Method for preparing silicon dioxide/graphene composite aerogel and composite aerogel obtained thereby

A graphene composite and silicon dioxide technology, applied in the field of airgel, can solve the problems of long steps, high cost, and insufficient heat insulation performance, so as to improve heat insulation performance, low high temperature thermal conductivity, and save equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

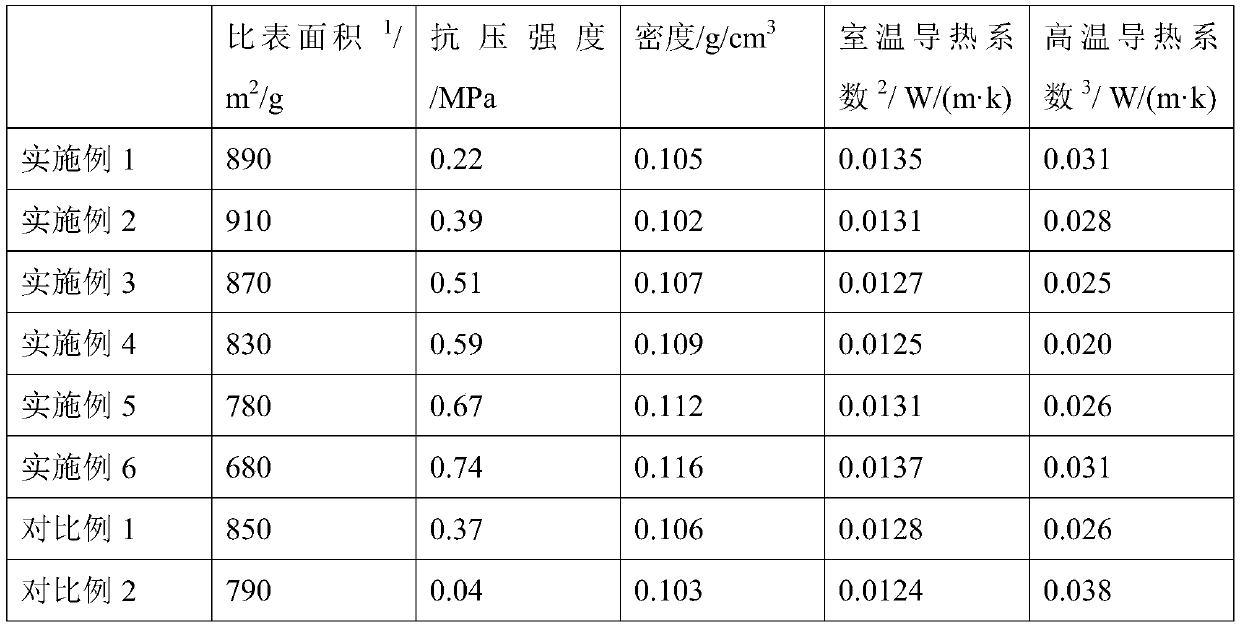

Examples

Embodiment 1

[0034] At room temperature, ultrasonically disperse 0.05 g of ethoxysilanized graphene 1 in 50 ml of acetone, add 0.1 mol / L oxalic acid aqueous solution to adjust the pH to 3.5 for hydrolysis, and obtain hydrolyzate 1A.

[0035] At room temperature, 100 g of tetraethyl orthosilicate, 600 g of acetone and 35 g of deionized water were mixed, and oxalic acid was added to adjust the pH to 3.5 for hydrolysis to obtain hydrolyzate 1B.

[0036] Mix the hydrolyzate 1A and the hydrolyzate 1B evenly, add ammonia water to adjust the pH to 11.0 to condense to obtain a wet gel; place the wet gel in a water bath at 30°C for aging for 4 hours, take out the wet gel and soak it in absolute ethanol for 2 Carry out solvent replacement every hour, solvent replacement is carried out 3 times, take out wet gel again and soak in the n-hexane solution of trimethylchlorosilane (the volume ratio of trimethylchlorosilane and n-hexane is 1:7) in 3 hours, take out wet gel Gel was dried by freeze-drying met...

Embodiment 2

[0038] At room temperature, ultrasonically disperse 0.2 g of ethoxysilanized graphene 2 in 60 ml of absolute ethanol, add 0.1 mol / L oxalic acid aqueous solution to adjust the pH to 3.0 for hydrolysis, and obtain hydrolyzate 2A.

[0039] At room temperature, 100 g of ethyl orthosilicate, 600 g of absolute ethanol and 35 g of deionized water were mixed, and oxalic acid was added to adjust the pH to 3.5 for hydrolysis to obtain hydrolyzate 2B.

[0040]Mix hydrolyzate 2A and hydrolyzate 2B evenly, add ammonia water to adjust the pH to 11.0 and condense to obtain a wet gel; place the wet gel in a water bath at 30°C for aging for 4 hours, take out the wet gel and soak it in absolute ethanol for 1.5 Carry out solvent replacement every hour, solvent replacement is carried out 3 times, take out wet gel again and soak in the n-hexane solution of trimethylchlorosilane (the volume ratio of trimethylchlorosilane and n-hexane is 1:7) in 3 hours, take out wet gel The gel was sequentially dri...

Embodiment 3

[0042] At room temperature, ultrasonically disperse 0.4 g of ethoxysilanized graphene 3 in 70 ml of absolute ethanol, add 0.1 mol / L oxalic acid aqueous solution to adjust the pH to 3.0 for hydrolysis, and obtain hydrolyzate 3A.

[0043] Mix hydrolyzate 3A and hydrolyzate 2B evenly, add ammonia water to adjust the pH to 11.0 to condense to obtain a wet gel; place the wet gel in a water bath at 40°C for aging for 3.5 hours, take out the wet gel and soak it in absolute ethanol for 2 Carry out solvent replacement every hour, solvent replacement is carried out 3 times, take out wet gel again and soak in the n-hexane solution of trimethylchlorosilane (the volume ratio of trimethylchlorosilane and n-hexane is 1:7) in 3 hours, take out wet gel The gel was sequentially dried in a blast drying oven at 40°C for 2.5 hours, in a blast drying oven at 80°C for 2.5 hours, and in a blast drying oven at 120°C for 1.5 hours to obtain a silica-graphene composite airgel 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com