Composite material of polyphenyl ether/nylon/carbon nano tube and preparation method thereof

A technology of carbon nanotubes and composite materials, which is applied in the field of plastic alloys, can solve the problems of nylon/polyphenylene ether alloy limitations, and the difficulty of simultaneously improving material strength and modulus, so as to improve strength and modulus, improve mechanical properties and thermal Effect of improved properties, impact strength and Young's modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

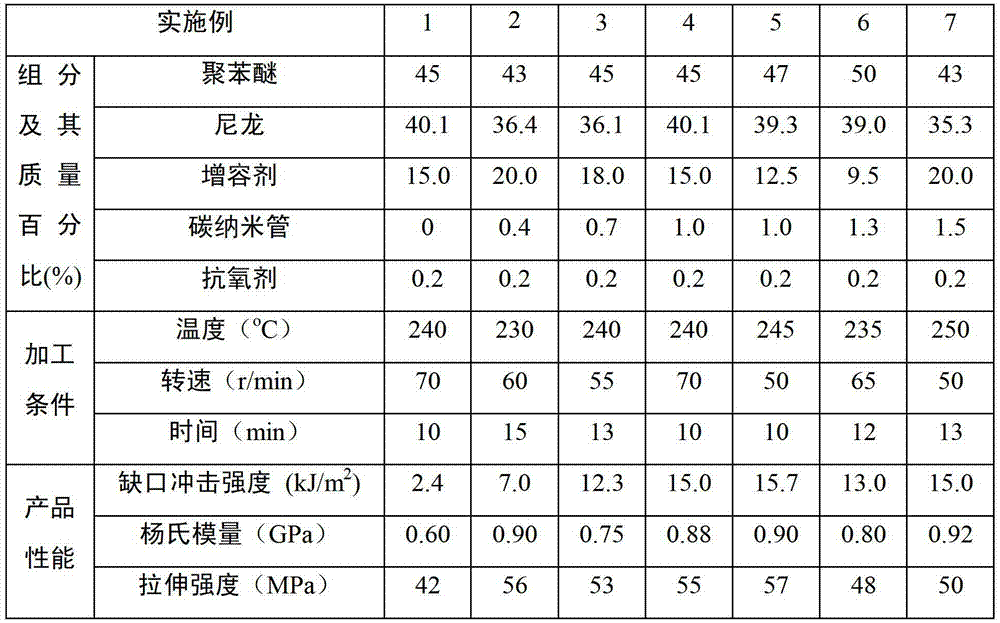

Embodiment 1 to 7

[0024] The carbon nanotubes used in the formulations of Examples 1 to 7 are carbon nanotubes with a diameter of 20±5 nm and a length of 1˜10 μm after amination treatment.

[0025] The amination treatment method of carbon nanotubes is as follows:

[0026] First, ultrasonically disperse 100 mg of carbon nanotubes, 5 g of potassium hydroxide, and 100 mL of ethanol together for 30 min, then heat and reflux and stir for 8 h to react, filter the reaction product, wash with ethanol for 3 times and wash with deionized water until the filtrate is neutral, and place in a vacuum Dry under reduced pressure in an oven for 12 hours at 80° C. to obtain hydroxylated carbon nanotubes.

[0027] Then, mix 50mg of hydroxylated carbon nanotubes with 50mL of toluene and ultrasonically disperse for 30min, heat to 80°C while stirring, and add 2ml of toluene solution with a concentration of 5wt% aminosilane dropwise at a rate of 5ml / min, and react at constant temperature for 8h Finally, the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com