Ultralow-linear expansion coefficient polypropylene composite material and preparation method thereof

A linear expansion coefficient, composite material technology, applied in the field of polypropylene, can solve the problems of shrinkage rate change, material performance loss, density increase, etc., to achieve the effect of simple operation and easy guarantee of material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

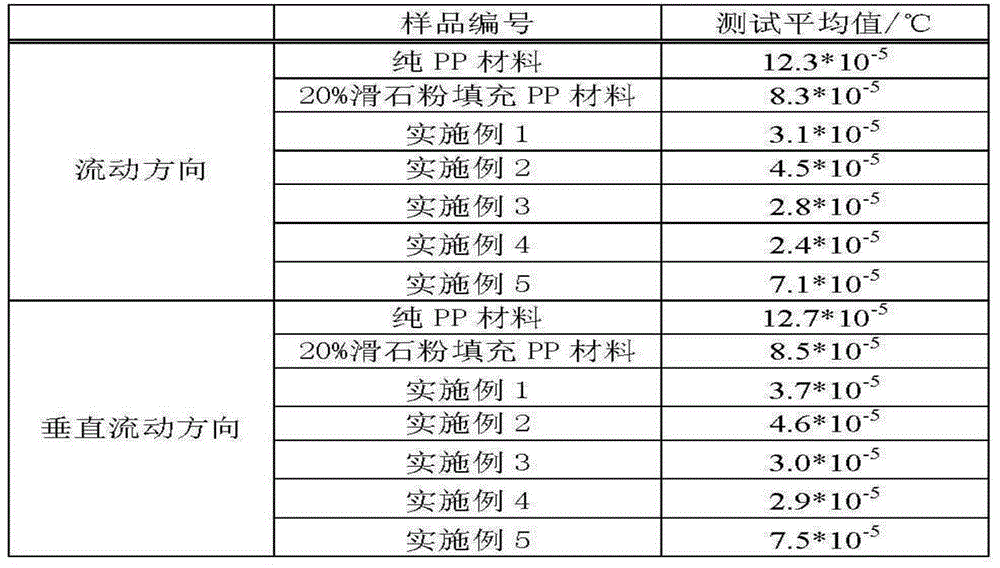

Examples

Embodiment 1

[0032] Mix 95 kg polypropylene, 0.5 kg phenolic heat stabilizer 1010, 0.5 kg lubricant EBS, 5 kg Sc 2 W 3 o 12 , 0.2 kg of titanate coupling agent NDZ109, 0.2 kg of white oil 36# are melted, mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1. After all raw materials are blended and extruded to granulate, the implementation Examples of polypropylene composites. The processing temperature during preparation was 200°C.

Embodiment 2

[0034] 97 kg of polypropylene, 0.5 kg of phenolic heat stabilizer 1010, 0.5 kg of lubricant zinc stearate, 0.3 kg of lubricant calcium stearate, 3 kg of Sc 2 W 3 o 12 , 0.4 kilograms of silane coupling agent KH-550, and 0.3 kilograms of white oil 32# are melted and mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 56:1. After all raw materials are blended and extruded to granulate, the implementation Examples of polypropylene composites. The processing temperature during preparation was 220°C.

Embodiment 3

[0036] With 93 kilograms of polypropylene, 0.1 kilogram of phenolic heat stabilizer 1010 and 0.1 kilogram of heat stabilizer 168, 0.2 kilogram of silane coupling agent KH-570, 0.2 kilogram of white oil 15#, 7 kilograms of Sc 2 W 3 o 12 Melt, mix and disperse in a twin-screw extruder with an aspect ratio of 35:1. After all raw materials are blended, extruded and granulated, the polypropylene compound of this example is obtained. The processing temperature during preparation was 170°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com