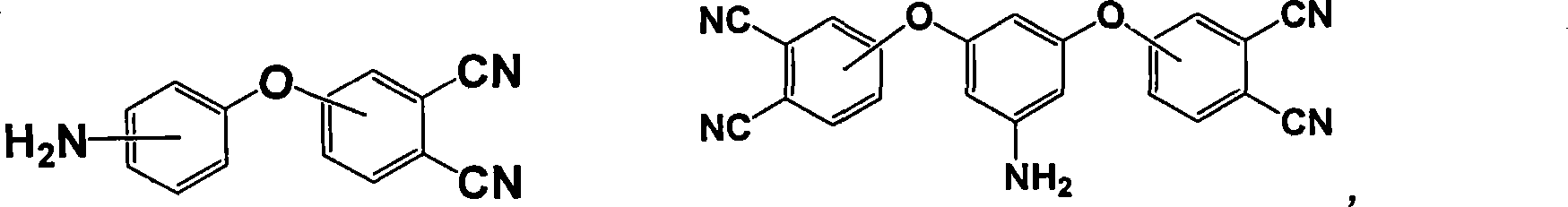

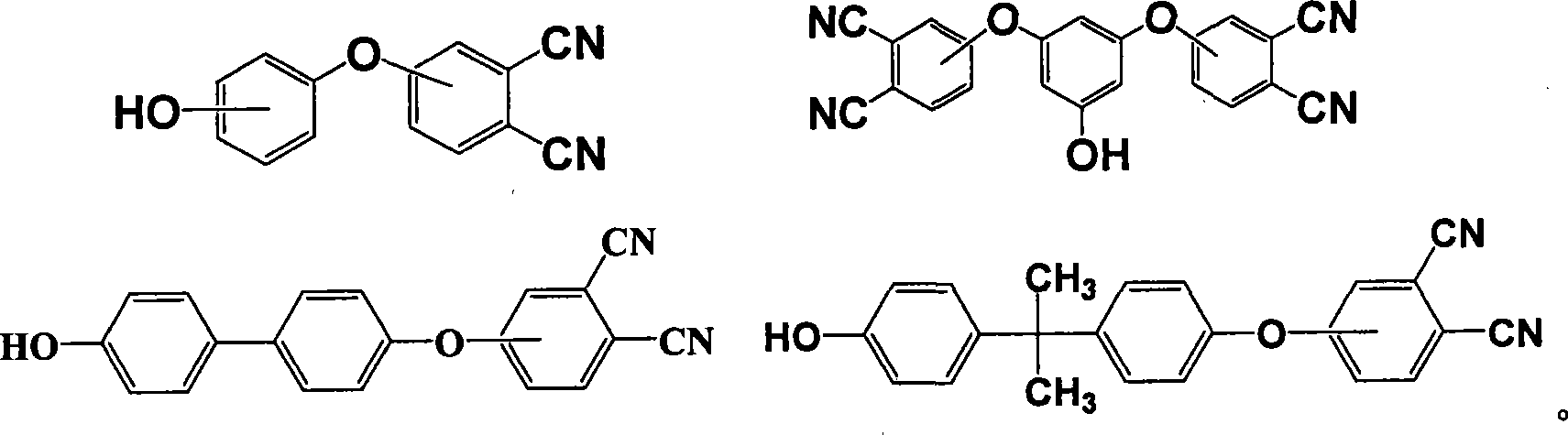

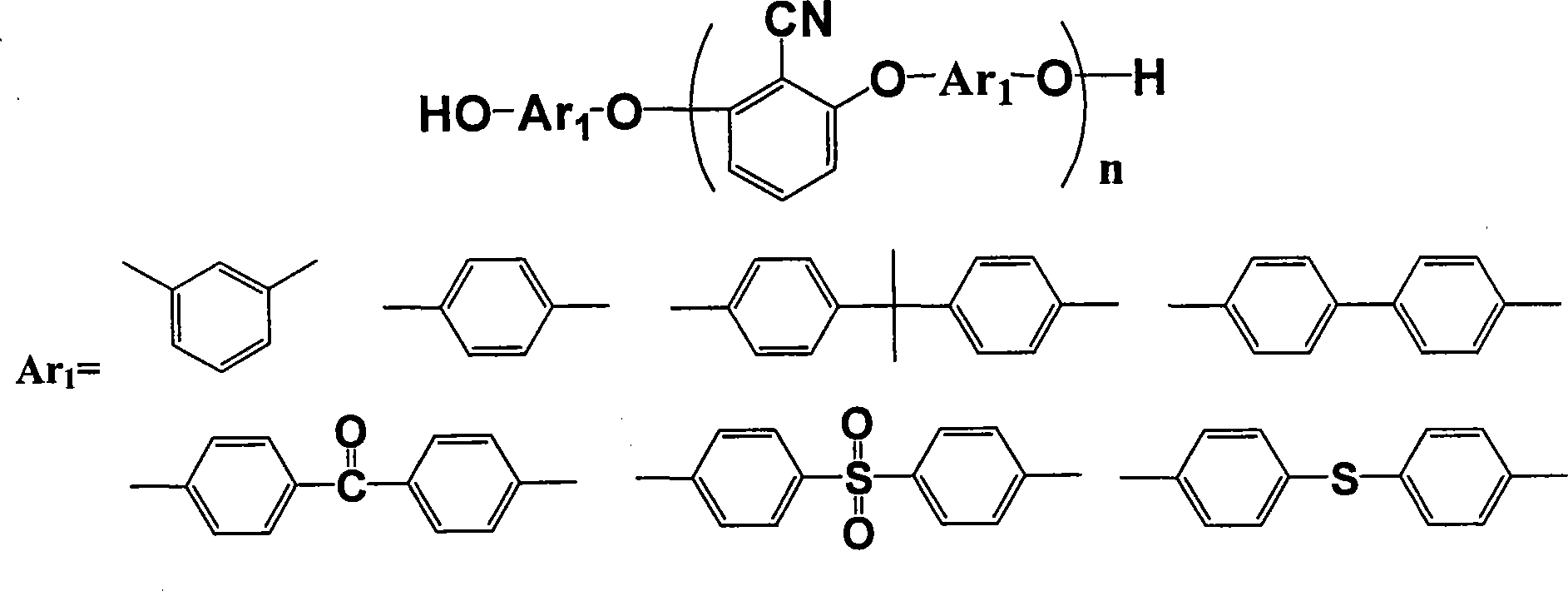

Poly-o-phthalonitrile resin and its preparing process

A polyphthalonitrile resin and a technology for polyphthalonitrile are applied in the field of polyphthalonitrile resin and its preparation, and can solve the problem of increasing the steps of resin processing, increasing the processing cost, and the amount of the two components of the resin. It is difficult to obtain changes, etc., to achieve the effect of suppressing volatility and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0131] Add 1 part of 4 / 3-(4-aminophenoxy)phthalonitrile and 99 parts of resorcinol-polyaryl ether nitrile into methanol to make them uniformly dispersed, heat up to 60°C and stir and mix, then reduce The mixture was obtained by removing the solvent under pressure; the mixture was solidified in turn according to the following procedures: heating at 200°C for 2 hours; heating at 260°C for 3 hours; heating at 325°C for 2 hours; heating at 350°C for 4 hours; heating at 375°C for 6 hours; hours.

Embodiment 2

[0133]Add 99 parts of 4 / 3-(2-aminophenoxy)phthalonitrile and 1 part of hydroquinone-polyaryl ether nitrile into N,N-dimethylformamide to dissolve it, and heat up After stirring and mixing at 20°C, remove the solvent under reduced pressure to obtain the mixture; solidify the mixture in turn according to the following procedures: heating at 200°C for 2 hours; heating at 260°C for 2 hours; heating at 325°C for 4 hours; heating at 350°C for 4 hours; heating at 375°C It can be heated for 8 hours.

Embodiment 3

[0135] Add 10 parts of 4 / 3-(3-aminophenoxy)phthalonitrile and 90 parts of 6F bisphthalonitrile into n-propanol to disperse them evenly, raise the temperature to 90°C, stir and mix, then reduce The mixture was obtained by removing the solvent under pressure; the mixture was solidified according to the following procedures: heating at 150°C for 4 hours; heating at 250°C for 2 hours; heating at 300°C for 4 hours; heating at 350°C for 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com