Resin composition for electronic component encapsulation and electronic component device

A technology of resin composition and electronic components, which is applied in the direction of electrical components, electrical solid devices, semiconductor/solid device parts, etc., can solve the problems of package warpage and achieve the effect of warpage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

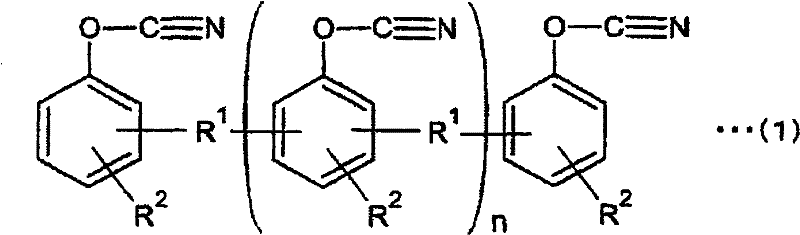

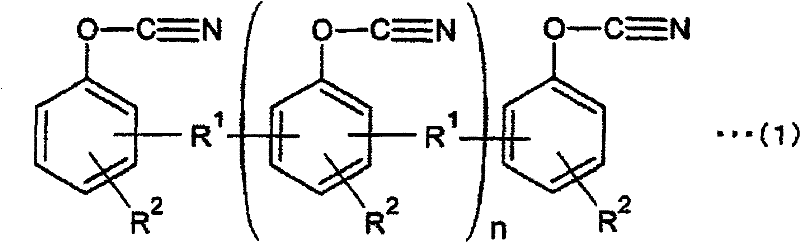

Image

Examples

Embodiment 1~4, comparative example 1 and 2

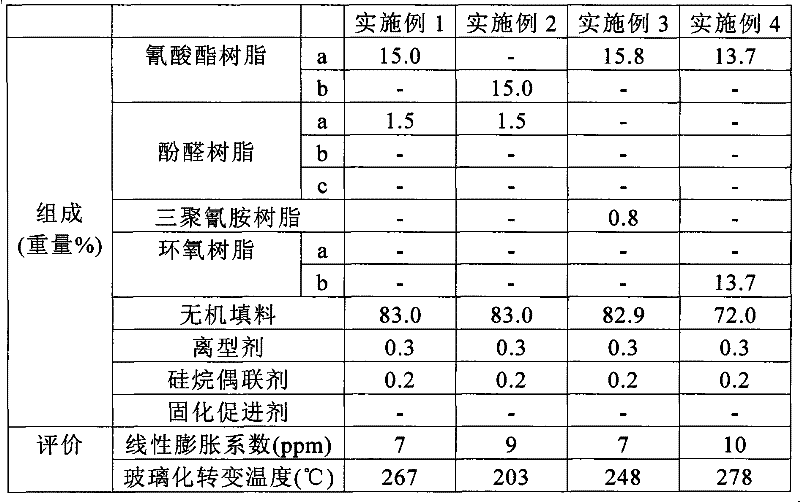

[0065] Various ingredients shown in Tables 1 and 2 below were blended in the ratios shown in the tables, and melt-kneaded at 100°C for 3 minutes using a roller kneader. Then, the molten product was cooled and then pulverized to prepare a resin composition.

[0066] [Linear expansion coefficient, glass transition temperature]

[0067] Using the obtained resin composition, a cured product (length: 20 mm, width: 3 mm, thickness: 3 mm) was prepared by transfer molding (175° C.×3 minutes). The obtained cured product was subjected to post-curing (175° C.×5 hours, then 200° C.×4 hours, and finally 250° C.×4 hours) to prepare test pieces. The linear expansion coefficient and the glass transition temperature were determined using a TMA apparatus (model MG800GM) manufactured by Rigaku Corporation at a temperature increase rate of 5° C. / min. Tables 1 and 2 show the results.

[0068] Table 1

[0069]

[0070] Table 2

[0071]

[0072] The coefficient of linear expansion of a ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com