A kind of heat-resistant sicob airgel thermal insulation composite material and preparation method thereof

A composite material and aerogel technology, applied in the field of heat insulation materials, can solve problems such as limiting the application of SiCO airgel materials, poor high temperature oxidation resistance, and affecting heat insulation effects, so as to improve the ability to block infrared radiation at high temperatures, Effect of reducing solid-state thermal conductivity and improving high-temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

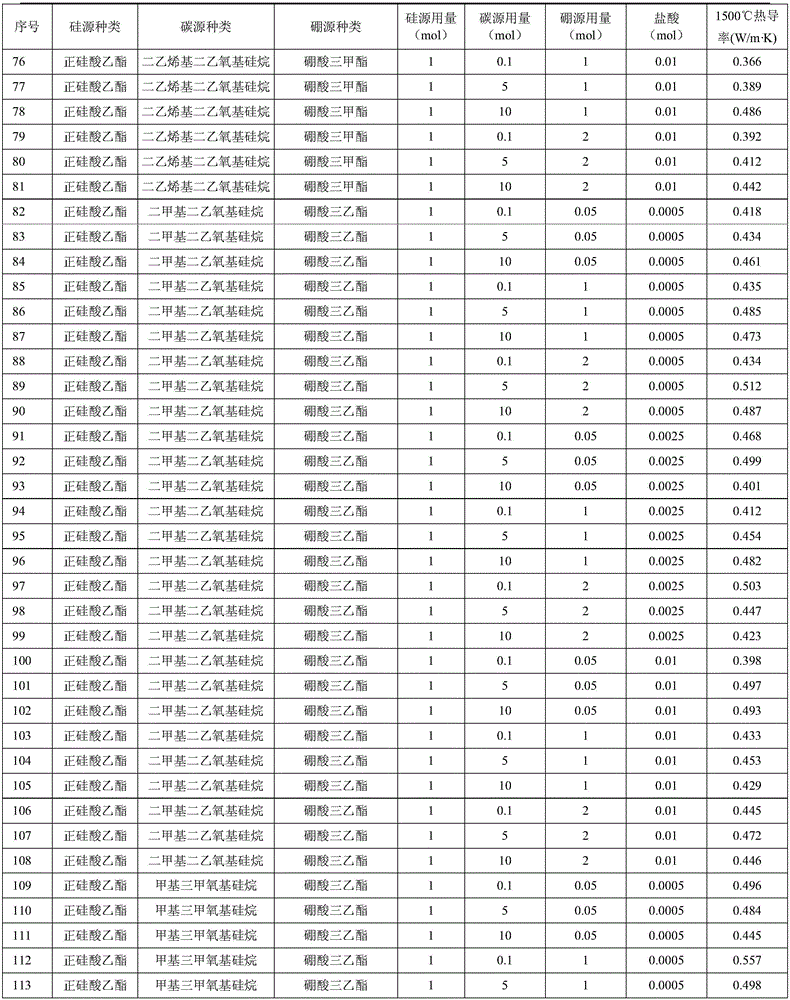

Embodiment 1

[0037] The product of this embodiment is made of carbon fiber and SiCOB airgel.

[0038] (1) Sol preparation: first, the molar ratio of ethyl orthosilicate, dimethyldiethoxysilane, and hydrochloric acid is 1:1:0.0025; mix and stir at room temperature for 1 hour, so that the silicon source and the carbon source are Fully hydrolyzed in the environment; then add methyl orthoborate and continue to stir for 2 hours to obtain the SiCOB precursor sol;

[0039] (2) Preparation of fiber prefabricated parts: the apparent density of the designed fiber prefabricated parts is 0.15g / cm 3 , according to mass=volume×density, calculate the fiber mass, weigh the carbon fiber, make the fiber arrangement direction perpendicular to the heat flow direction during heat insulation, clamp and fix the fiber with a mold, and obtain a carbon fiber prefabricated part;

[0040] (3) Preparation of gel / fiber preform mixture: place the fiber preform in a sealed impregnation tank, evacuate to a vacuum of 0.00...

Embodiment 2

[0045] The product of this embodiment is made of mullite fiber and SiCOB airgel.

[0046] (1) Sol preparation: first, the molar ratio of ethyl orthosilicate, dimethyldiethoxysilane, and hydrochloric acid is 1:1:0.0009; mix and stir at room temperature for 6 hours, so that the silicon source and the carbon source are Fully hydrolyzed in the environment; then add methyl orthoborate and continue to stir for 8 hours to obtain the SiCOB precursor sol;

[0047] (2) Preparation of fiber prefabricated parts: the apparent density of the designed fiber prefabricated parts is 0.25g / cm 3 , according to mass=volume×density, calculate the fiber mass, weigh the carbon fiber, make the fiber arrangement direction perpendicular to the heat flow direction during heat insulation, clamp and fix the fiber with a mold, and obtain a carbon fiber prefabricated part;

[0048] (3) Preparation of gel / fiber preform mixture: place the fiber preform in a sealed impregnation tank, evacuate to a vacuum of 0....

Embodiment 3

[0053] The product of this embodiment is made of zirconia fiber and SiCOB airgel.

[0054] (1) Sol preparation: first, the molar ratio of ethyl orthosilicate, dimethyldiethoxysilane, and hydrochloric acid is 1:1:0.0075; mix and stir at room temperature for 3 hours, so that the silicon source and the carbon source are Fully hydrolyzed in the environment; then add methyl orthoborate and continue to stir for 4 hours to obtain the SiCOB precursor sol;

[0055] (2) Preparation of fiber prefabricated parts: the apparent density of the designed fiber prefabricated parts is 0.15g / cm 3 , according to mass=volume×density, calculate the fiber mass, weigh the zirconia fiber, make the fiber arrangement direction perpendicular to the heat flow direction during heat insulation, clamp and fix the fiber with a mold, and obtain a carbon fiber prefabricated part;

[0056] (3) Preparation of gel / fiber preform mixture: place the fiber preform in a sealed impregnation tank, evacuate to a vacuum of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com