Aramid III fiber with fluorine-containing surface and preparation method thereof

A fiber and aramid fiber technology, which is applied in the field of surface fluorine-containing aramid III fiber and its preparation, can solve the problems of fluorination equipment corrosion and reduce fluorination rate, etc., to prolong service life, increase fluorination rate, and increase activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

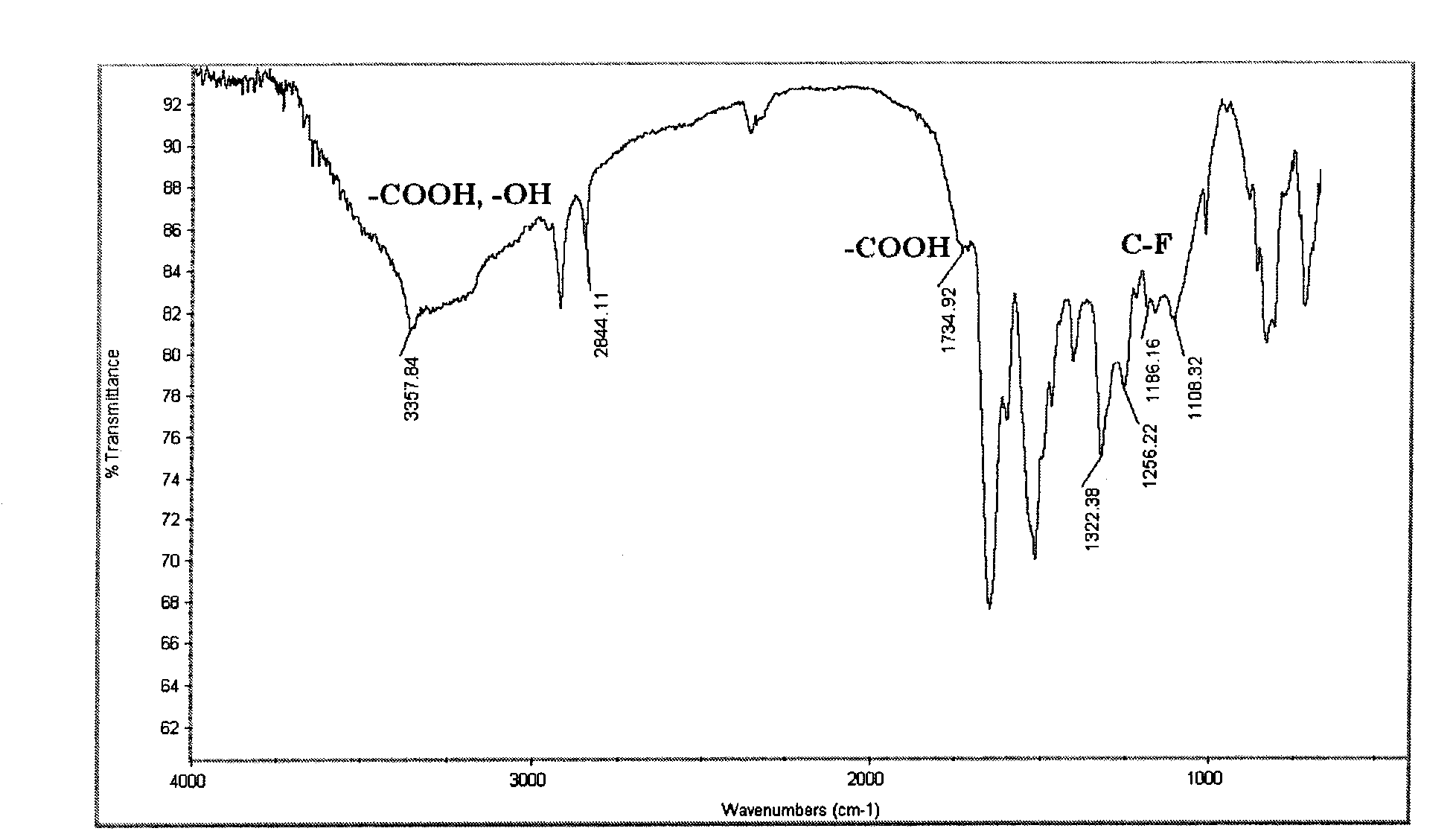

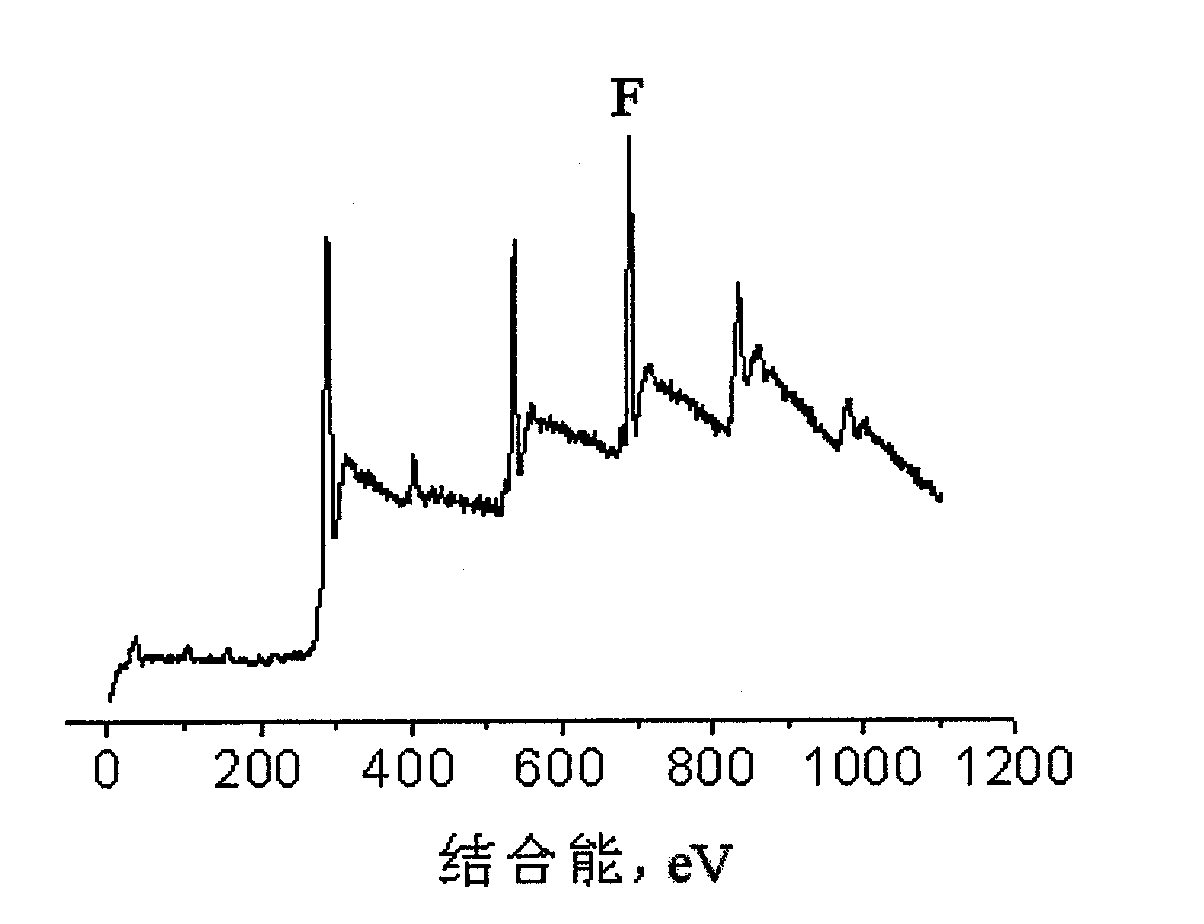

[0032] First place the aramid III fiber prepared by the synthetic monomer molar ratio: TPC:PABZ:PDA=100:60:40 in a closed vacuum reactor, then vacuumize, and replace the air in the reactor with nitrogen three times , fill the vacuum reactor with a mixed gas of fluorine / nitrogen, control the partial pressure of fluorine in the reactor to 10KPa, and raise the temperature to 50°C for surface fluorination treatment for 20 minutes, and finally put the wound fiber in the air Store in the atmosphere for at least 1 hour to obtain the aramid fiber III with carbon-fluorine covalent bonds and carboxyl and hydroxyl groups on the surface.

Embodiment 2

[0034] In this embodiment, except that the partial pressure of fluorine gas in the reactor is controlled to 0.1 KPa, the rest of the fluorination process and the composition of the aramid fiber III are the same as those in Embodiment 1, so they are omitted here.

Embodiment 3

[0036] In this embodiment, except that the partial pressure of fluorine gas in the reactor is controlled to be 50KPa, the rest of the fluorination process and the composition of the aramid fiber III are the same as those in Embodiment 1, so they are omitted here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com