Stress whitening resistant low-VOC (Volatile Organic Compounds) low-linear-expansion-coefficient polypropylene material

A low linear expansion, anti-stress whitening technology, applied in the field of modified polypropylene materials, can solve the problems of unguaranteed material odor, unsatisfactory mechanical properties, inapplicability, etc., to improve the anti-bending stress whitening performance, The effect of reducing linear expansion coefficient and odor, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

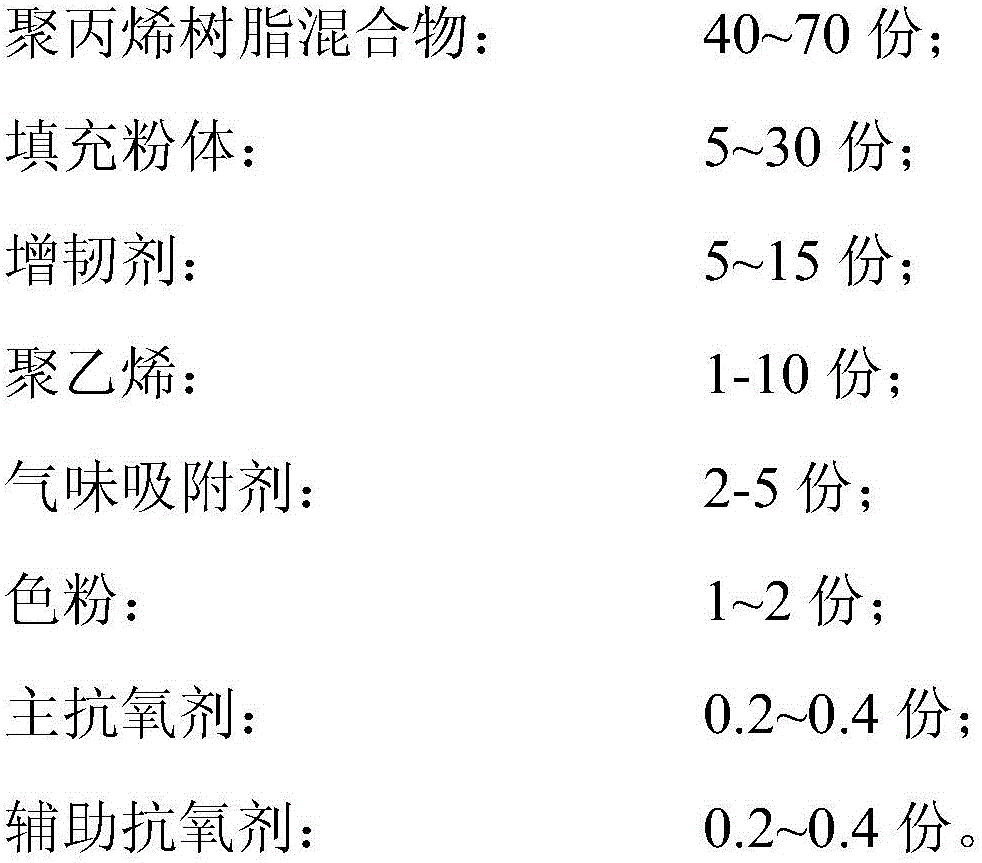

Method used

Image

Examples

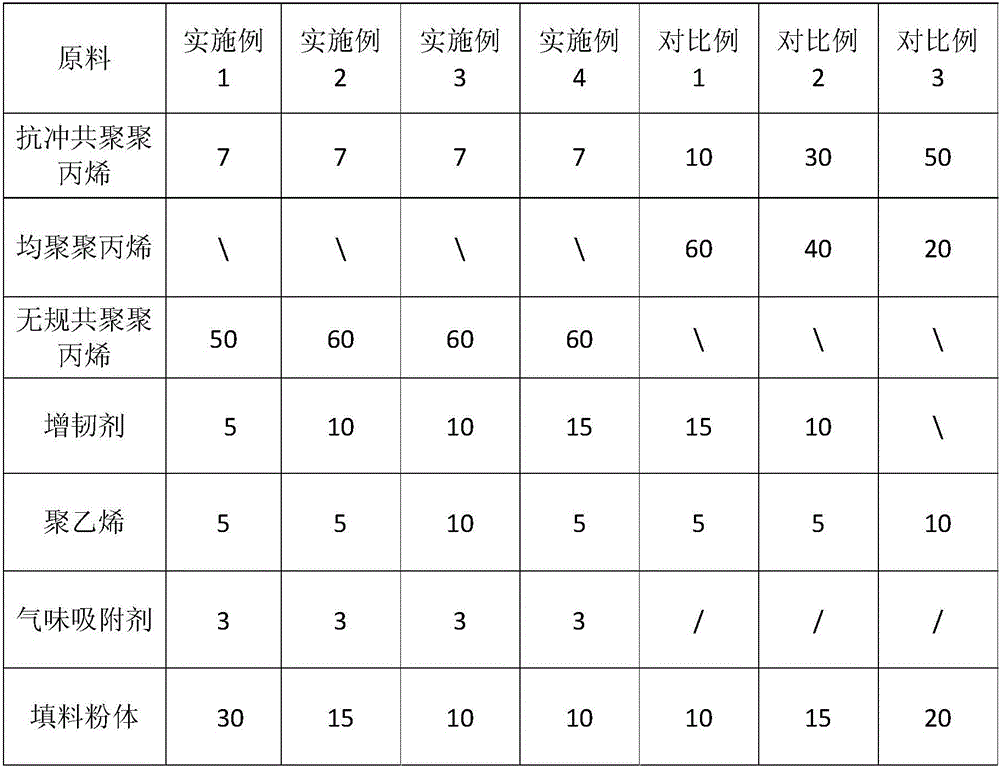

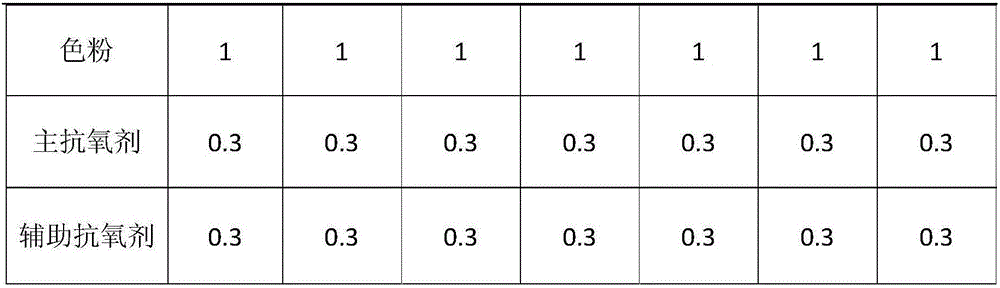

Embodiment 1

[0032] Weigh the components according to the following parts by weight: 10.0 parts of impact copolymerized polypropylene, 50.0 parts of random copolymerized polypropylene, 5 parts of ethylene-octene copolymer, 5.0 parts of high density polyethylene, 30 parts of talcum powder, diatom 3.0 parts of soil, 1.0 parts of toner, 0.3 parts of antioxidant 1010, 0.3 parts of antioxidant 168, each component was placed in a high-speed mixer and fully stirred to obtain a premix, and the premix was added to the twin-screw extruder The main feeding port of the machine is melt-extruded, granulated and dried to obtain a stress-whitening-resistant, low-VOC, low-linear-expansion-coefficient polypropylene material, an anti-stress-whitening, low-VOC, low-linear-expansion-coefficient polypropylene material.

[0033] The melt extrusion conditions of the twin-screw extruder are: the temperature of the first zone is 80-120°C, the temperature of the second zone is 190-210°C, the temperature of the third ...

Embodiment 2

[0035] Weigh the components according to the following parts by weight: 10.0 parts of impact copolymerized polypropylene, 60.0 parts of random copolymerized polypropylene, 15.0 parts of ethylene-octene copolymer, 5.0 parts of high-density polyethylene, 15.0 parts of talcum powder, diatom 3.0 parts of soil, 1.0 parts of toner, 0.3 parts of antioxidant 1010, 0.3 parts of antioxidant 168, each component was placed in a high-speed mixer and fully stirred to obtain a premix, and the premix was added to the twin-screw extruder The main feeding port of the machine is melt-extruded, granulated and dried to obtain a stress-whitening-resistant, low-VOC, low-linear-expansion-coefficient polypropylene material, an anti-stress-whitening, low-VOC, low-linear-expansion-coefficient polypropylene material.

[0036] The melt extrusion conditions of the twin-screw extruder are: the temperature of the first zone is 80-120°C, the temperature of the second zone is 190-210°C, the temperature of the t...

Embodiment 3

[0038] The components were weighed according to the following parts by weight: 10.0 parts of impact copolymerized polypropylene, 60.0 parts of random copolymerized polypropylene, 13.0 parts of ethylene-octene copolymer, 5.0 parts of high-density polyethylene, 20.0 parts of talcum powder, diatom 3.0 parts of soil, 1.0 parts of toner, 0.3 parts of antioxidant 1010, 0.3 parts of antioxidant 168, each component was placed in a high-speed mixer and fully stirred to obtain a premix, and the premix was added to the twin-screw extruder The main feeding port of the machine is melt-extruded, granulated and dried to obtain a stress-whitening-resistant, low-VOC, low-linear-expansion-coefficient polypropylene material, an anti-stress-whitening, low-VOC, low-linear-expansion-coefficient polypropylene material.

[0039]The melt extrusion conditions of the twin-screw extruder are: the temperature of the first zone is 80-120°C, the temperature of the second zone is 190-210°C, the temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com