PE160 grade composite material for pipes and preparation method of composite material

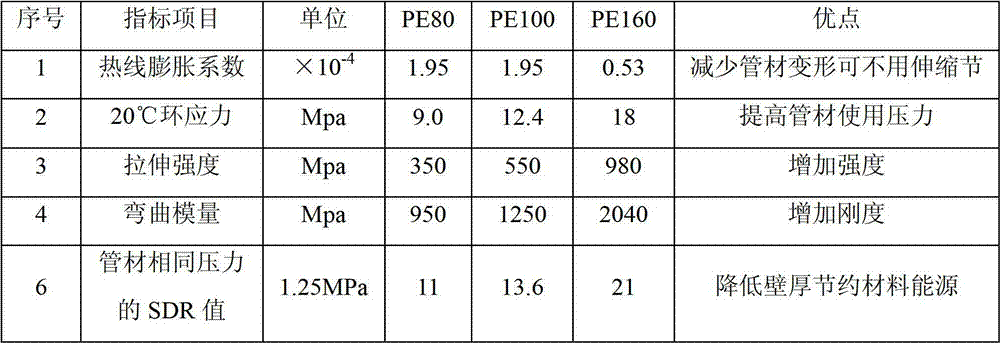

A 1. PE160, composite material technology, applied in the field of PE160 grade pipe composite material and its preparation, can solve the problems of poor mechanical properties of high-density polyethylene, restrict the application of HDPE, easy stress cracking, etc., to achieve strong impact resistance, Improve mechanical and thermal properties, reduce the effect of linear expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Composite material for PE160 grade pipes, which contains the following components, and the weight ratio of each component is:

[0048] HDPE resin 100,

[0049] Inorganic rigid particles 50,

[0050]Microfiber 30,

[0051] Functional raw materials8.

[0052] The inorganic rigid particles are calcium carbonate, talcum powder, wollastonite and kaolin with an average particle size of 0.5-10 μm.

[0053] The ultrafine fiber is nylon, vinylon, glass fiber, carbon fiber and aramid fiber with a diameter of 0.1-20 μm.

[0054] The functional raw materials are antioxidants, lubricants, coupling agents, solubilizers and inducers.

[0055] And the weight ratio of above-mentioned each component is:

[0056] HDPE resin 100,

[0059] wollastonite 15,

[0060] Kaolin 15,

[0061] Nylon 5,

[0062] Vinylon 10,

[0063] Fiberglass 4,

[0064] carbon fiber 4,

[0065] Aramid 7,

[0066] Antioxidant 1,

[0067] lubrica...

Embodiment 2

[0077] Composite material for PE160 grade pipes, which contains the following components, and the weight ratio of each component is:

[0078] HDPE resin 100,

[0079] Inorganic rigid particles 30,

[0080] Microfiber 40,

[0081] Functional ingredients 10.

[0082] The inorganic rigid particles are silicate, wollastonite, talcum powder, silicon dioxide and calcium carbonate with an average particle size of 0.5-10 μm and an average particle size of 1-1000 nm.

[0083] The ultrafine fibers are nylon and glass fibers with a diameter of 1-10 μm.

[0084] The functional raw materials are antioxidants, lubricants, coupling agents, toughening agents and solubilizers.

[0085] And the weight ratio of above-mentioned each component is:

[0086] HDPE resin 100,

[0087] calcium carbonate 5,

[0088] Talc 6,

[0089] Wollastonite 7,

[0090] Silica 6,

[0091] Silicate 6,

[0092] Nylon 20,

[0093] Fiberglass 20,

[0094] Antioxidant 4,

[0095] lubricant 6,

[0096] Coup...

Embodiment 3

[0105] Composite material for PE160 grade pipes, which contains the following components, and the weight ratio of each component is:

[0106] HDPE resin 100,

[0107] Inorganic rigid particles 0.5,

[0108] Microfiber 1,

[0109] Functional ingredients 0.05.

[0110] The inorganic rigid particles are calcium carbonate with an average particle size of 0.5-10 μm.

[0111] The ultrafine fibers are glass fibers with a diameter of 0.1-3 μm.

[0112] The functional raw material is a coupling agent.

[0113] And the weight ratio of above-mentioned each component is:

[0114] HDPE resin 100,

[0115] Calcium carbonate 0.5,

[0116] Fiberglass 1,

[0117] Coupling agent 0.05,

[0118] It includes the following steps:

[0119] A, select the raw materials in the above formula except ultrafine fibers, prepare and weigh according to the proportion and put them into the high mixer and stir for 3 minutes;

[0120] B. Put the homogeneously mixed material in step A into the barrel o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com