Polytetrafluoroethylene fiber

A polytetrafluoroethylene and fiber technology, applied in the field of polytetrafluoroethylene fibers, can solve the problems of affecting the chemical properties of materials, large linear expansion coefficient, poor thermal conductivity, etc., to improve dimensional stability, increase hardness, and reduce linear expansion coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

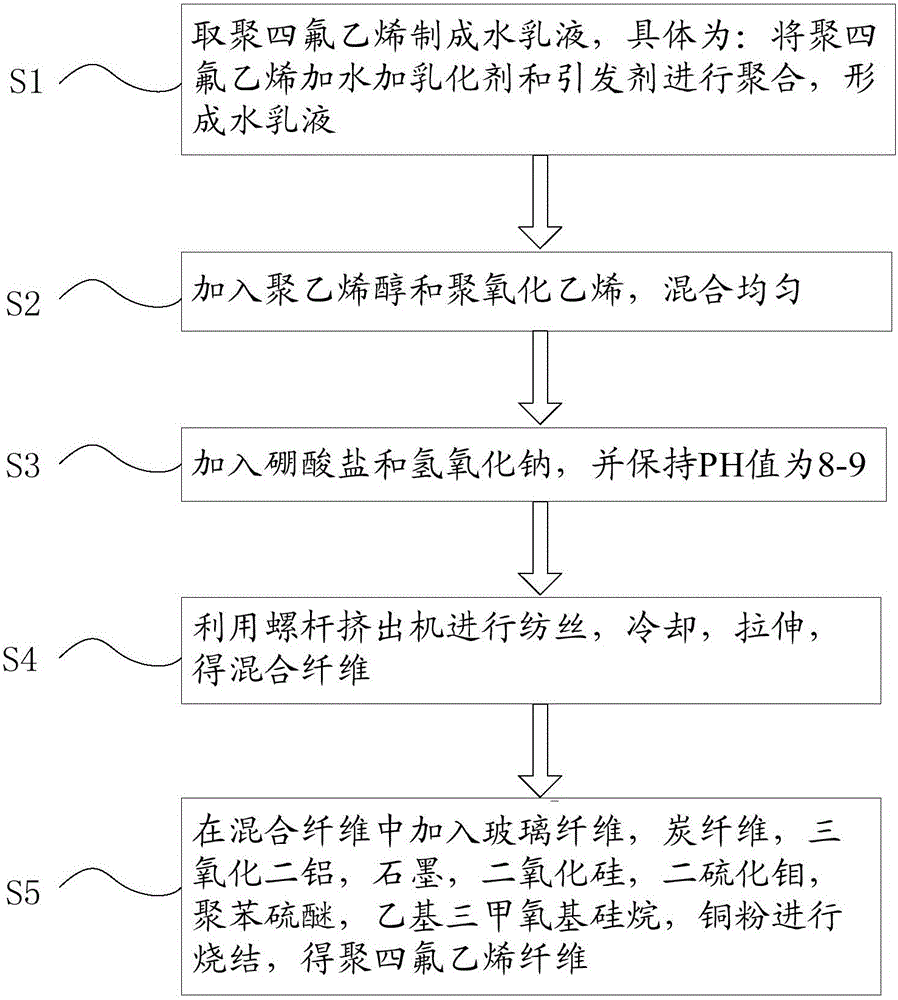

Method used

Image

Examples

Embodiment 1

[0012] This embodiment provides polytetrafluoroethylene fiber, including the following components by weight:

[0013] 85 parts of polytetrafluoroethylene, 17 parts of glass fiber, 24 parts of carbon fiber, 5 parts of aluminum oxide, 18 parts of graphite, 11 parts of silicon dioxide, 5 parts of molybdenum disulfide, 9 parts of polyphenylene sulfide, ethyl trimethyl 7 parts of oxysilane and 4 parts of copper powder.

Embodiment 2

[0015] This embodiment provides polytetrafluoroethylene fiber, including the following components by weight:

[0016] 90 parts of polytetrafluoroethylene, 20 parts of glass fiber, 20 parts of carbon fiber, 6 parts of aluminum oxide, 16 parts of graphite, 8 parts of silicon dioxide, 5 parts of molybdenum disulfide, 8 parts of polyphenylene sulfide, ethyl trimethyl 6 parts of oxysilane and 4 parts of copper powder.

Embodiment 3

[0018] This embodiment provides polytetrafluoroethylene fiber, including the following components by weight:

[0019] 88 parts of polytetrafluoroethylene, 18 parts of glass fiber, 23 parts of carbon fiber, 4 parts of aluminum oxide, 17 parts of graphite, 10 parts of silicon dioxide, 4 parts of molybdenum disulfide, 8.5 parts of polyphenylene sulfide, ethyl trimethyl 7.5 parts of oxysilane and 5 parts of copper powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| coefficient of linear thermal expansion | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com