Aramid III fiber reinforced self-lubricating gasket composite material and preparation method thereof

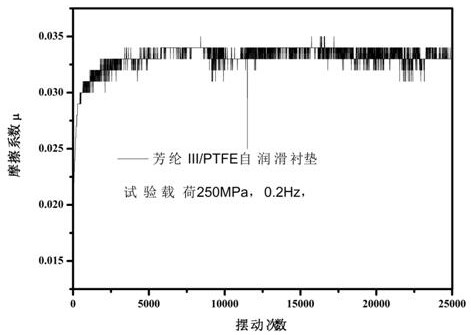

A liner material and self-lubricating technology, applied in the aramid III fiber reinforced self-lubricating liner composite material and its preparation, in the field of fiber-reinforced self-lubricating liner composite material, can solve the problem that the interface reinforcement cannot be achieved, and the fiber- Resin matrix, modification damage and other problems, to achieve the effect of improving mechanical properties and friction and wear properties, slowing down the generation and expansion of micro-cracks, excellent bearing capacity and wear life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) 200D aramid III fiber and PTFE fiber are plied and twisted on the fiber twisting equipment to obtain a twisted yarn with a twist of 160 twists / meter;

[0027] (2) Prepare polyester size, add antioxidant, antistatic agent and other components to it, and carry out sizing treatment on aramid III fiber;

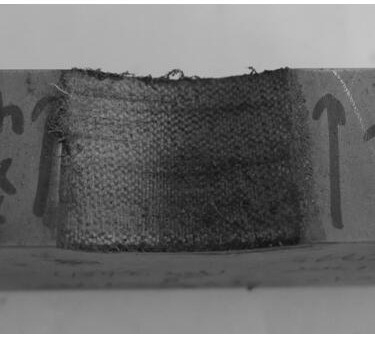

[0028] (3) Sizing aramid III fibers are used as warp yarns, and twisted yarns of aramid fibers III and PTFE fibers are used as weft yarns, and are woven on a loom, and the gray fabric is a plain weave; the fabric after being off the machine is desized to obtain aramid fibers III / PTFE fabric gray cloth;

[0029] (4) Immerse the aramid III / PTFE fabric gray cloth in the aqueous solution of tannic acid (1mg / ml)-aminopropyltriethoxysilane (1mg / ml) and react at room temperature for 6 hours to obtain surface-activated aramid fiber III / PTFE fabric gray cloth;

[0030] (5) The activated aramid III / PTFE fabric gray cloth was immersed in the MgAl-LDH precursor solution (0.012m...

Embodiment 2

[0034] (1), (2), (3), (4) are the same as embodiment 1;

[0035] (5) The activated aramid III / PTFE fabric gray cloth was immersed in the MgAl-LDH precursor solution (0.009molMg(NO 3 ) 2 ·6H 2 O and 0.003mol Al(NO 3 ) 3 9H 2 O added to 120ml deionized water), pressurized reaction at 120°C for 24h, after the reaction, wash the fabric gray cloth with deionized water, and dry at 80°C; soak the dried aramid III / PTFE fabric gray cloth into dopamine-polyethylene Imine buffer solution (1.5mg / ml), react at room temperature for 6h, take out and wash with deionized water, dry at 80°C, and then immerse in ANFs dimethyl sulfoxide solution (0.002g / ml), react at room temperature for 1h, take out Rinse with dimethyl sulfoxide for 2 minutes, rinse with deionized water for 3 times, and dry at 80°C to obtain aramid III / PTFE fabric gray fabric with strong-tough integrated interface modification;

[0036] (6) Repeatedly soak the modified aramid III / PTFE fabric gray cloth in the phenolic resi...

Embodiment 3

[0039] (1), (2), (3), (4) are the same as embodiment 1;

[0040] (5) The activated aramid III / PTFE fabric gray cloth was immersed in the MgAl-LDH precursor solution (0.006molMg(NO 3 ) 2 ·6H 2 O and 0.002mol Al(NO 3 ) 3 9H 2 O added to 120ml deionized water), pressurized reaction at 120°C for 24h, after the reaction, wash the fabric gray cloth with deionized water, and dry at 80°C; soak the dried aramid III / PTFE fabric gray cloth into dopamine-polyethylene Imine buffer solution (2mg / ml), react at room temperature for 6h, take it out and wash it with deionized water, dry it at 80°C and immerse it in ANFs dimethyl sulfoxide solution (0.0015g / ml), react at room temperature for 1h, take it out for Rinse with dimethyl sulfoxide for 2 minutes, rinse with deionized water for 3 times, and dry at 80°C to obtain aramid III / PTFE fabric gray fabric with integrated strong-tough interface modification;

[0041] (6) Repeatedly soak the modified III / PTFE fabric gray cloth in the phenolic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com