Nitrogen, boron co-doped carbon quantum dots coated nickel-cobalt-aluminate lithium battery cathode material and preparation method

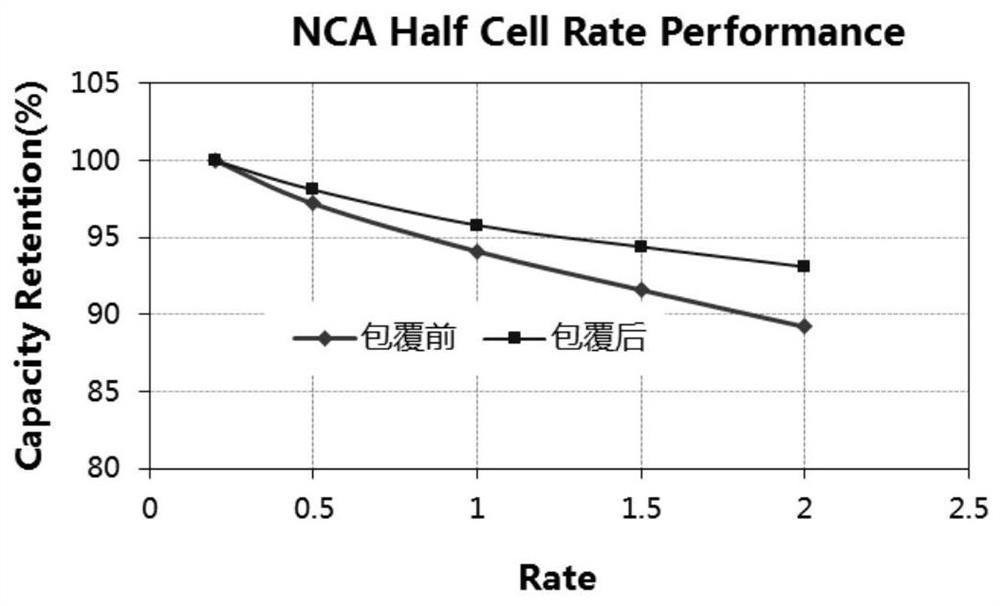

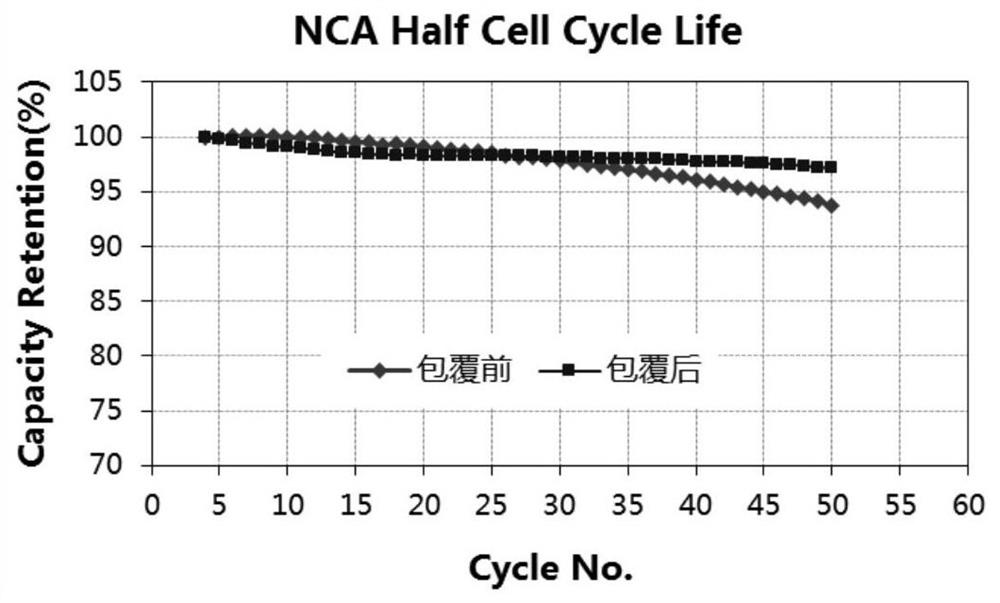

A technology of nickel cobalt lithium aluminate and carbon quantum dots, used in battery electrodes, circuits, electrical components, etc., can solve the problem of not being able to have rate performance and structural stability at the same time, and achieve reduced irreversible capacity, good safety performance, and reduced The effect of the degree of volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] In this embodiment, the preparation method of the nitrogen and boron co-doped carbon quantum dots coated nickel-cobalt lithium aluminate battery positive electrode material, the method includes:

[0019] Step S1. Weigh citric acid monohydrate into a beaker, add ultrapure water to completely dissolve it to obtain a citric acid solution, then add a boron source and a nitrogen-containing compound to the citric acid solution, and disperse evenly by ultrasonic to obtain a uniformly mixed aqueous solution .

[0020] In this step, the concentration of the citric acid solution is 0.5-2g / mL, and the addition amount of the boron element in the boron source and the nitrogen element in the nitrogen-containing compound is 0.5-3% of the molar weight of the citric acid. The compound is one or more of urea, ammonia water, and ethylenediamine, and the boron source may be boric acid.

[0021] Step S2, reacting the aqueous solution in an oven for a period of time, then taking it out and ...

Embodiment 1

[0029] 1) Accurately weigh 50g of citric acid monohydrate in a beaker, add 50mL of ultrapure water to dissolve it completely, the final concentration of citric acid solution is 1g / mL, then add 2.9g of boric acid and 1.43g of ethylenediamine, and ultrasonicate for 30min to make the above The material is fully dispersed and uniform, and then placed in an oven with a heating rate of 10°C / min and thermally cracked at 200°C for 2.5 hours. After the reaction, naturally cool to room temperature to obtain a nitrogen and boron co-doped carbon quantum dot solution. 1g of the product was dissolved in 20mL of water with ultrapure water by means of ultrasound to form a nitrogen and boron co-doped carbon quantum dot solution;

[0030] 2) Mix lithium hydroxide and nickel cobalt aluminum hydroxide precursors in a high-speed mixer according to the lithium / metal molar ratio of 1.01, then place them in an atmosphere furnace and sinter at 790°C for 12 hours in an oxygen atmosphere, and naturally c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com