Reinforced and toughened polyformaldehyde and preparation method thereof

A technology of strengthening and toughening polyoxymethylene, applied in the field of strengthening and toughening polyoxymethylene and its preparation, can solve the problems of increasing the impact toughness of POM, weakening the toughening effect, and reducing the mechanical strength, so as to improve the overall performance and enhance the interface interaction , the effect of large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

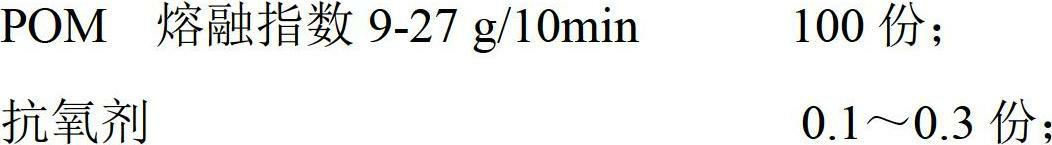

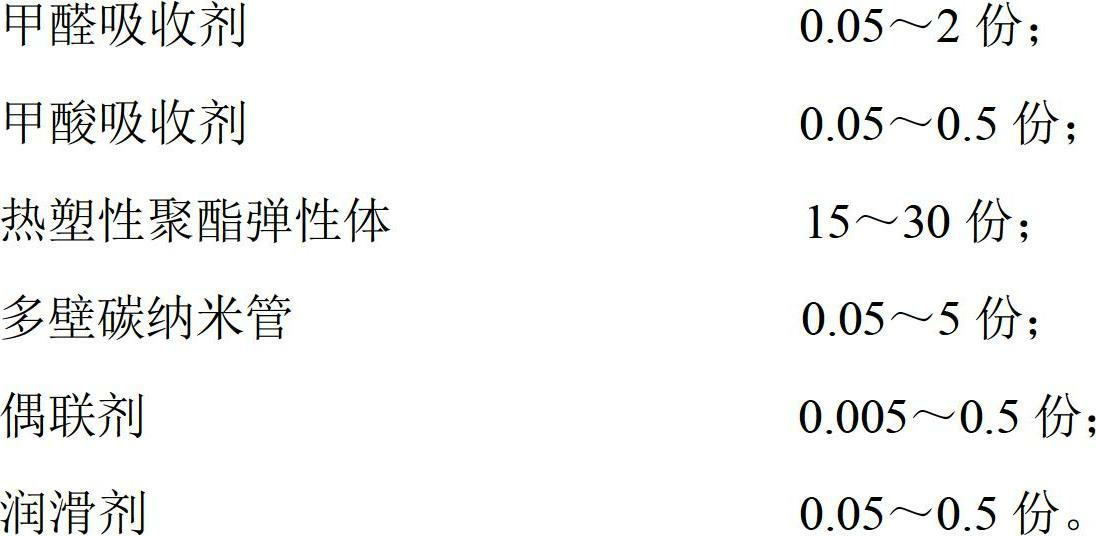

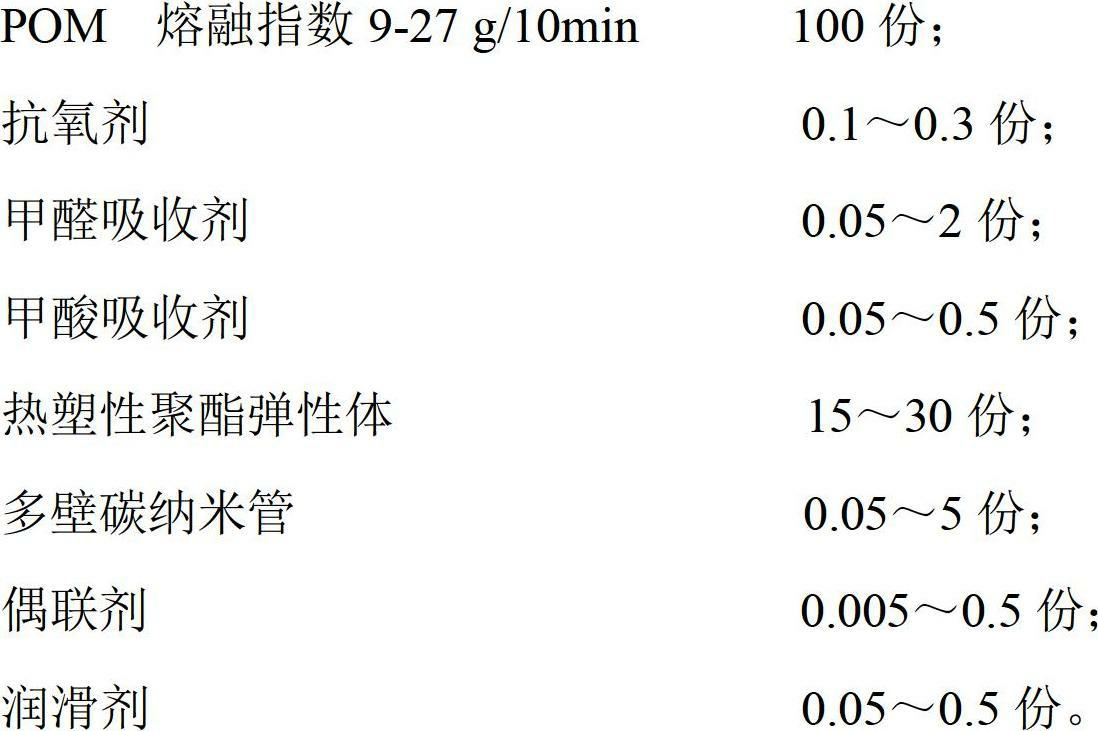

[0026] Example 1 Preparation of reinforced and toughened polyoxymethylene

[0027] Mix 10Kg of POM resin with 30g of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 20g of melamine, 20g of calcium carbonate, 2Kg of thermoplastic polyester elastomer, surface treatment hydroxylation Add 100 g of multi-walled carbon nanotubes and 10 g of glycerol monostearate into a high-speed mixer for mixing, then melt and knead with a vented twin-screw extruder, extrude and granulate, and obtain reinforced and toughened polyoxymethylene, wherein, The screw speed is 50 rpm; the temperature of each section of the barrel is 140-200°C. The notched impact strength of this product can reach 18KJ / m 2 Around, and maintain a high tensile strength, up to 41MPa.

Embodiment 2

[0028] Example 2 Preparation of reinforced and toughened polyoxymethylene

[0029] Mix 10Kg of POM resin with 40g of N,N'-bis-[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hexamethylenediamine, 10g of dicyandiamide, 10g of magnesium oxide, thermoplastic polymer Add 3Kg of ester elastomer, 200g of surface-treated carboxylated multi-walled carbon nanotubes, and 20g of bisstearamide into a high-speed mixer for mixing, then melt and knead with a vented twin-screw extruder, extrude and granulate, and then strengthen Toughened polyoxymethylene, wherein, the screw speed is 150 rpm; the temperature of each section of the barrel is 160-220°C. The notched impact strength of this product can reach 25KJ / m 2 Around, and maintain a high tensile strength, up to 45MPa.

Embodiment 3

[0030] Example 3 Preparation of reinforced and toughened polyoxymethylene

[0031] Mix 10Kg of POM resin with 10g of β-(4-hydroxy-3,5-di-tert-butylphenyl) octadecyl propionate, 70g of urea, 7g of calcium silicate, 2.5Kg of thermoplastic polyester elastomer, surface treated hydroxyl 400g of multi-walled carbon nanotubes and 30g of pentaerythritol tristearate are added in a high-speed mixer and mixed, then melted and mixed with a vented twin-screw extruder, extruded and granulated, to obtain reinforced and toughened polyoxymethylene, wherein , Screw speed, 100 rpm; barrel temperature, 170 ~ 210 ℃. The notched impact strength of this product can reach 18KJ / m 2 Around, and maintain a high tensile strength, up to 42MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com