High-efficiency air handler

a high-efficiency, air handler technology, applied in the field of air handlers, can solve the problems of large conventional air handlers, high fan static pressures found in larger systems, and large fan energy input of fan energy, and achieve the effect of increasing the energy input of the fan greatly, and reducing the noise of the fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

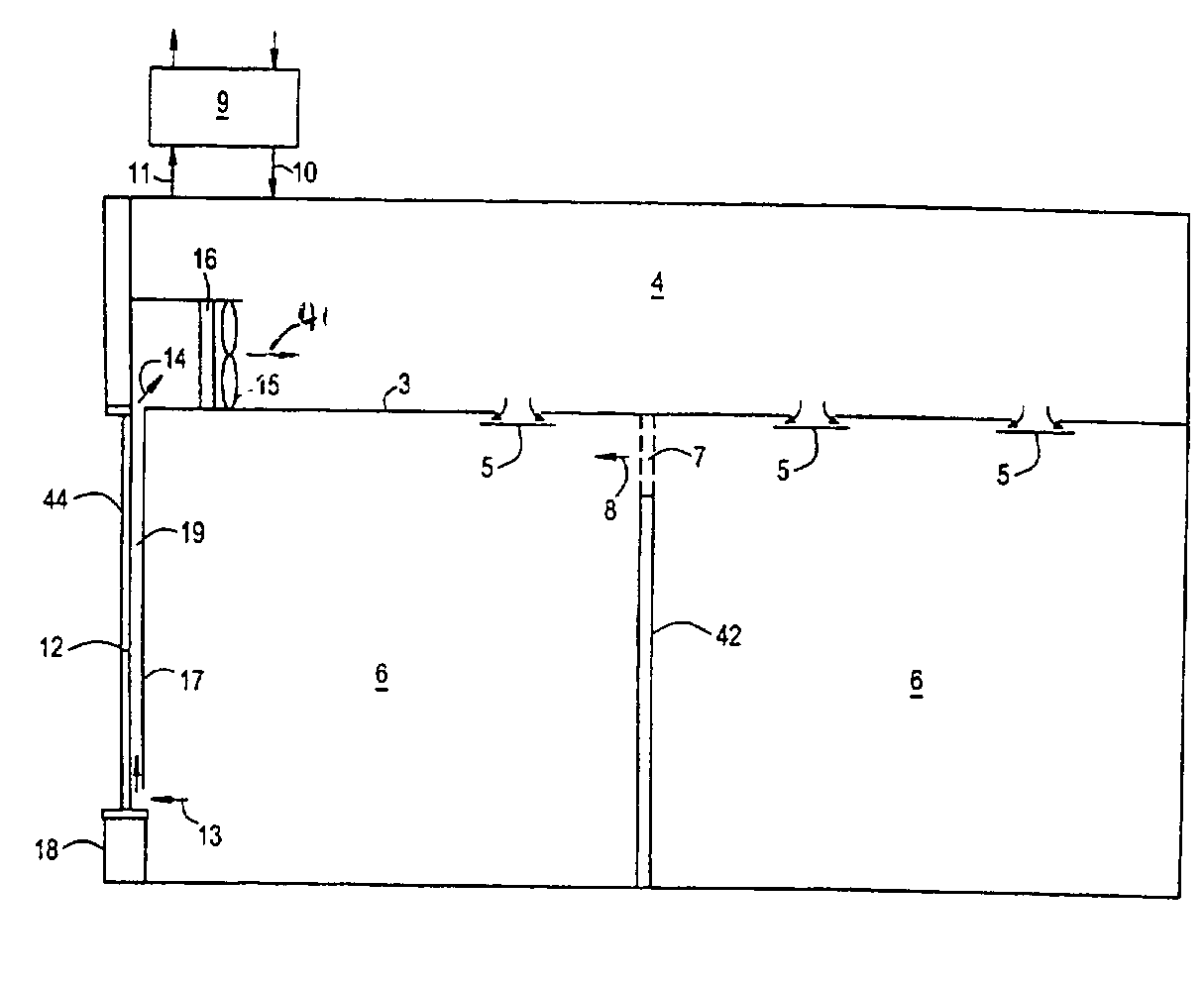

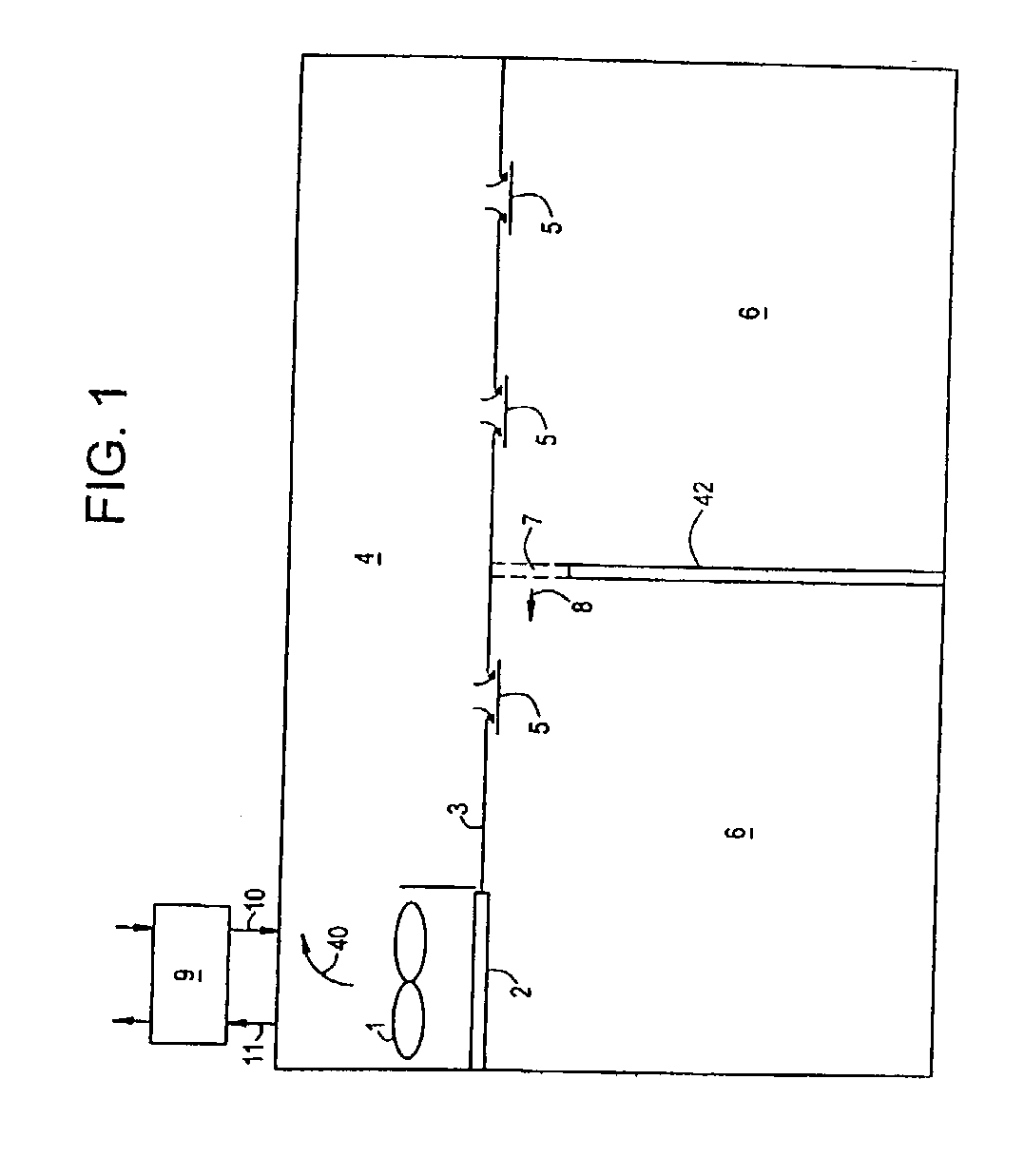

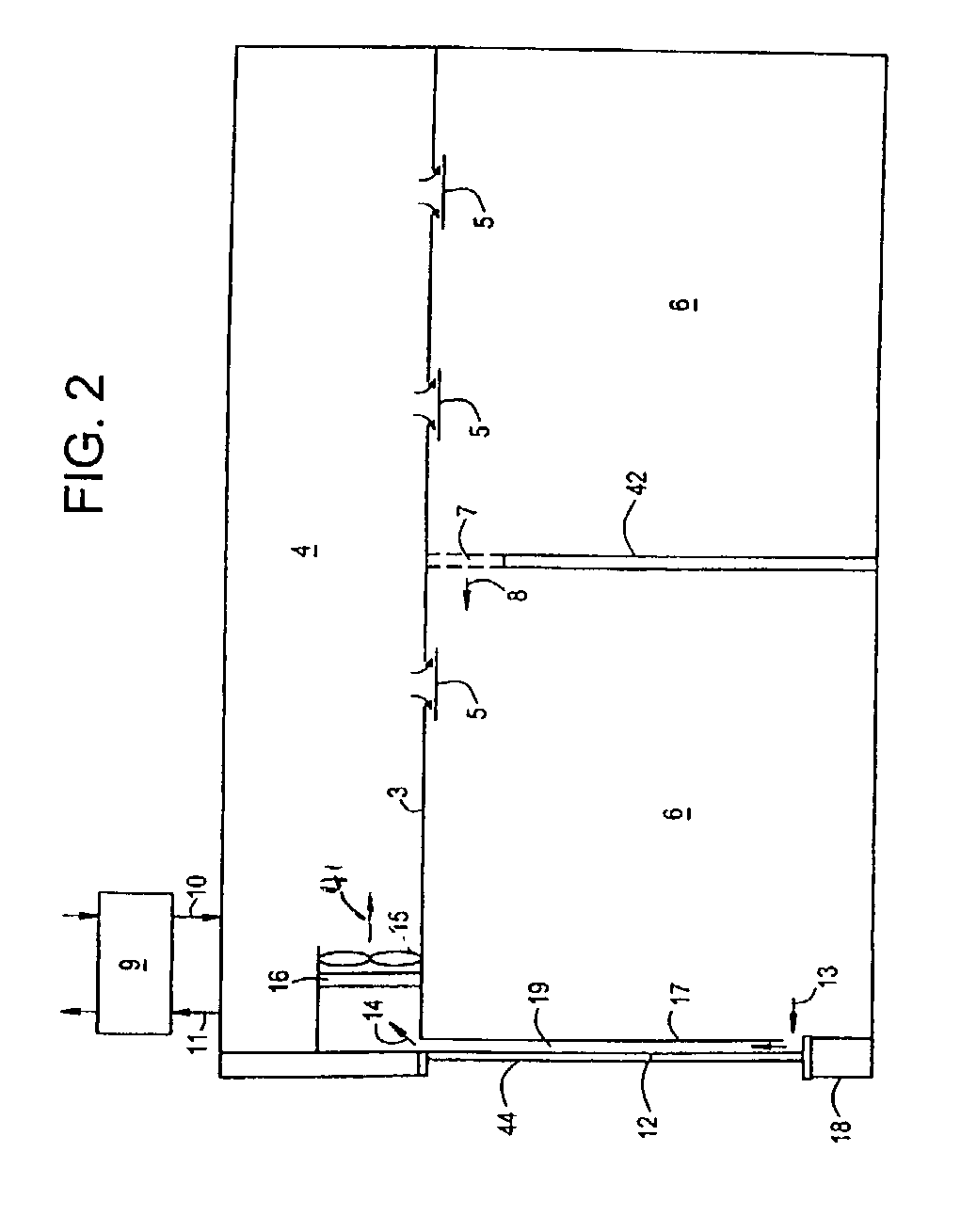

[0032] Preferred system embodiment: FIG. 1 shows a preferred embodiment of the invention. Fan, 1, draws air across coil, 2, where it is cooled or heated to create a supply air stream 40. Ceiling, 3, defines the bottom of a ceiling plenum, 4, that serves as a flow path for air leaving the fan. Vents, 5, provide openings into that allow supply air to mix with air in an occupied portion of the building space, 6. Vent, 7, provides an opening to allow air, 8, to return through a partition 42 in the space. A separate ventilation system, 9, provides dehumidified outside air, 10, to the space and recovers energy from exhaust air, 11.

[0033] The fan may be a propeller or centrifugal fan. It would have to provide only a small static pressure, typically less than 0.2 inches of water. The low static pressures favor the uses of low-speed fans, which should help to reduce fan sound levels and should reduce fan energy use.

[0034] The coil can contain water or brine or a refrigerant. The supply air t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com