Isotropic polypropylene composition with low linear expansion coefficient and preparation method thereof

A technology of polypropylene composition and low linear expansion, which is applied in the field of modified plastics, and can solve the problems of material warping, large linear expansion coefficient of polypropylene, and large difference in linear expansion coefficient of polypropylene materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

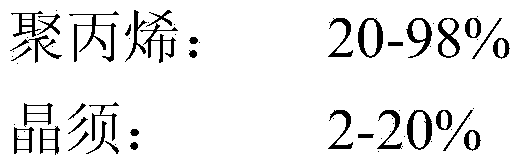

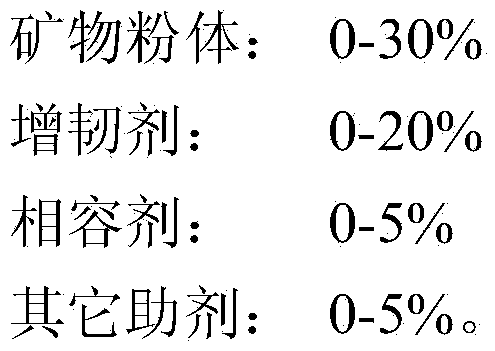

Method used

Image

Examples

Embodiment 1-5

[0041] A preparation method of an isotropic low linear expansion coefficient polypropylene composition, comprising the following steps:

[0042] Weigh the raw materials according to the formula of mass percentage in Table 3, put polypropylene, mineral powder, toughening agent, compatibilizer and other additives into a high-speed mixer with a rotation speed of 1000rpm and mix for 3 minutes, then from the twin-screw The main feeding port of the extruder enters the twin-screw extruder for melt blending, and the whisker powder is fed from the side 1 / 3 to 2 / 3 of the length of the screw extruder from the main feeding port. After feeding into the twin-screw extruder, melt blending with the components fed from the main feeding port, the temperature is controlled at 200-240°C, the screw speed is 450 rpm, and polypropylene is obtained after extrusion and granulation combination;

[0043] The resulting polypropylene composition was prepared according to the ISO standard, and the transve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com