Nano thermal-insulation paint and preparation method thereof

A thermal insulation coating and nanotechnology, applied in the field of coatings, can solve the problems of poor high temperature resistance, restriction, coating peeling, etc., and achieve the effect of reducing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

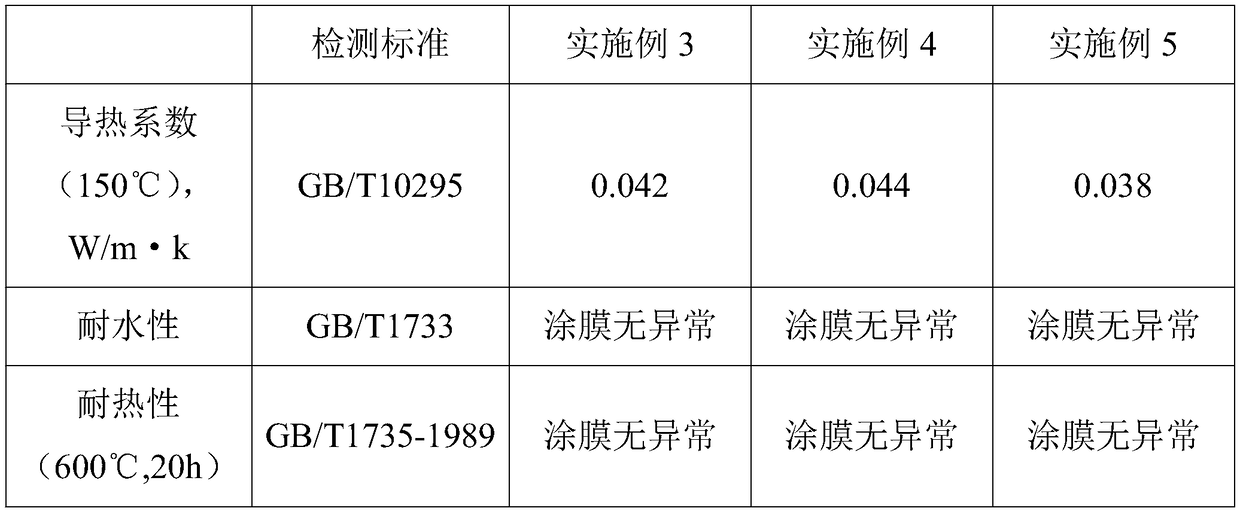

Examples

Embodiment 1

[0022] The preparation method of modified aluminum silicate fiber comprises the following steps:

[0023] Add aluminum silicate fibers into water for ultrasonic dispersion to obtain a dispersion, then heat up to 75°C, then add silane coupling agent A-171 and chitosan, react for 12 hours, and then dry after the reaction. The mass ratio of aluminum silicate fiber to chitosan is 3:1, and the mass ratio of aluminum silicate fiber to silane coupling agent A-171 is 24:1.

Embodiment 2

[0025] The preparation method of modified aluminum silicate fiber comprises the following steps:

[0026] Add aluminum silicate fibers into water for ultrasonic dispersion to obtain a dispersion, then heat up to 85°C, then add silane coupling agent KH560 and chitosan, react for 6 hours, and then dry after the reaction. The mass ratio of aluminum silicate fiber to chitosan is 6:1, and the mass ratio of aluminum silicate fiber to silane coupling agent KH560 is 18:1.

Embodiment 3

[0028] A kind of nano thermal insulation coating, calculates according to parts by weight, comprises the following components:

[0029] 26 parts of silicon-acrylic emulsion, 8 parts of water-based fluorocarbon emulsion, 7 parts of nano-zirconia, 12 parts of silica airgel, 8 parts of modified aluminum silicate fiber in Example 1, 9 parts of alumina crystal fiber, nano-pearl 15 parts of rock, 2 parts of ammonium acrylate dispersant, 2 parts of modified ammonium polyacrylate, 0.6 part of polydimethylsiloxane solution and 20 parts of water.

[0030] Preparation method of nano thermal insulation coating:

[0031] 1) Add ammonium acrylate dispersant and 1 / 2 mass polydimethylsiloxane solution into water according to the formula amount, and stir and mix thoroughly at a speed of 500r / min;

[0032] 2) add silica airgel, the modified aluminum silicate fiber of embodiment 1 and nano-perlite to the mixture of step 1) and disperse at a rotating speed of 1600r / min;

[0033] 3) Add silicone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com