Easy-to-weld modified polypropylene composite with oil resistance and high oxygen index and preparation method of composite

A high oxygen index, composite material technology, applied in the field of polymer materials, can solve the problems of small loss coefficient, poor high frequency welding performance of materials, limited application scope and potential, etc., to achieve low burning speed, excellent welding performance, process operation Easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

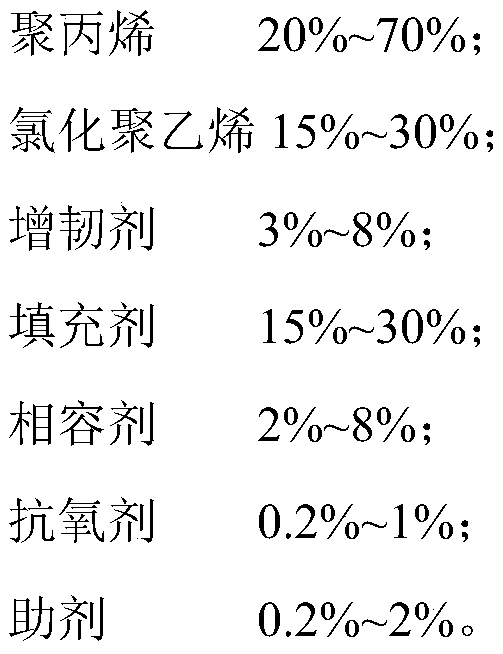

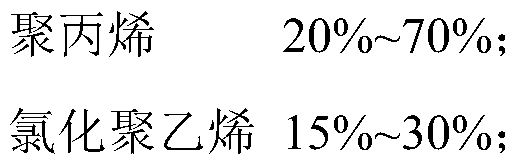

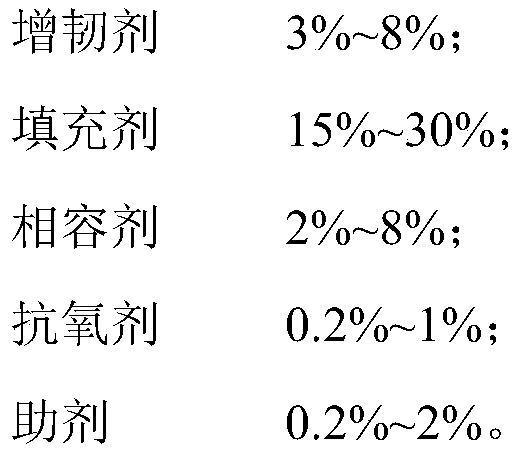

[0044] The preparation method of the oil-resistant, high-oxygen index and easy-to-weld modified polypropylene composite material comprises the following steps:

[0045] 1) Weigh the raw materials according to the aforementioned composition, firstly mix the polypropylene, chlorinated polyethylene and toughening agent uniformly, then add compatibilizer, antioxidant and auxiliary agent to continue mixing to obtain the mixed material;

[0046] 2) Add the mixed material to the main feeding port of the twin-screw extruder, add the filler to the side feeding port of the twin-screw extruder, melt and blend under the protection of nitrogen or other inert gases, and then extrude through the twin-screw extruder It is extruded out of the machine and granulated to obtain a modified polypropylene composite material with oil resistance, high oxygen index and easy welding.

[0047] Preferably, in the step 1) of the preparation method, the mixing is stirring and mixing in a mixer, the stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com