Yttrium silicate modified silicon carbide fiber reinforced silicon carbide composite material and preparation method thereof

A technology of silicon carbide fiber and composite material, which is applied in the field of aerospace material preparation to achieve the effects of maintaining stability, increasing service life and excellent anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

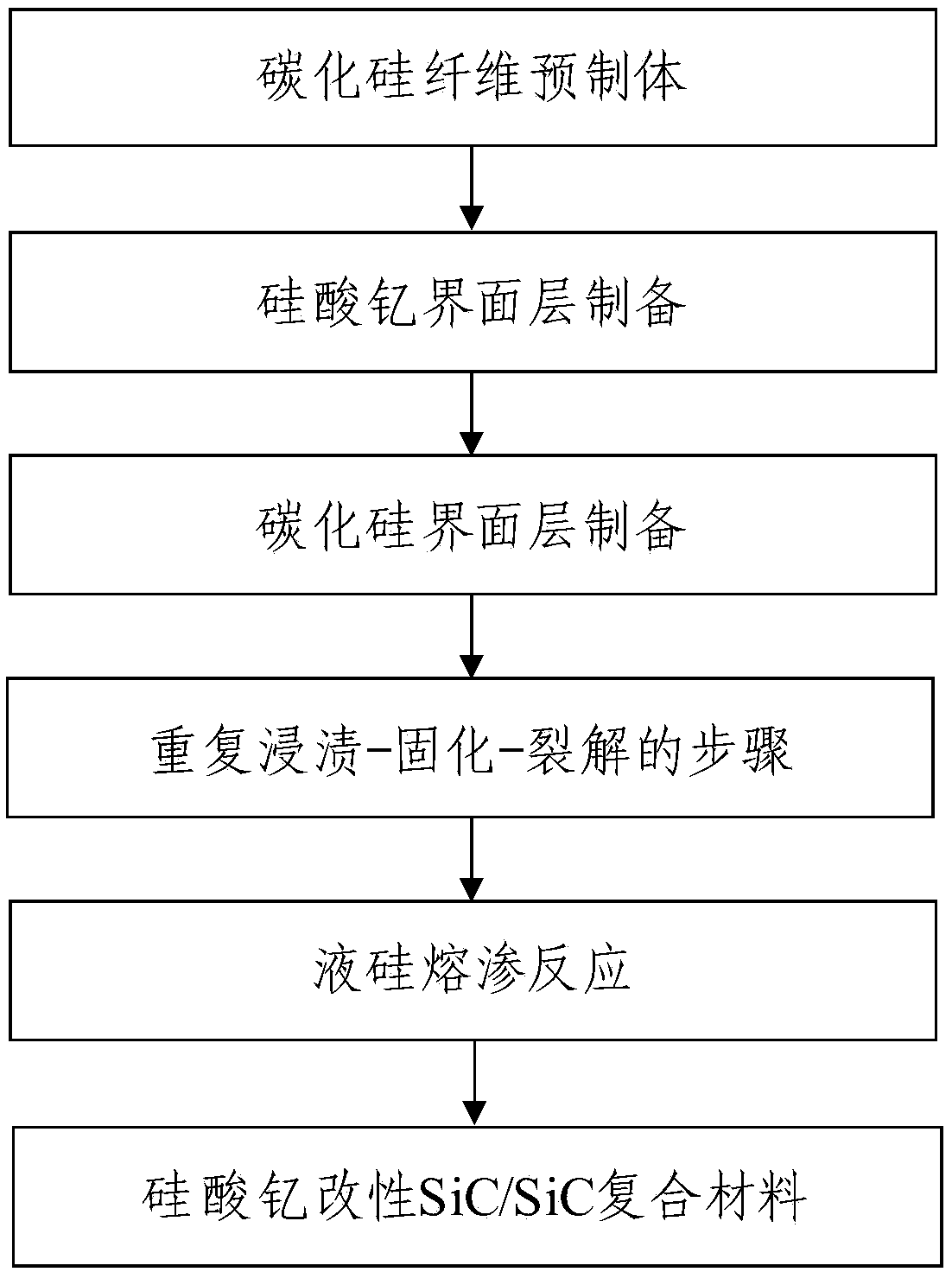

[0030] In the first aspect, the present invention provides a preparation method of yttrium silicate modified silicon carbide fiber reinforced silicon carbide composite material, the method includes the following steps:

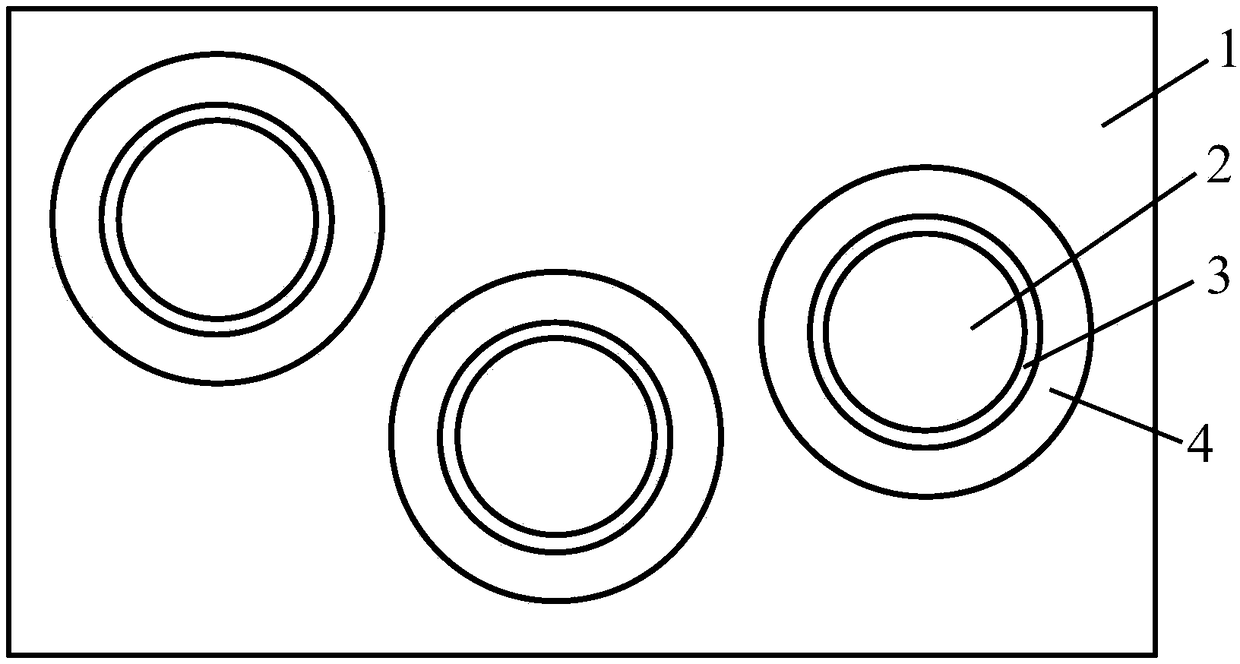

[0031] (1) A layer of yttrium silicate interface layer and a layer of silicon carbide interface layer are sequentially prepared on the surface of the silicon carbide fiber preform (SiC fiber preform) to obtain the yttrium silicate modified silicon carbide fiber preform;

[0032] (2) Impregnating the yttrium silicate modified silicon carbide fiber preform prepared in step (1) with a carbon precursor solution, and then the impregnated yttrium silicate modified silicon carbide fiber preform is sequentially subjected to a curing step and cracking step;

[0033] (3) Repeat step (2) at least once to prepare a porous silicon carbide fiber preform; and

[0034] (4) The porous silicon carbide fiber preform prepared in step (3) is subjected to liquid silicon infiltration reacti...

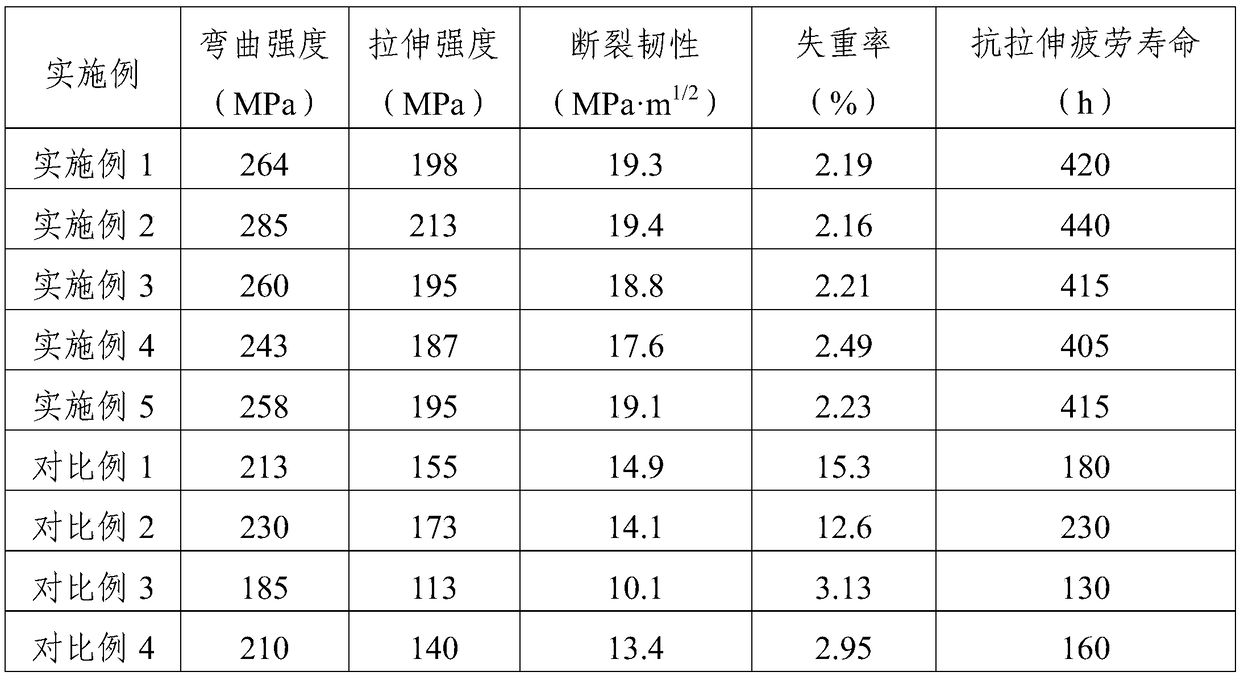

Embodiment 1

[0066] ①Weave the third-generation SiC fiber (Tyranno SA) into a 2.5D silicon carbide fiber preform to obtain a silicon carbide fiber preform with a fiber volume fraction of 35%, with a warp density of 8 strands / cm and a weft density of 3.5 strands / cm.

[0067] ② Mix 1.3 parts of ethyl orthosilicate, 50 parts of water and 18 parts of ethanol, add concentrated hydrochloric acid, and add 6g of concentrated hydrochloric acid to 1 mole of ethyl orthosilicate and stir for 1 hour; then add 2 parts of yttrium chloride hexahydrate and stir for 2 hours. Add 2 parts of propylene oxide and stir for 20 minutes to obtain a precursor sol solution; put the silicon carbide fiber preform in ① into the precursor sol solution for 10 minutes, take it out and put it in an oven at 80°C for 24 hours; finally take out the dried all The silicon carbide fiber preform was heat-treated in a muffle furnace at 1200° C. for 1 hour and taken out to obtain a 600nm thick yttrium silicate (Y) on the surface of the ...

Embodiment 2

[0074] ①Weave the third-generation SiC fiber (Tyranno SA) into a 2.5D silicon carbide fiber preform to obtain a silicon carbide fiber preform with a fiber volume fraction of 39%, with a warp density of 8 fibers / cm and a weft density of 3.5 fibers / cm.

[0075] ② Mix 1.5 parts of ethyl orthosilicate, 60 parts of water and 20 parts of ethanol, add concentrated hydrochloric acid, 1 mole of ethyl orthosilicate, add 7g of concentrated hydrochloric acid, and stir for 1h; then add 3 parts of yttrium chloride hexahydrate and stir for 2h, Add 3 parts of propylene oxide and stir for 20 minutes to obtain a precursor sol solution; put the silicon carbide fiber preform in ① into the precursor sol solution for 15 minutes, take it out and put it in an oven at 80°C for 24 hours; finally take out the dried all The silicon carbide fiber preform was heat-treated in a muffle furnace at 1200° C. for 1 h, and then taken out, so that yttrium silicate (Y) with a thickness of 800 nm was obtained on the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com