Preparation method of high-temperature-resistant oxidation-resistant heat-conducting carbon fiber/silicon carbide composite material

A composite material and carbon fiber technology, which is applied in the field of preparation of high-temperature, oxidation-resistant, thermally conductive carbon fiber/silicon carbide composite materials, can solve problems such as low thermal conductivity and weak interaction, and achieve enhanced thermal conductivity, simple method, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

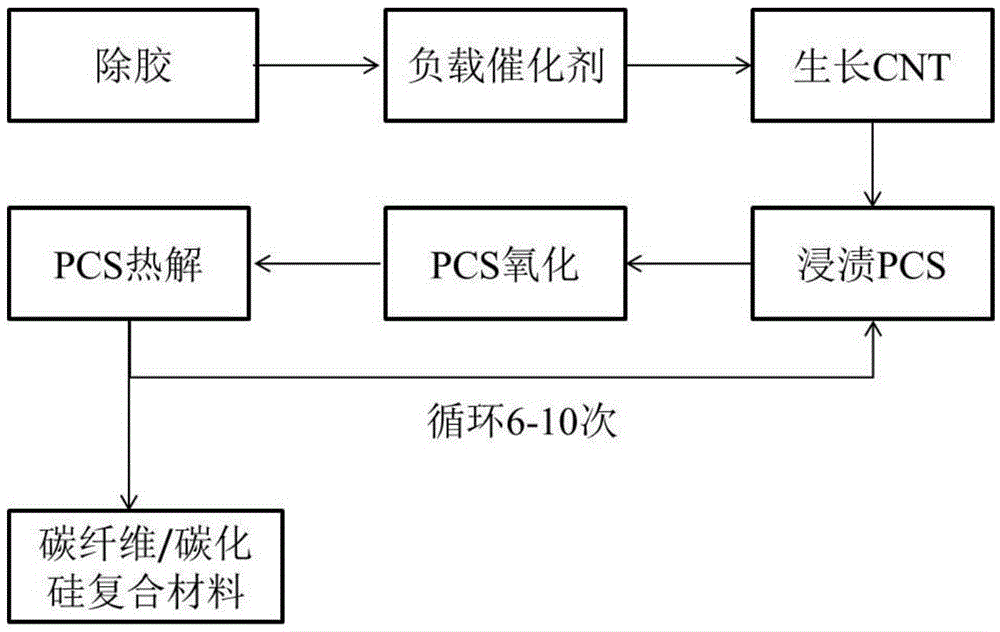

Method used

Image

Examples

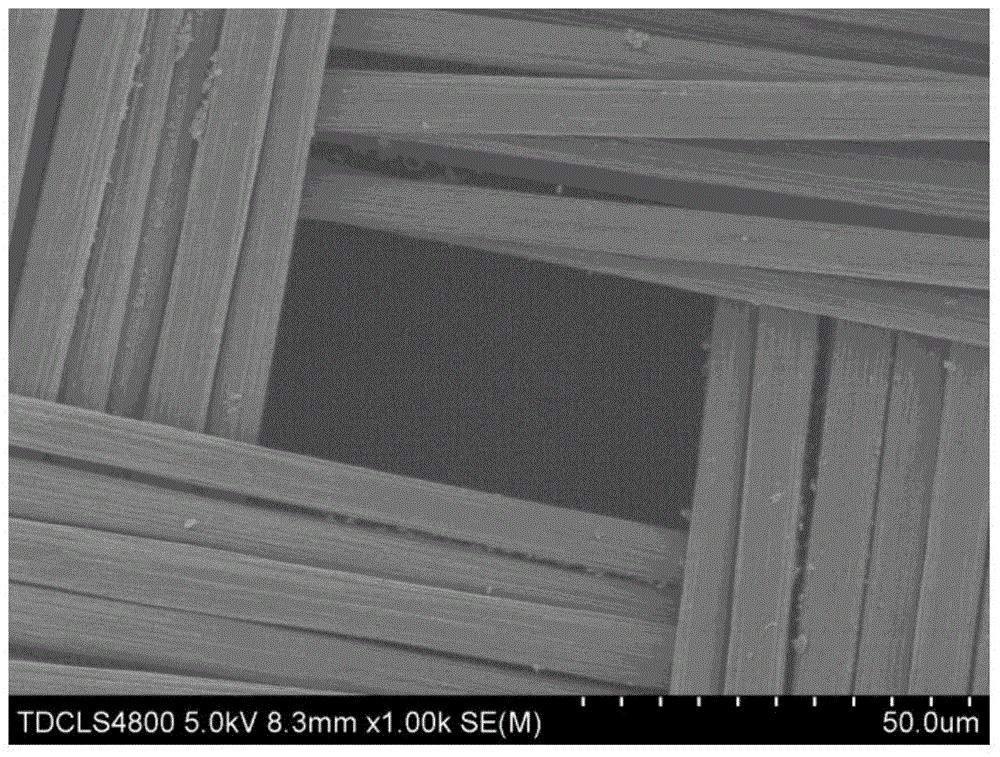

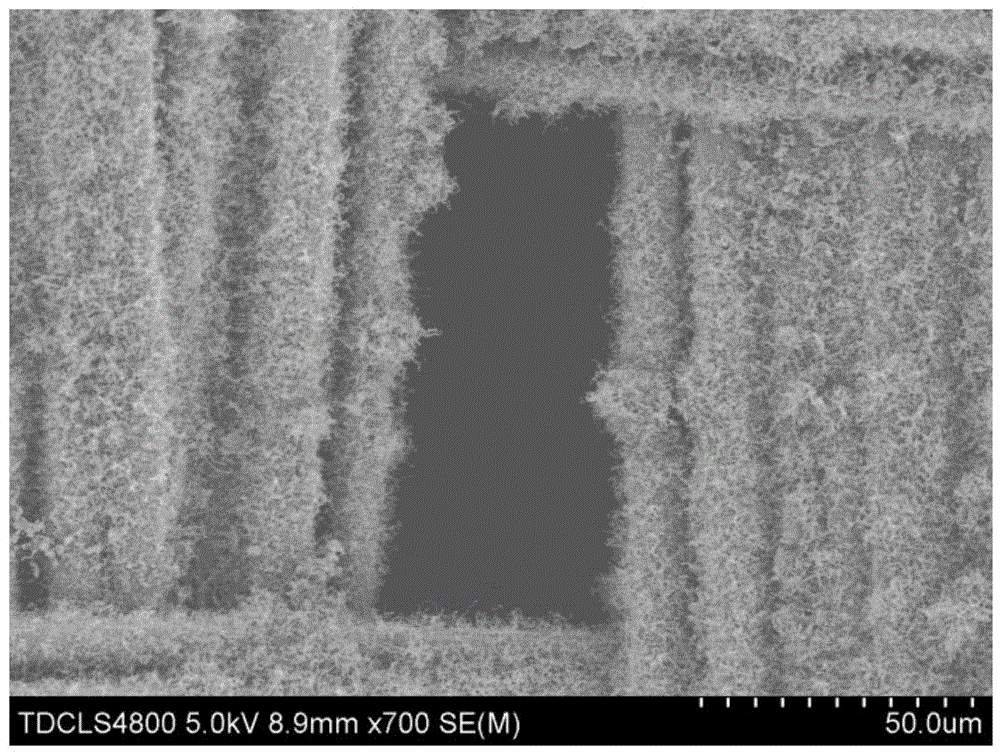

Embodiment 1

[0032] After cleaning and drying the carbon fiber fabric, it is placed in a tube furnace, heated to 700°C at a rate of 5°C / min under Ar atmosphere, and kept at a constant temperature for 0.5h to remove the polymer coating on the surface of the carbon fiber fabric when it leaves the factory. Soak the degummed carbon fiber cloth in Fe(NO 3 ) 3 In solution. After soaking for 0.5h, take it out and dry it. The catalyst-supporting carbon fiber is woven and arranged in a tube furnace. Ar was introduced (flow rate is 200sccm), and the temperature was raised to 400°C at a rate of 5°C / min. Reduce Ar flow to 100sccm and pass H at the same time 2 (The flow rate is 200sccm). After 10min, increase the Ar flow to 350sccm and reduce H 2 The flow rate is 20sccm. The temperature is increased to 750°C at a rate of 5°C / min. A carbon source (ethanol:xylene=1:1) was introduced, the injection speed was 20ml / h, and the growth time was 10min. Close H after growth is over 2 Reduce the Ar flow rate ...

Embodiment 2

[0034] After cleaning and drying the carbon fiber fabric, it is placed in a tube furnace, heated to 750°C at a rate of 10°C / min under Ar atmosphere, and kept at a constant temperature for 1 hour to remove the polymer coating on the surface of the carbon fiber fabric when it leaves the factory. Soak the degummed carbon fiber cloth in Fe(NO 3 ) 3 In solution. After soaking for 1h, take it out and dry it. The catalyst-supporting carbon fiber is woven and arranged in a tube furnace. Ar was introduced (flow rate is 300sccm), and the temperature was increased to 450°C at a rate of 10°C / min. Reduce Ar flow rate to 150sccm while passing H 2 (The flow rate is 250sccm). After 20min, increase Ar flow to 380sccm and decrease H 2 The flow rate is 35sccm. The temperature is increased to 800°C at a rate of 10°C / min. A carbon source (ethanol:xylene=1:1) was introduced, the injection speed was 20ml / h, and the growth time was 30min. Close H after growth is over 2 Reduce the Ar flow rate to ...

Embodiment 3

[0036] After cleaning and drying the carbon fiber fabric, it is placed in a tube furnace, heated to 800°C at a rate of 15°C / min under Ar atmosphere, and kept at a constant temperature for 2 hours to remove the polymer coating on the surface of the carbon fiber fabric when it leaves the factory. Soak the degummed carbon fiber cloth in Fe(NO 3 ) 3 In solution. After soaking for 2h, take it out and dry it. The catalyst-supporting carbon fiber is woven and arranged in a tube furnace. Ar was introduced (flow rate is 400sccm), and the temperature was raised to 500°C at a rate of 15°C / min. Reduce Ar flow to 200sccm and pass H at the same time 2 (The flow rate is 300sccm). After 30min, increase Ar flow to 400sccm and decrease H 2 The flow rate is 50sccm. The temperature is increased to 850°C at a rate of 15°C / min. A carbon source (ethanol:xylene=1:1) was introduced, the injection speed was 20ml / h, and the growth time was 60min. Close H after growth is over 2 Reduce the Ar flow rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com