Phase change energy storage device

A phase change energy storage and phase change unit technology, applied in energy storage, thermal storage equipment, lighting and heating equipment, etc. The effect of small charging volume, easy implementation and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

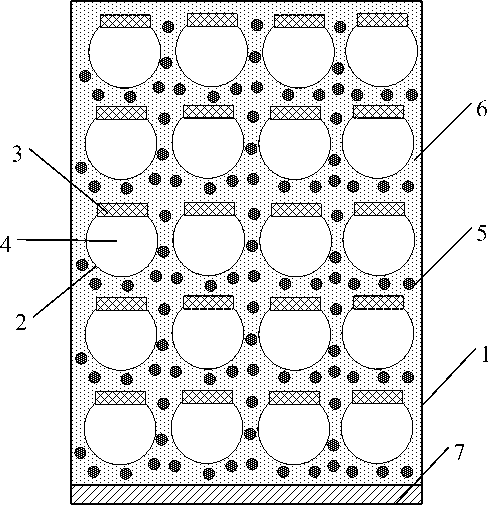

[0031] Embodiment 1 shows a typical application of the phase change energy storage device of the present invention, which absorbs and stores the heat generated during the operation of the laser through the paraffin phase change unit, so as to ensure that the laser will not be burned due to the intensive release of heat when working in a single pulse . figure 1 Schematic diagram of the phase change energy storage device.

[0032] Such as figure 1 As shown, the phase change energy storage device in this embodiment is composed of a shell 1 , a paraffin chamber 2 , a plastic cover 3 , paraffin 4 , metal particles 5 and a low melting point metal 6 . As the peripheral frame of the phase change energy storage device, the shell is closely attached to the heat source. The paraffin cavity 2, the plastic cover 3 and the paraffin 4 form a paraffin phase change unit, which is evenly filled in the shell. The paraffin phase change unit is the heat absorbing part of the phase change energy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com