Glass fiber reinforced polypropylene composite material for car radiator grid and preparation process thereof

A technology for automobile radiators and composite materials, which is applied in the field of glass fiber reinforced polypropylene composite materials for automobile radiator grilles and its preparation technology, which can solve the problems of high prices, increased production costs, and failure to meet production needs. problems, achieve excellent heat resistance, improve rigidity and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

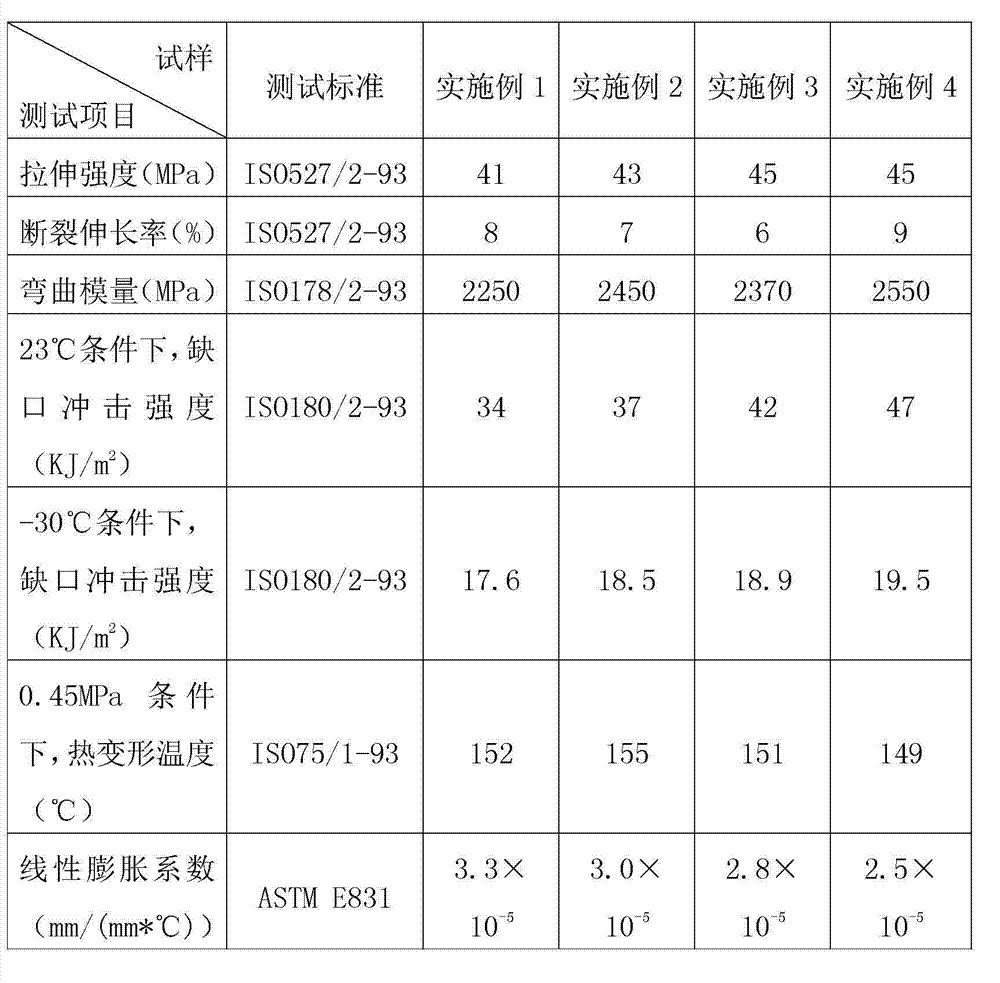

Examples

Embodiment 1

[0022] In this embodiment, the glass fiber reinforced polypropylene composite material for the automobile radiator grille is prepared as follows:

[0023] First, 69.8 parts of polypropylene PP SP179, 0.2 parts of phenolic heat stabilizer 1790, 0.3 parts of phosphite heat stabilizer 168, 0.3 parts of auxiliary EBS, 0.2 parts of hindered amine light stabilizer 770, 0.2 parts of nucleating agent TMP-5, 10 parts of ethylene-α-octene copolymer POE LC670, 4 parts of maleic anhydride grafted polypropylene CA-100 are put into a twin-screw extruder with a length-to-diameter ratio of 40:1 for melt mixing and dispersion;

[0024] Then 15 parts of alkali-free chopped glass fiber 305K was accurately added into the twin-screw extruder from the side feeding through a loss-in-weight metering scale; finally, it was extruded and pelletized by the twin-screw extruder at 200°C to obtain The glass fiber reinforced polypropylene composite material for the automobile radiator grille.

Embodiment 2

[0026] In this embodiment, the glass fiber reinforced polypropylene composite material for the automobile radiator grille is prepared as follows:

[0027] First, 63.5 parts of polypropylene PP K9017, 0.5 parts of phenolic heat stabilizer 1790, 0.5 parts of phosphite heat stabilizer 168, 0.5 parts of auxiliary EB-FF, 0.5 parts of hindered amine light stabilizer 944, 0.5 parts Core agent HPN-20E, 10 parts of ethylene-α-octene copolymer POE LC670, 4 parts of maleic anhydride grafted polypropylene 1001CN are put into a twin-screw extruder with a length-to-diameter ratio of 40:1 for melt mixing and dispersion;

[0028] Then 20 parts of alkali-free chopped glass fiber 508A is accurately fed into the twin-screw extruder through a loss-in-weight metering scale from the side feeding; finally, it is extruded and pelletized by the twin-screw extruder at 200°C to obtain The glass fiber reinforced polypropylene composite material for the automobile radiator grille.

Embodiment 3

[0030] In this embodiment, the glass fiber reinforced polypropylene composite material for the automobile radiator grille is prepared as follows:

[0031] First, 48 parts of polypropylene PP K9026, 1 part of phenolic heat stabilizer 1010, 1 part of phosphite heat stabilizer 627A, 1 part of auxiliary zinc stearate, 1 part of hindered amine light stabilizer 622, 1 part Nucleating agent HTPUTRA5, 15 parts of ethylene-α-octene copolymer POE 8130, and 7 parts of maleic anhydride grafted polypropylene 1001CN are put into a twin-screw extruder with a length-to-diameter ratio of 40:1 for melt mixing and dispersion;

[0032] Then 25 parts of alkali-free chopped glass fiber 508B is accurately added into the twin-screw extruder through a loss-in-weight metering scale from the side feeding; finally, it is extruded and pelletized by the twin-screw extruder at 200°C to obtain The glass fiber reinforced polypropylene composite material for the automobile radiator grille.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com