Preparation method of carbon nanofiber aerogel composite

A technology of carbon nanofibers and composite materials, which is applied in the field of preparation of carbon nanofiber aerogel composite materials, can solve the problems of uneven grid structure, high thermal conductivity at high temperature, poor mechanical properties, etc., and reduce thermal conductivity. , The effect of improving mechanical strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

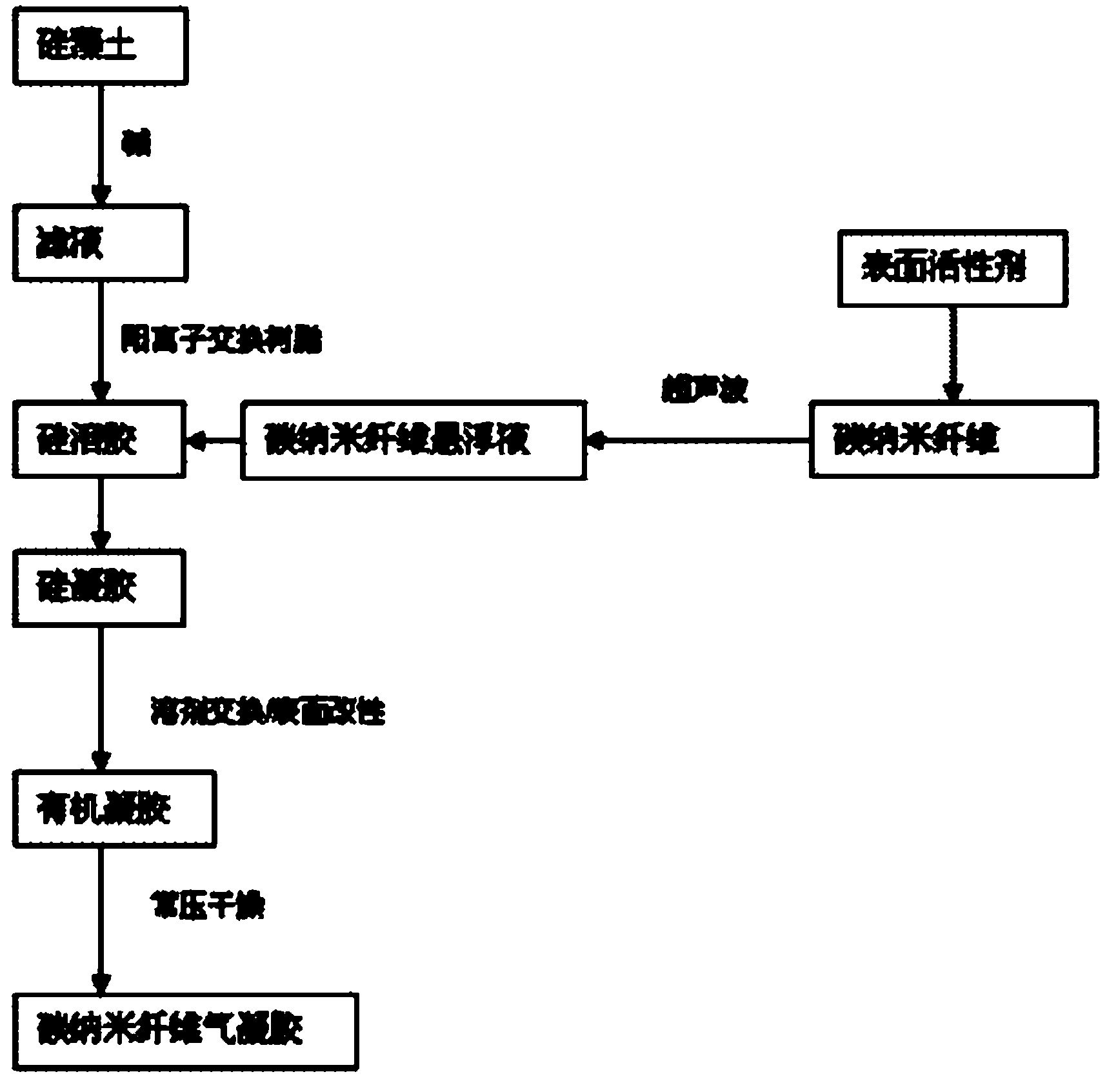

Method used

Image

Examples

Embodiment 1

[0022] The raw materials and properties used are as follows:

[0023] Diatomaceous earth: 200 mesh sieve, SiO 2 Content 90%, loss on ignition 1.3%;

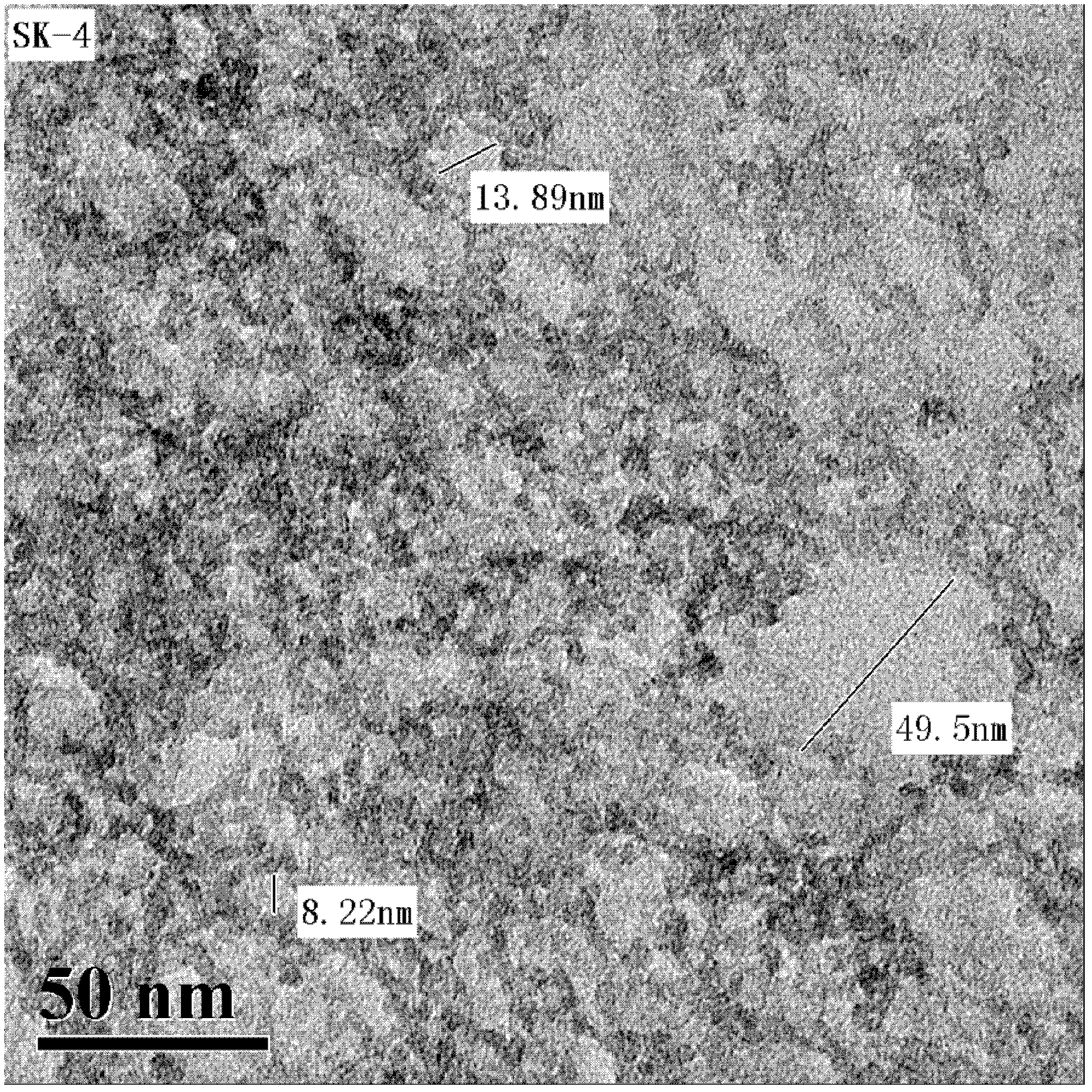

[0024] Carbon nanofiber: diameter 200-600nm, length 5-50um, purity 95%;

[0025] Cation exchange resin: Purite 732 type; NaOH: analytical pure AR grade; ammonia water: 1mol / L; ethanol: AR; n-hexane: AR; trimethylchlorosilane: AR;

[0026] Add 50g of diatomaceous earth to 150mL of 10% NaOH solution, react at 80°C for 150min, filter the filtrate, dilute it with distilled water at a ratio of 1:1, pass it through a cationic resin, control the pH to 2-3, add the volume of the sol 5% carbon nanofiber solution pre-dispersed by ultrasound for 30 min, titrated with ammonia water to pH = 5, the resulting hydrogel was aged at 30 °C for 24 h, and then solvent exchange / surface was performed with ethanol, n-hexane, and trimethylchlorosilane For modification, the molar ratio of ethanol to trimethylchlorosilane is 2:3, the volume ratio of tri...

Embodiment 2

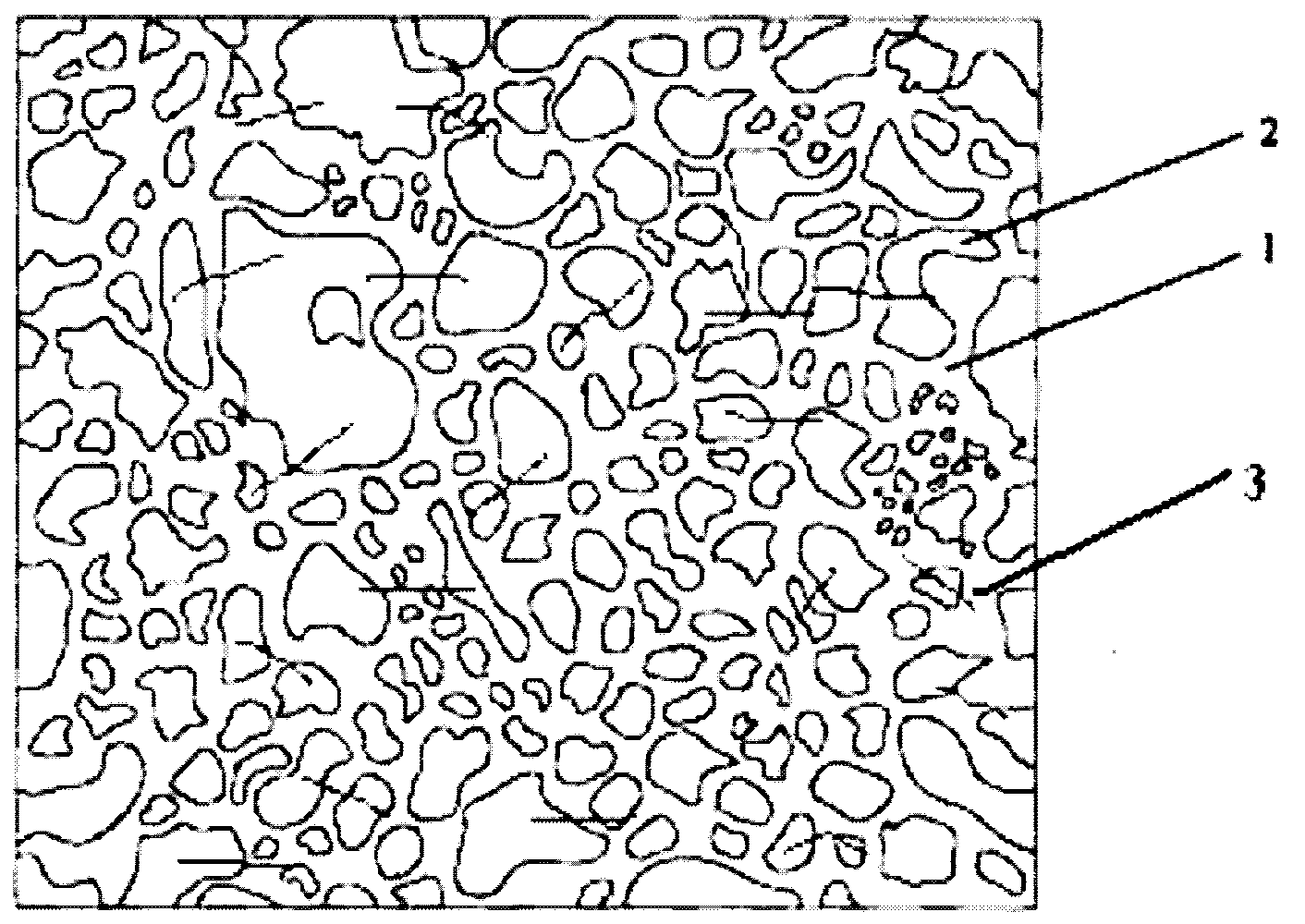

[0028] Add 50g of diatomaceous earth to 180mL of 15% NaOH solution, react at 90°C for 120min, filter the filtrate, dilute it with distilled water at a ratio of 1:3, pass it through a cationic resin, control the pH to 2-3, add the volume of the sol 10% of the carbon nanofiber solution pre-dispersed by ultrasound for 30 min was titrated to pH = 6 with ammonia water, and the resulting hydrogel was aged at 30 °C for 48 h, and then solvent exchange / surface was performed with ethanol, n-hexane, and trimethylchlorosilane For modification, the molar ratio of ethanol to trimethylchlorosilane is 1:1, the volume ratio of trimethylchlorosilane to wet gel is 1:1.5, and the time is 48h. Then place it in an oven at 80°C for 4 hours, and dry it at 150°C for 1 hour to obtain a black carbon nanofiber airgel with a specific surface area of 532.4m 2 / g, the density is 0.197g / cm 3 , The average pore diameter of the internal micropores is 18nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com