Polypropylene composite material and preparation method and application thereof

A technology for composite materials and polypropylene, which is applied in the field of polypropylene composite materials and its preparation, can solve the unsolved problems of low linear expansion coefficient, gloss and touch of polypropylene materials, and achieve low gloss, good touch and low linearity The effect of the coefficient of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

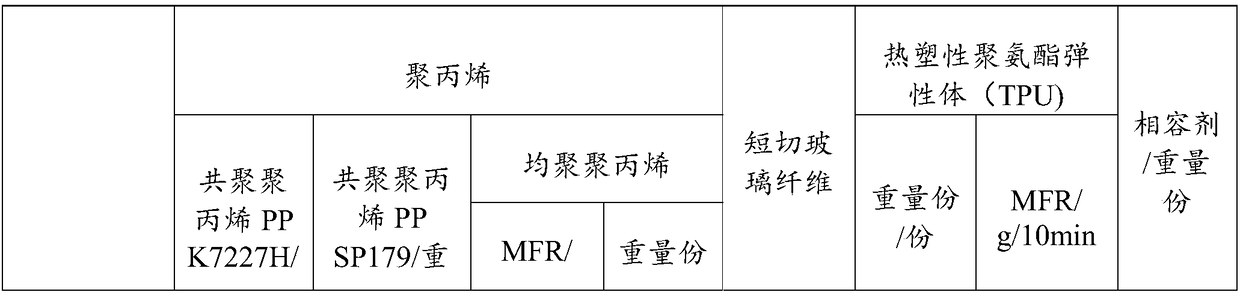

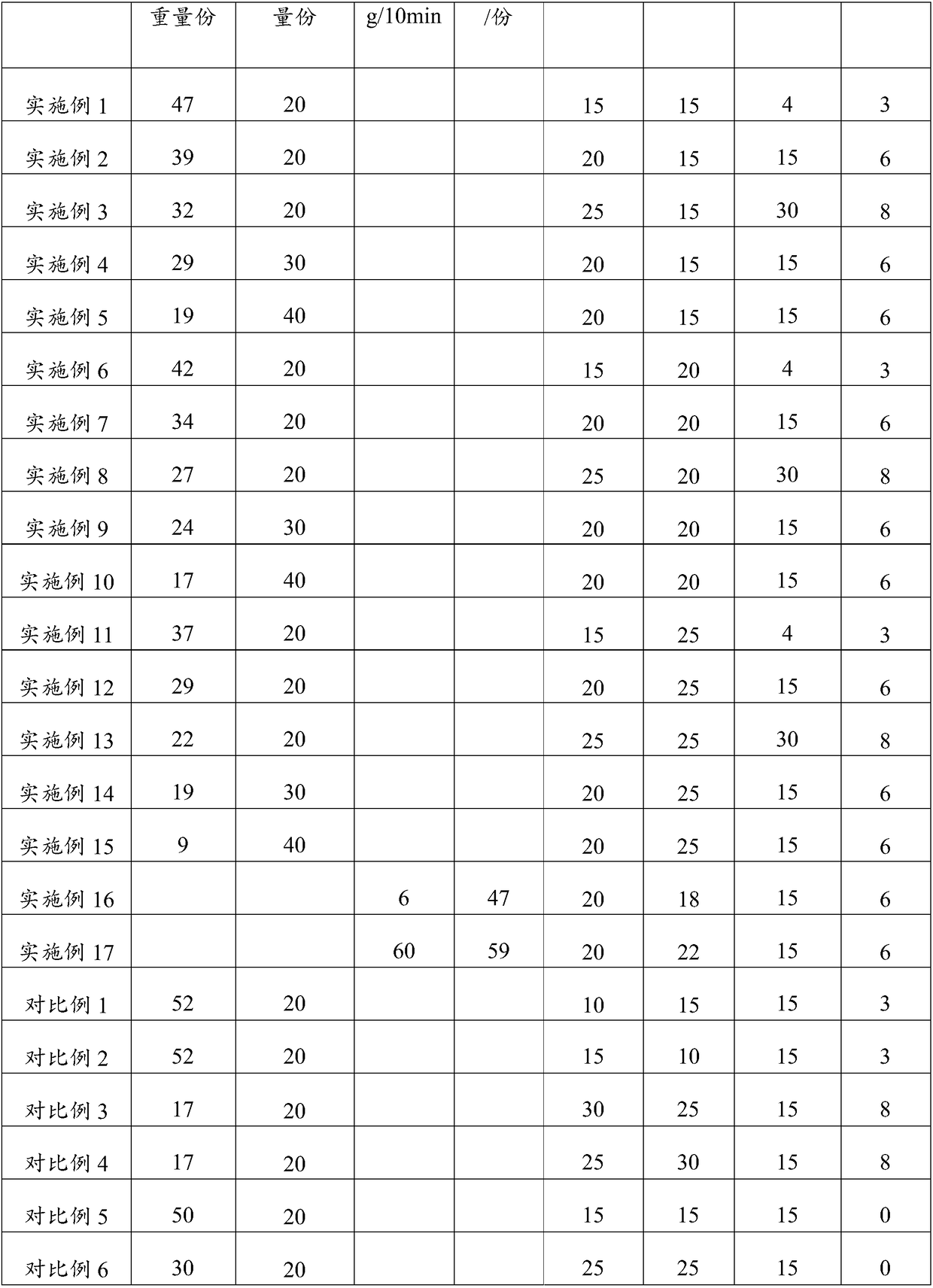

[0030] An embodiment of the polypropylene composite material of the present invention, the components of the polypropylene composite material in this embodiment are shown in Table 1.

[0031] The preparation method of polypropylene composite material described in this embodiment is:

[0032] (1) Put polypropylene, polyurethane, glass fiber and compatibilizer into a high-mixer according to the proportion and mix them thoroughly for 5 to 30 minutes, and mix evenly to obtain a mixture;

[0033] (2) Put the mixture obtained in step (1) into a twin-screw extruder with a length-to-diameter ratio of 40:1, melt, mix and disperse it, and then extrude and granulate to obtain a polypropylene composite material; wherein, each zone of the twin-screw extruder The temperature is 190-240° C., and the rotational speed of the twin-screw extruder is 300-800 rpm.

Embodiment 2~17 and comparative example 1~6

[0035] The composition components of the polypropylene composite materials described in Examples 2-17 and Comparative Examples 1-6 are all as shown in Table 1, and the preparation methods of the polypropylene composite materials described in Examples 2-17 and Comparative Examples 1-6 are all the same Example 1.

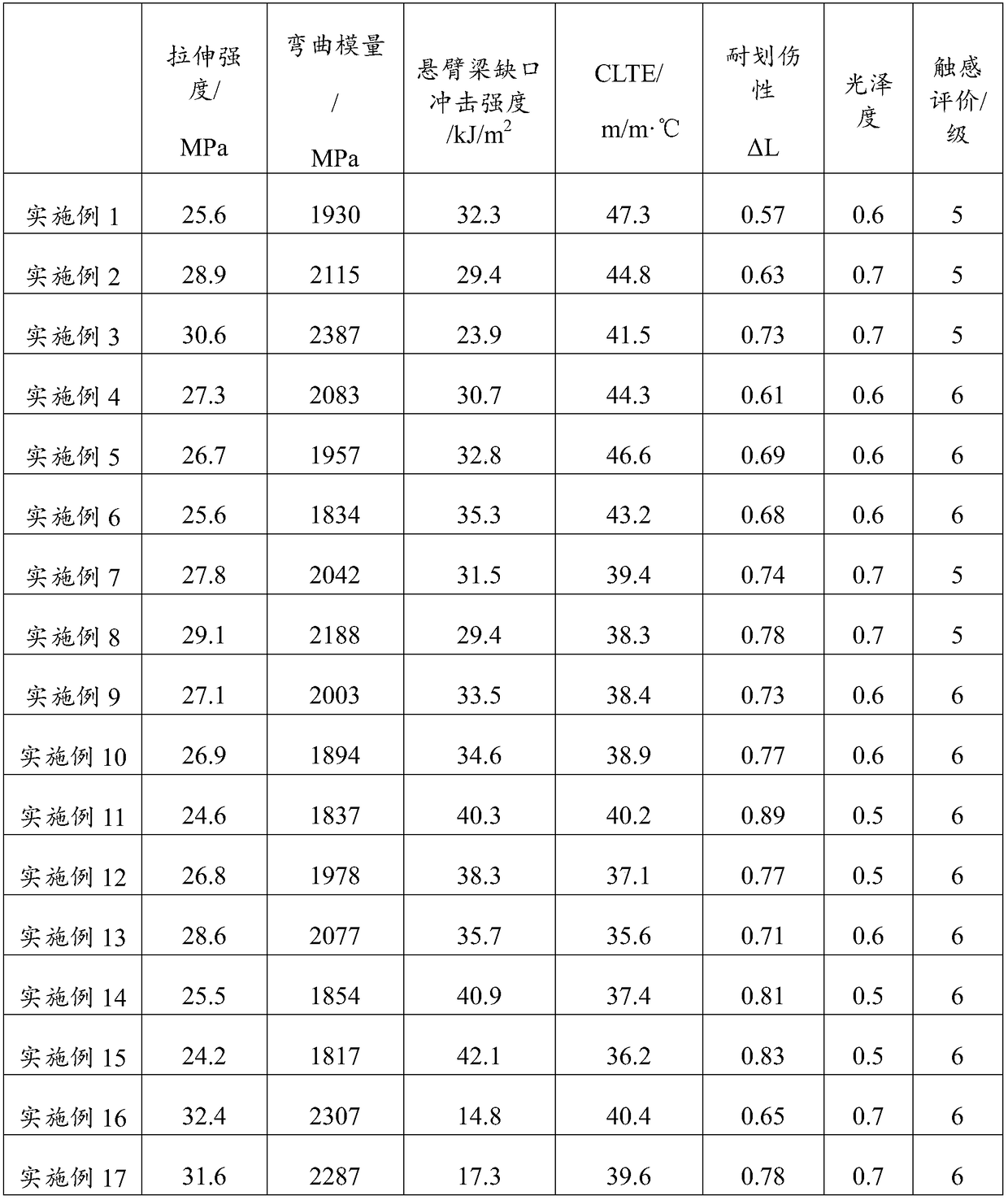

[0036] Simultaneously, test the following properties of the polypropylene composite material described in Examples 1 to 17 and Comparative Examples 1 to 6: tensile strength, flexural modulus, notched Izod impact strength, coefficient of linear expansion (CLTE), scratch resistance ( ΔL), gloss and touch. Among them, the test methods for each performance are:

[0037] The tensile strength test standard is ISO 527, and the test conditions are: tensile rate 50mm / min;

[0038] The flexural modulus test standard is ISO 178, and the test conditions are: bending rate 2mm / min, span 64mm;

[0039] The test standard for notched Izod impact strength is ISO 180, and the test co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com