Glass fiber, surface treatment method of glass fiber, plastic and shell

A glass fiber and surface treatment technology, applied in the field of materials, can solve the problem of weak bonding ability between glass fiber and ABS plastic, and achieve the effect of reducing the linear expansion coefficient and improving the bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

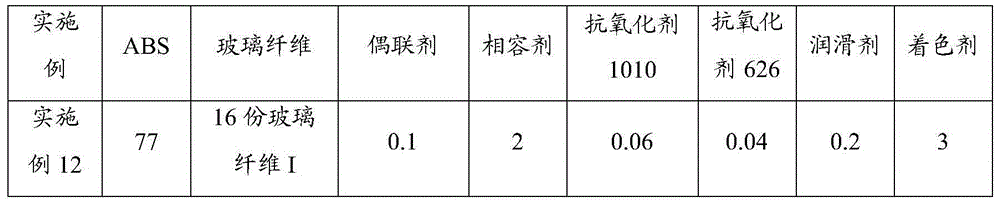

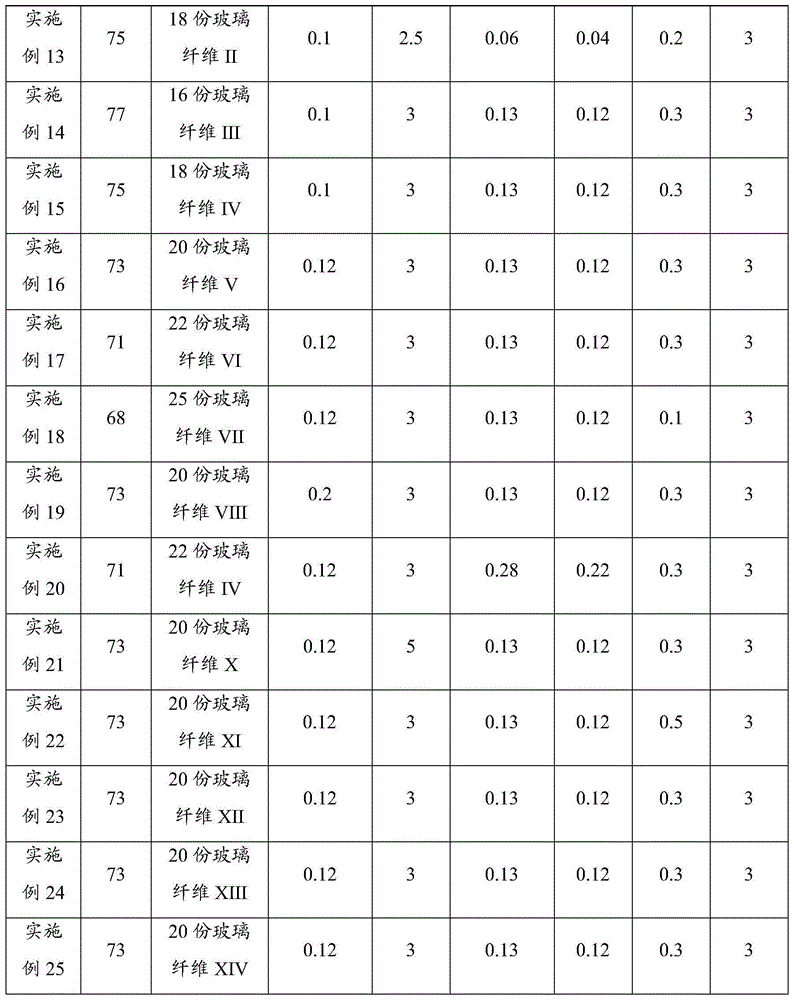

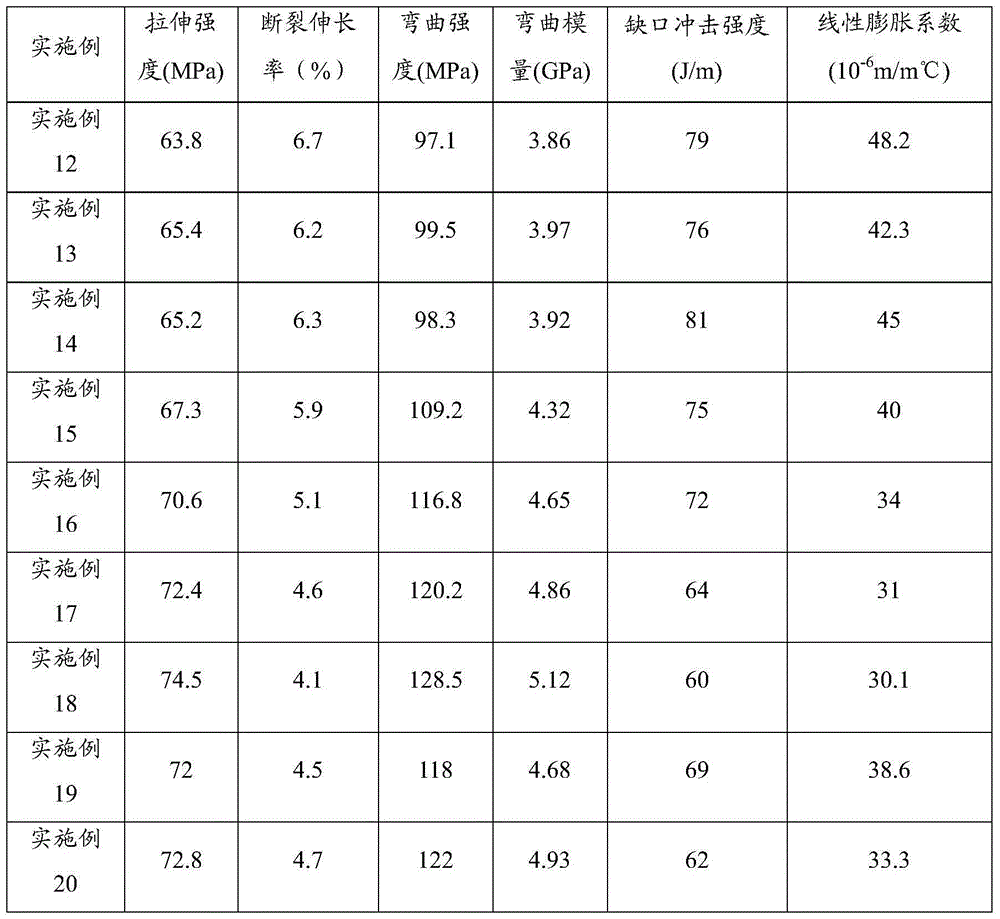

Examples

Embodiment 1

[0045] The glass fiber to be treated (flatness 1.5, length 3mm) is corroded in an corrosive solution for 30 seconds, wherein the corrosive solution includes a corrosion inhibitor with a mass fraction of 0.05%, and a mass fraction of 99.95% An acidic aqueous solution, the acidic aqueous solution of this embodiment is composed of the following components: 10 parts by weight of hydrofluoric acid with a concentration of 2% to 3% and 1 part by weight of hydrochloric acid with a concentration of 0.5% to 1%;

[0046] The corroded glass fiber is soaked in a coupling agent, and the coupling agent in this embodiment is vinyltriethoxysilane;

[0047] The glass fibers after soaking treatment are dried, and heating can be used to remove water on the surface of the glass fibers (subsequent examples are all dried by heating), to obtain surface-treated glass fibers I.

Embodiment 2

[0049] The glass fiber to be treated (flatness 3, length 5mm) is corroded in the corrosive solution for 35 seconds, wherein the corrosive solution includes a corrosion inhibitor with a mass fraction of 0.1%, and a mass fraction of 99% Acidic aqueous solution, the acidic aqueous solution of this embodiment is made up of following composition: the concentration of 10 parts by weight is the hydrofluoric acid of 2%~3% and the concentration of 2 parts by weight is the nitric acid of 0.5%~1%;

[0050] The corroded glass fiber is soaked in a coupling agent, and the coupling agent in this embodiment is γ-aminopropyltriethoxysilane (KH550);

[0051] Drying the soaked glass fibers to obtain surface-treated glass fibers II.

Embodiment 3

[0053] The glass fiber to be treated (flatness 4, length 7mm) is corroded in the corrosive solution for 30 seconds, wherein the corrosive solution includes a corrosion inhibitor with a mass fraction of 0.05%, and a mass fraction of 99.5% An acidic aqueous solution, the acidic aqueous solution of this embodiment is composed of the following components: 10 parts by weight of hydrofluoric acid with a concentration of 2% to 3% and 1 part by weight of hydrochloric acid with a concentration of 0.5% to 1%;

[0054] The corroded glass fiber is soaked in a coupling agent, and the coupling agent in this embodiment is vinyltriethoxysilane;

[0055] Drying the impregnated glass fibers to obtain surface-treated glass fibers III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com