Polypropylene composition with good dimensional stability and preparation method and application thereof

A technology of polypropylene composition and dimensional stability, which is applied in the field of modified plastics, can solve the problems of large differences in linear expansion coefficients, etc., and achieve the effect of improving dimensional stability and improving dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

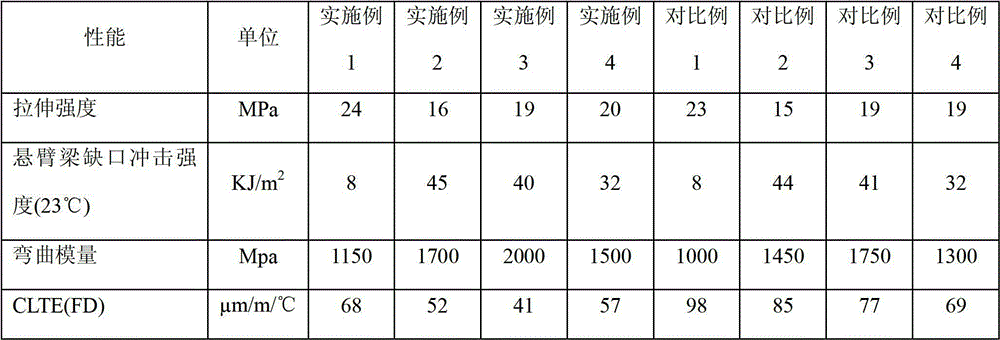

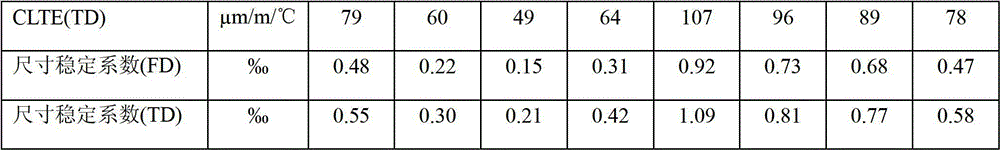

Examples

Embodiment 1

[0031] A polypropylene composition with good dimensional stability, its raw material formulation is shown in Table 1, and its preparation method comprises the following steps:

[0032] Adding polypropylene, elastomer, mineral filler, inorganic filler, nucleating agent and other additives into a twin-screw extruder, performing melt blending, extruding and granulating to obtain the polypropylene composition with good dimensional stability ; The aspect ratio of the twin-screw extruder is (32-48):1, and the processing temperature of the twin-screw extruder is 180-250°C.

[0033] The polypropylene used is high crystalline polypropylene with an isotacticity ≥ 99%, crystallinity ≥ 70%, and a melt flow rate of 3-70g / 10min under the conditions of 230°C and 2.16kg.

[0034] The elastomer used is an ethylene-propylene-diene copolymer.

[0035] The nucleating agent used was sodium 2,2'-methylene-bis(4,6-di-tert-butylphenoxy)phosphate.

[0036] The mineral filler used is ultra-fine high-...

Embodiment 2

[0040] A polypropylene composition with good dimensional stability, its raw material formula is shown in Table 1, and its preparation method is the same as in Example 1.

[0041] Used polypropylene, mineral filler, inorganic filler, other additives are all with embodiment 1.

[0042] The elastomer used is an ethylene-butene copolymer.

[0043] The nucleating agent used was sodium bis(4-tert-butyl-phenoxy)phosphate.

Embodiment 3

[0045] A polypropylene composition with good dimensional stability, its raw material formula is shown in Table 1, and its preparation method is the same as in Example 1.

[0046] Used polypropylene, mineral filler, inorganic filler, other additives are all with embodiment 1.

[0047] The elastomers used are ethylene-propylene-diene copolymers and ethylene-octene copolymers.

[0048] The nucleating agents used were 2,2'-methylene-bis(4,6-di-tert-butylphenoxy)sodium phosphate and bis[2,2'-methylene-bis(4,6-bis tert-butylphenoxy) hydroxyaluminum phosphate].

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com