Rubber antioxidant-reduced and modified graphene oxide, as well as preparation method and application thereof

A technology of rubber anti-aging agent and stone oxide, which is applied in the field of reduction of rubber additives and modified graphene oxide and its preparation, can solve the problems of difficulty in uniform dispersion of graphene, difficulty in exerting unique advantages, and weak bonding of rubber interface, etc., to achieve improved Anti-wet skid, avoid migration and volatilization, improve anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Disperse 300mg of graphite oxide into 300ml of deionized water and peel off ultrasonically to form an aqueous dispersion of graphene oxide (GO); add 600mg of rubber antioxidant N-(1,3-dimethyl)butyl-N'-phenyl to Phenylenediamine (anti-aging agent 4020) was dissolved in 120ml of acetone and added to the above GO aqueous dispersion. The reaction was stirred at 80°C for 4.5 hours. The reaction product was washed with ethanol and placed in a vacuum oven at 60°C. Dry to constant weight to obtain antioxidant 4020 modified graphene (4020-G). In order to better illustrate the characteristics of the present invention, the graphene reduced by hydrazine hydrate was prepared according to the existing conventional method and named HH-G for comparison.

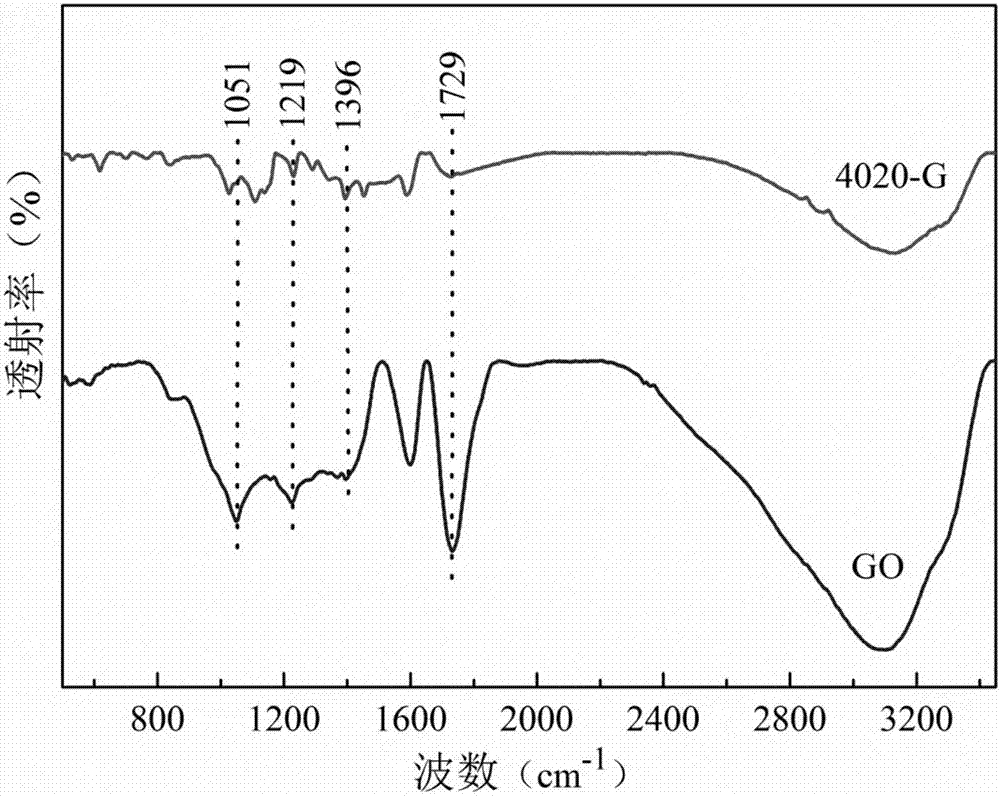

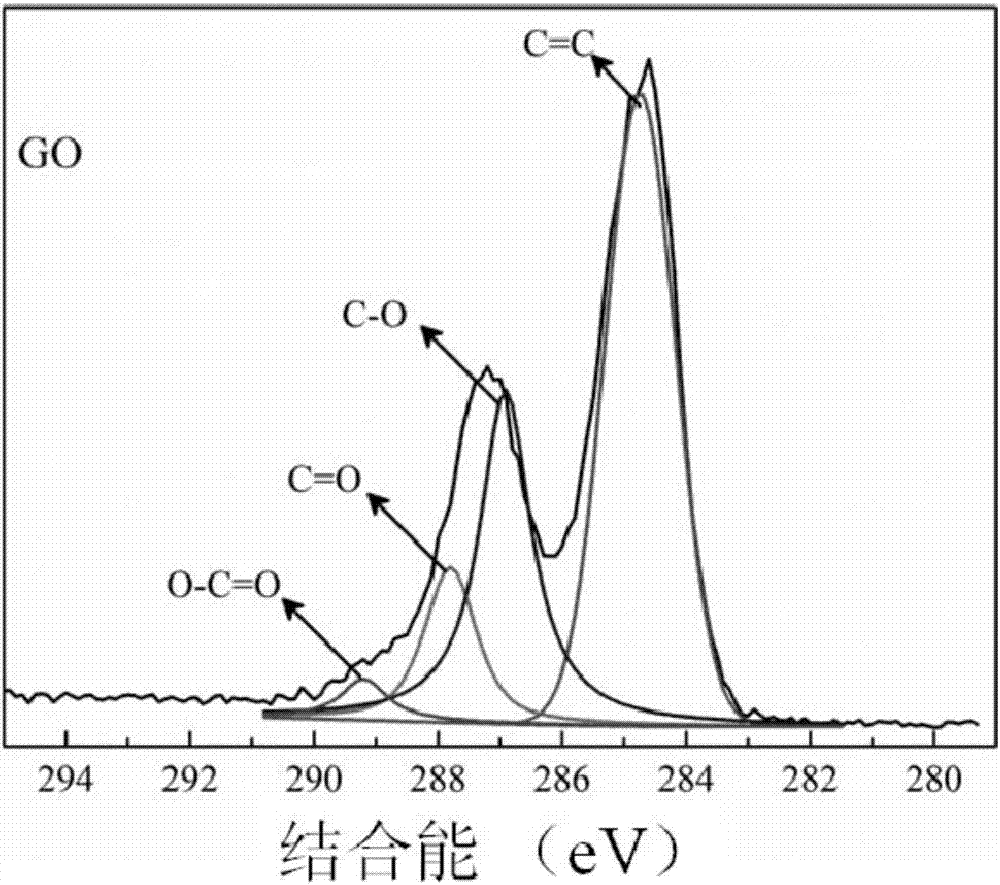

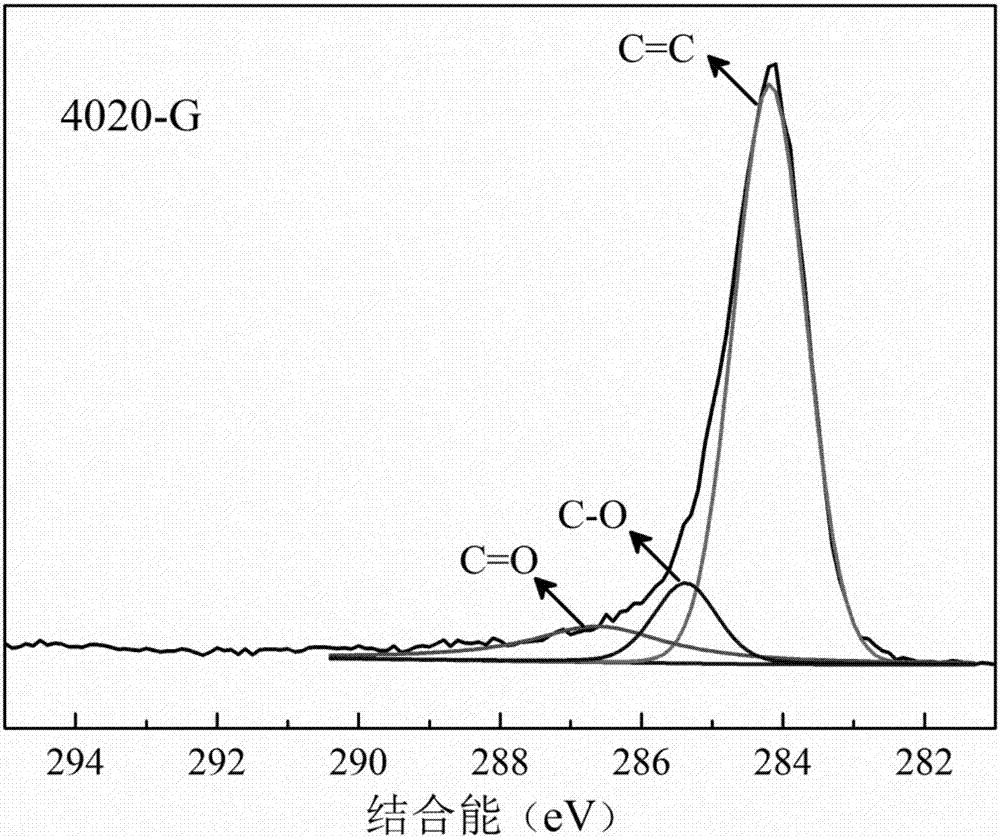

[0034] The infrared spectra (FTIR) of 4020-G and GO prepared in this example are as follows figure 1 Shown. It can be seen from the figure that compared with the FTIR spectrum of GO, the spectrum of 4020-G is at 1729 cm -1 , 1396 cm -1...

Embodiment 2

[0038] Disperse 200mg of graphite oxide into 400ml of deionized water and peel off ultrasonically to form an aqueous dispersion of graphene oxide (GO); dissolve 600mg of rubber antioxidant N-phenyl-N'-cyclohexyl p-phenylenediamine (antioxidant 4010) In 60ml of toluene and added to the above GO aqueous dispersion, the reaction was stirred at 60°C for 8 hours. After the reaction product was washed with ethanol, it was placed in a vacuum oven and dried to constant weight at 50°C to obtain the antioxidant 4010 modified graphene (4010-G).

[0039] FTIR and 13 C NMR results show that compared with GO, the oxygen-containing functional group peak intensity in 4010-G is significantly reduced, and organic peaks appear on the spectrum, indicating that antioxidant 4010 can effectively reduce GO, and some antioxidants are loaded on it. The reduced graphene oxide surface.

[0040] The 4010-G and HH-G prepared in this example were compounded with SBR to prepare a rubber composite material. The f...

Embodiment 3

[0042] Disperse 150mg of graphite oxide into 100ml of deionized water and peel off ultrasonically to form an aqueous dispersion of graphene oxide (GO); 300mg of rubber antioxidant N-isopropyl-N'-phenyl-p-phenylenediamine (antioxidant 4010NA) Dissolve it in 20ml of absolute ethanol and add it to the GO aqueous dispersion. Stir and react at 100°C for 1 hour. After washing with ethanol, the reaction product is placed in a vacuum oven and dried at 55°C to a constant weight. Obtain the antioxidant 4010NA modified graphene (4010NA-G).

[0043] FTIR and XPS showed that the oxygen-containing functional groups in 4010NA-G were significantly reduced compared to GO, indicating that the antioxidant 4010NA can effectively reduce GO.

[0044] The 4010NA-G and HH-G prepared in this example are compounded with SBR to prepare a rubber composite material. The formula is the same as in Example 1, except that the antioxidant 4020 is replaced with 4010NA, while ensuring that all formulas contain 4010NA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com