Phosphoric acid-based nano thermal insulation material and preparation method thereof

A phosphoric acid-based nanometer, heat insulating material technology, applied in the field of nanometer heat insulating material preparation, can solve the problems of high temperature radiation shielding performance and mechanical strength need to be further improved, weak physical assembly particle force, high high temperature thermal conductivity and other problems, and achieves improvement. The effect of mechanical properties and thermal insulation properties, improving infrared radiation resistance, and reducing high temperature thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

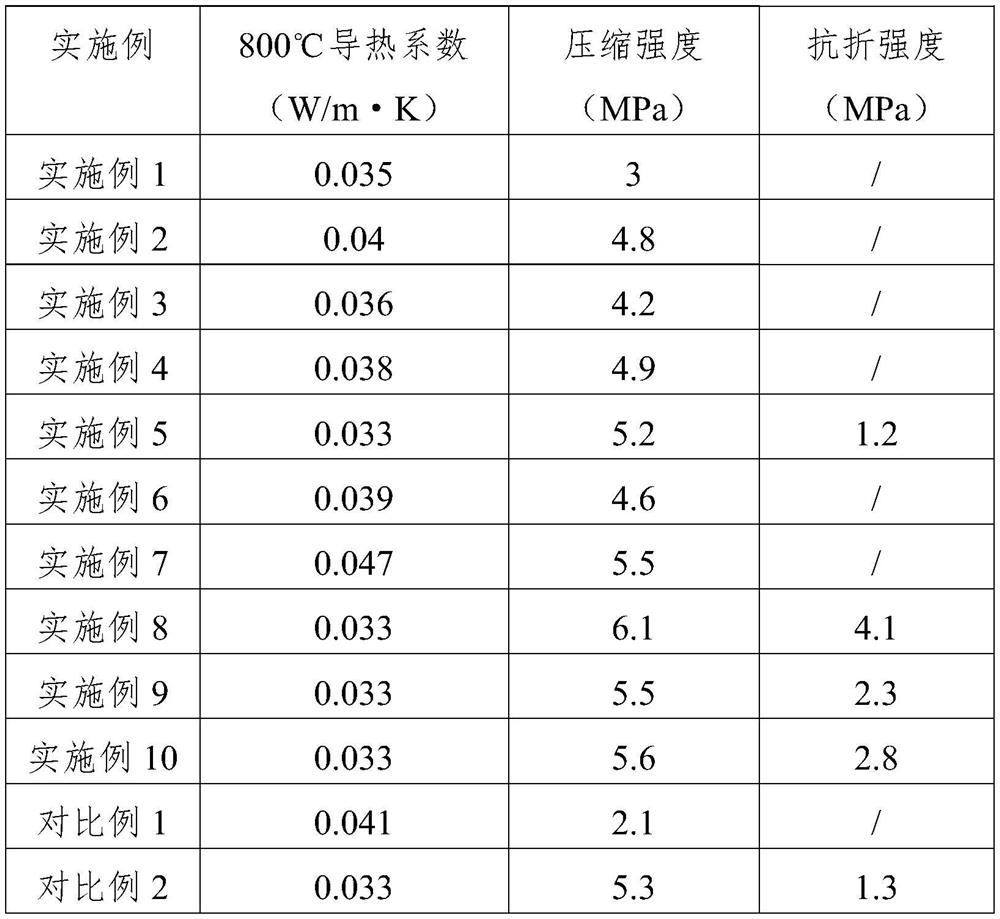

Examples

preparation example Construction

[0024] The preparation method of the phosphoric acid-based nano-insulation material in the present invention mainly uses nano-powder, ceramic chopped fiber, anti-radiation nanosheet and phosphoric acid-based solid adhesive as raw materials; the main preparation steps are as follows: nano-powder, ceramic chopped Uniform dispersion of fibers and anti-radiation nanosheets, effective fusion of phosphoric acid-based solid binders, molding and drying and curing treatments, etc.

[0025] The present invention provides a method for preparing a phosphoric acid-based nano-insulation material in a first aspect, said method comprising the steps of:

[0026] (1) Mechanical fusion of nanopowder, ceramic chopped fibers and radiation-resistant nanosheets to obtain dispersed materials; the present invention has no special restrictions on the conditions for mechanical fusion, and adopts existing mechanical fusion commonly used for dispersed materials All conditions are acceptable, as long as a ...

Embodiment 1

[0052] (1) Weigh 5 parts by mass of high-silica chopped fibers, 90 parts by mass of silicon oxide nanopowder and 5 parts by mass of cerium oxide nanosheets, place them in a mechanical fusion device, stir and disperse evenly to obtain dispersed materials.

[0053] (2) Add 5 parts by mass of solid aluminum dihydrogen phosphate (phosphate-based solid binder) to the dispersed material obtained in step (1), and continue stirring through mechanical fusion equipment to uniformly disperse solid aluminum dihydrogen phosphate in the dispersed Among the materials, the materials to be loaded are obtained.

[0054] (3) Fill the material to be filled obtained in step (2) into a forming mold, send it into a hydraulic press, and mold it under a pressure of 0.5 MPa for 30 minutes, and then demould the material to obtain a nano-insulation material intermediate.

[0055] (4) Put the intermediate nano-insulation material obtained in step (3) into an oven, and cure at 120° C. for 3 hours to prepar...

Embodiment 2

[0057] (1) Weigh 5 parts by mass of quartz chopped fibers, 60 parts by mass of silica nanopowder and 35 parts by mass of mica nanosheets, place them in a mechanical fusion device, stir and disperse evenly to obtain dispersed materials.

[0058] (2) Add 20 parts by mass of solid aluminum dihydrogen phosphate (phosphate-based solid binder) to the dispersed material obtained in step (1), and continue stirring through mechanical fusion equipment to uniformly disperse solid aluminum dihydrogen phosphate in the dispersed Among the materials, the materials to be loaded are obtained.

[0059] (3) Fill the material to be filled obtained in step (2) into a forming mold, send it into a hydraulic press, and mold it under a pressure of 2 MPa for 90 minutes, and then demould the material to obtain a nano-insulation material intermediate.

[0060] (4) Put the intermediate nano-insulation material obtained in step (3) into an oven, and cure at 150° C. for 3 hours to prepare a phosphoric acid-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com