Calcium chloride hexahydrate phase change energy storage material composition

A technology of material composition and phase change energy storage, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of uneven distribution of nucleating agents and ineffective phase change of products, and achieve excellent temperature regulation function , high phase transition stability, and high phase transition latent heat value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

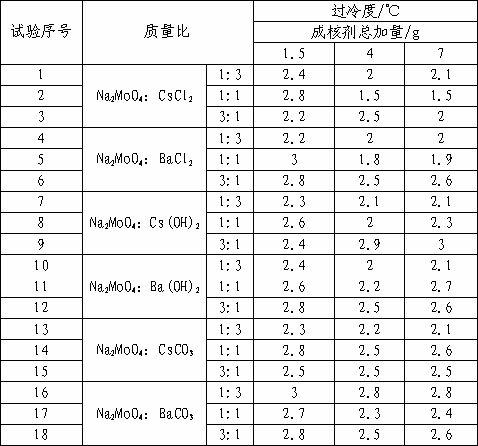

[0029] First take anhydrous CaCl 2 and H 2 O is dissolved in a molar ratio of 1:6 to make CaCl 2 ·6H 2 O, and cooled to 40°C for further use. Dissolve the nucleating agent composition in 100 g of liquid CaCl at 40°C with stirring 2 ·6H 2 O, the stirring time was 1 hour. According to the T-History test method to test its supercooling degree, the cooling environment is a constant temperature water bath at 15°C. The analysis results are shown in Table 1:

[0030] Table 1 Effect of composition and dosage of nucleating agent on undercooling degree of phase change material

[0031]

Embodiment 2

[0033]Get the 200g liquid CaCl prepared in embodiment 1 2 ·6H 2 O, while maintaining 40°C and stirring, add 4g Na in sequence 2 MoO 4 , 4gCsCl 2 , 6gKCl, 3gNH 4 Cl, 1gCaSO4, 0.6gNaCl, stirring time is 1 hour. The phase transition temperature of the obtained mixture was measured to be 24.3° C., the supercooling degree was 2.1° C., and the phase transition latent heat value was 185.1 kJ / kg. After 3000 times of cold and heat cycle tests, the latent heat value of phase transition was measured to be 176.7kJ / kg (the latent heat value decreased by 4.5%), and a small amount of water precipitated visually after crystallization.

Embodiment 3

[0035] Get the 100g liquid CaCl prepared in embodiment 1 2 ·6H 2 O, while maintaining 40°C and stirring, add 1.75g Na 2 MoO 4 , 5.25gBaCl 2 , 8gKCl, 5gNH 4 Cl, 1gCaSO4, 0.5gNaCl, stirring time is 1 hour. The phase transition temperature of the obtained mixture was measured to be 23.6° C., the supercooling degree was 2.5° C., and the phase transition latent heat value was 183.4 kJ / kg. After 3000 times of cold and heat cycle tests, the latent heat value of phase transition was measured to be 172.6kJ / kg (the latent heat value decreased by 5.9%), and a small amount of water precipitated visually after crystallization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase change latent heat value | aaaaa | aaaaa |

| Phase change latent heat value | aaaaa | aaaaa |

| Phase change latent heat value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com