage) of 5-30%, and then The other components in the composition (...

Embodiment 1

[0083] (1) Dissolve cerium nitrate in deionized water with magnetic stirring, and the concentration of cerium oxide is 0.5 mol / L. Using citric acid as a catalyst, the molar ratio of cerium nitrate and citric acid was 1:2, and the gel was prepared by stirring in a water bath at 60 °C for 3 h. The obtained gel was dried at 120 °C for 12 h, then calcined at 500 °C for 2 h, ball-milled and sieved to obtain cerium oxide nanopowder.

[0084] (2) The porous carbon fiber thermal insulation material was cut into 3.0cm×3.0cm×1.0cm fiberboard, and polished with 500-mesh, 1000-mesh, 2000-mesh, and 3000-mesh SiC sandpaper, ultrasonically cleaned for 20min, and dried in an oven at 80°C for later use.

[0085] (3) grinding the polycarbosilane into powder, dissolving the ground polycarbosilane (PCS) powder into a xylene solution to prepare a PCS solution, and the PCS content in the solution is 10% (mass percentage); Hafnium Boride (HfB 2 ), molybdenum silicide (MoSi 2 ), silicon carbide (S...

Embodiment 2

[0089] (1) Dissolve cerium nitrate in deionized water with magnetic stirring, and the concentration of cerium oxide is 1 mol / L. Using citric acid as a catalyst, the molar ratio of cerium nitrate and citric acid was 1:2, and the gel was prepared by stirring in a water bath at 60 °C for 4 h. The obtained gel was dried at 120 °C for 12 h, then calcined at 500 °C for 2 h, ball-milled and sieved to obtain cerium oxide nanopowder.

[0090] (2) The porous carbon fiber thermal insulation material was cut into 3.0cm×3.0cm×1.0cm fiberboard, and polished with 500-mesh, 1000-mesh, 2000-mesh, and 3000-mesh SiC sandpaper, ultrasonically cleaned for 20min, and dried in an oven at 80°C for later use.

[0091] (3) grinding the polycarbosilane into powder, dissolving the ground polycarbosilane (PCS) powder into a xylene solution to prepare a PCS solution, and the PCS content in the solution is 10% (mass percentage); Hafnium Boride (HfB 2 ), molybdenum silicide (MoSi 2 ), silicon carbide (SiC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com