Polymer-silicon dioxide coated carbon nanotube composite material, preparation method thereof, prepreg and copper-clad substrate

A carbon nanotube, silicon dioxide technology, used in chemical instruments and methods, electronic equipment, other household appliances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

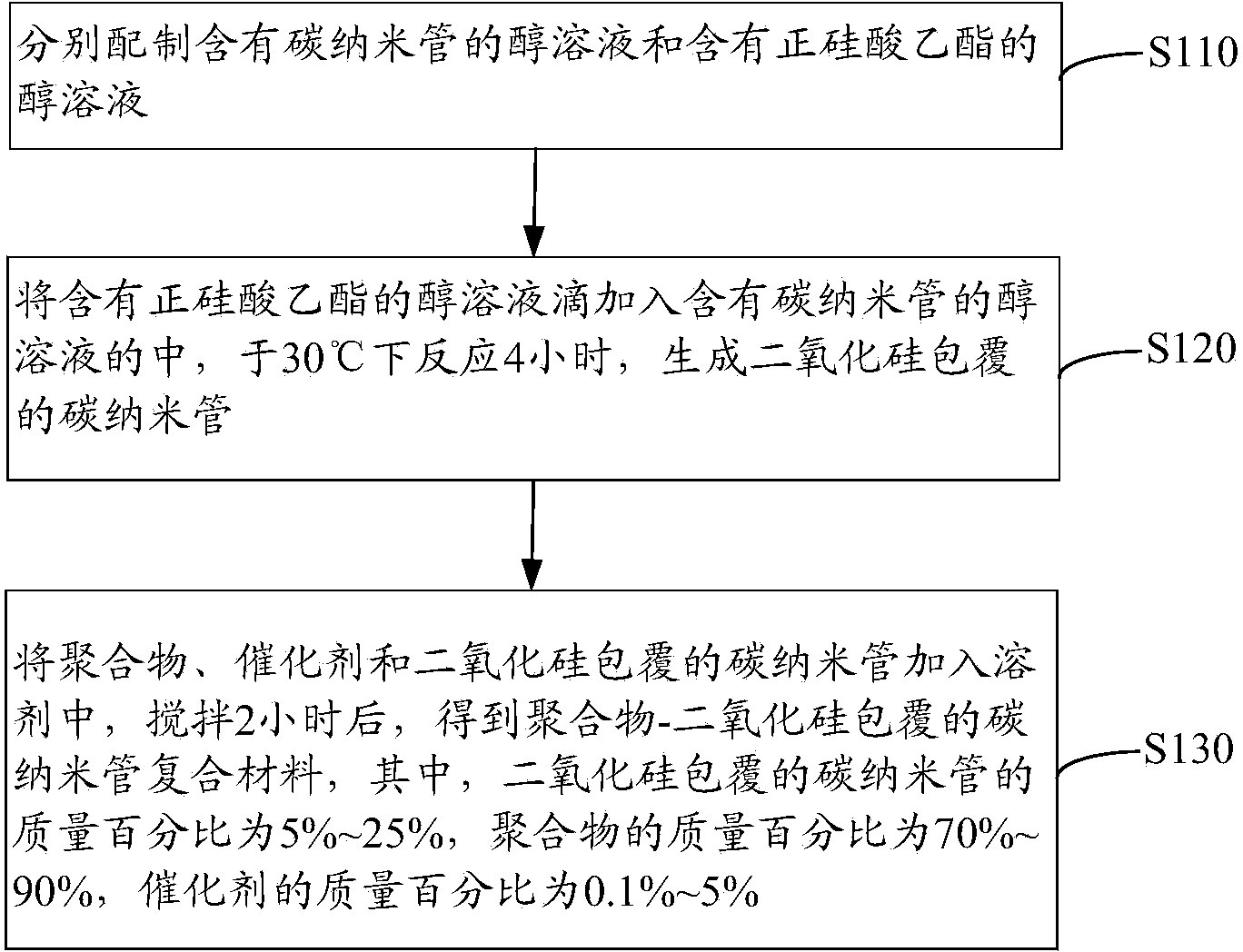

[0050] see figure 2 , the preparation method of the polymer-silicon dioxide-coated carbon nanotube composite material of one embodiment, comprises the steps:

[0051] Step S110: Prepare respectively an alcohol solution containing carbon nanotubes and an alcohol solution containing tetraethylorthosilicate.

[0052] Dissolving carbon nanotubes in absolute ethanol, adding deionized water and cetyltrimethylammonium bromide, adding ammonia water after ultrasonic dispersion, and preparing an alcohol solution containing carbon nanotubes.

[0053] Ammonia as a catalyst. Cetyltrimethylammonium bromide as a surfactant. Preferably, the solid-to-liquid ratio of carbon nanotubes, cetyltrimethylammonium bromide, absolute ethanol, deionized water and ammonia water is 1g:0.5g:80mL:20mL:1mL.

[0054] Dissolve ethyl orthosilicate in absolute ethanol to prepare an alcohol solution containing ethyl orthosilicate. The volume ratio of ethyl orthosilicate to absolute ethanol is preferably 8:10....

Embodiment 1

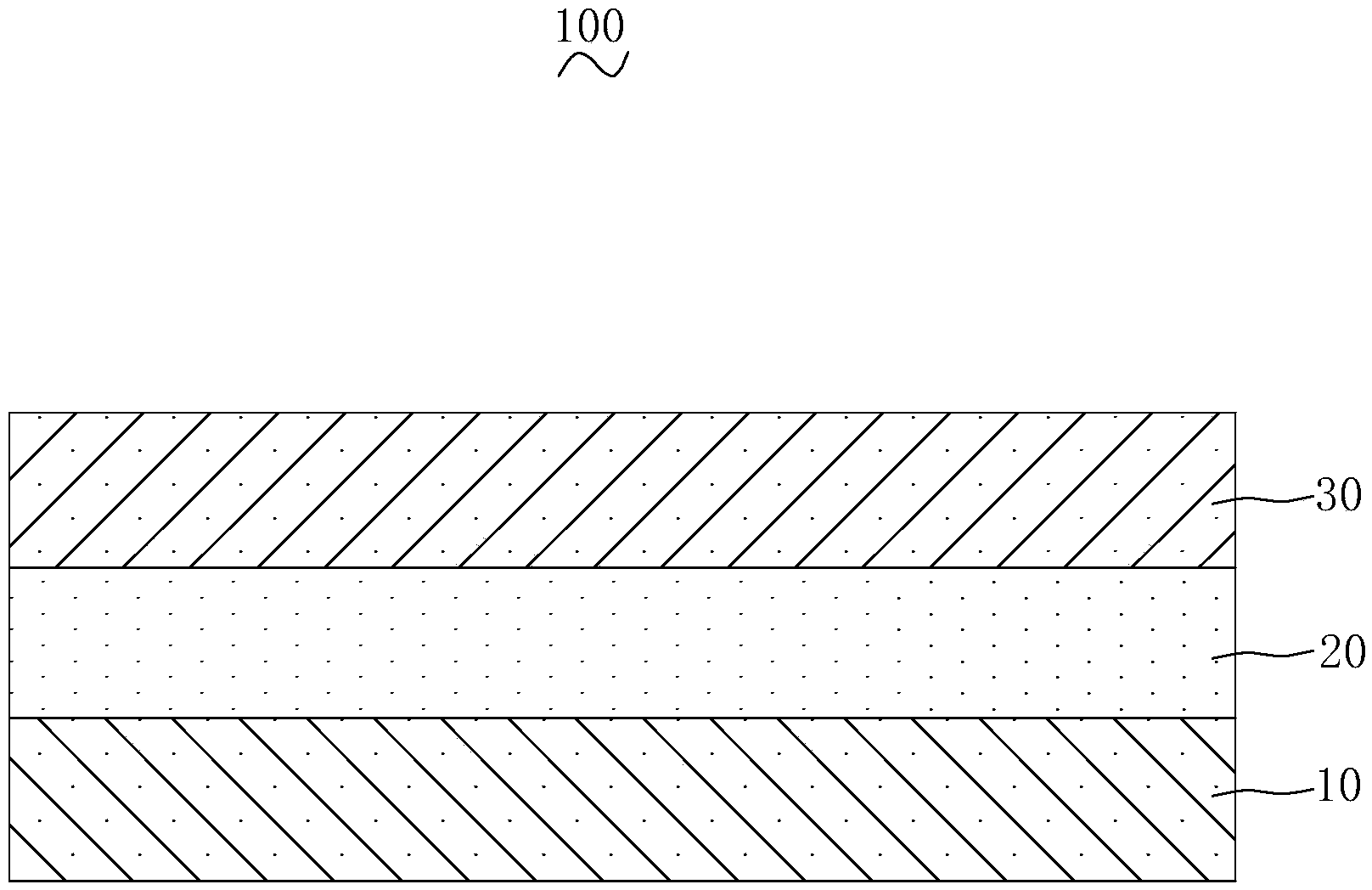

[0086] Preparation of copper clad substrate

[0087] 1. Preparation of silica-coated carbon nanotubes

[0088] (1) Add 80 mL of absolute ethanol, 20 mL of deionized water, 1.0 g of multi-walled carbon nanotubes and 0.5 g of cetyltrimethylammonium bromide into a three-necked flask, ultrasonically disperse for 1 hour, and then add 1 mL of ammonia water to prepare a mixture containing Alcoholic solution of carbon nanotubes;

[0089] (2) Add 8mL tetraethyl orthosilicate and 10mL absolute ethanol into a beaker, stir and mix evenly to prepare an alcohol solution containing tetraethyl orthosilicate, pour the alcohol solution containing tetraethyl orthosilicate into a separatory funnel middle. Keep the temperature in the three-necked flask at 30°C, and at the same time magnetically stir the alcohol solution containing carbon nanotubes, add the alcohol solution containing tetraethyl orthosilicate to the alcohol solution containing carbon nanotubes dropwise, and the dropwise addition ...

Embodiment 2

[0101] Preparation of copper clad substrate

[0102] 1. Preparation of silica-coated carbon nanotubes

[0103] (1) Add 80mL of absolute ethanol, 20mL of deionized water, 1.0g of multi-walled carbon nanotubes and 0.5g of cetyltrimethylammonium bromide into a three-necked flask, ultrasonically disperse for 1 hour, and then add 1mL of ammonia water to prepare Alcoholic solution of carbon nanotubes;

[0104] (2) Add 32mL tetraethyl orthosilicate and 10mL absolute ethanol into a beaker, stir and mix evenly to prepare an alcohol solution containing tetraethyl orthosilicate, and pour the alcohol solution containing tetraethyl orthosilicate into a separatory funnel middle. Keep the temperature in the three-necked flask at 30°C, and at the same time magnetically stir the alcohol solution containing carbon nanotubes, add the alcohol solution containing tetraethylorthosilicate to the alcohol solution containing carbon nanotubes dropwise, and the dropwise addition is completed within 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com