Formation agent and preparation method

A technology of potassium hydroxide and potassium hydrogen fluoride, which is applied in the coating process of metal materials, etc., can solve problems such as physical health and environmental hazards, environmental pollution to human health, and restrictions on the use of chromate, so as to achieve low human health hazards and environmental protection. Strong, excellent coating adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

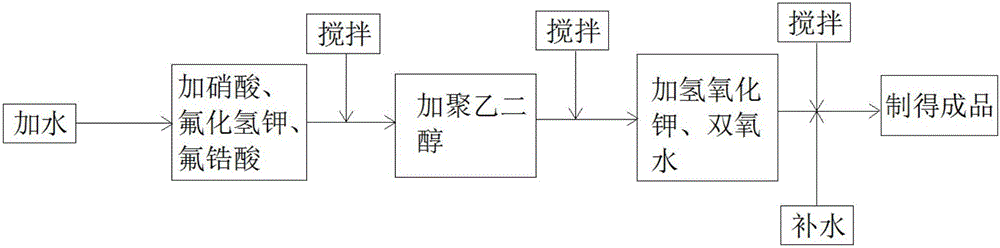

Image

Examples

Embodiment 1

[0026] A chemical forming agent, the specific components and weight ratios include: 5% nitric acid at 50% concentration, 2.5% potassium hydrogen fluoride, 0.01% fluozirconic acid, 1% polyethylene glycol of analytical grade, and potassium hydroxide of analytical grade 18.49%, hydrogen peroxide 4%, and pure water 69%.

Embodiment 2

[0028] A chemical forming agent, the specific components and weight ratios include: 5% nitric acid at 50% concentration, 3.5% potassium hydrogen fluoride, 0.01% fluozirconic acid, 5% polyethylene glycol of analytical grade, and potassium hydroxide of analytical grade 20%, hydrogen peroxide 4.49%, and pure water 62%.

Embodiment 3

[0030] A chemical forming agent, the specific components and weight ratio include: 5% nitric acid at 50% concentration, 0.5% potassium hydrogen fluoride, 0.01% fluozirconic acid, 20% polyethylene glycol of analytical grade, and potassium hydroxide of analytical grade 11%, hydrogen peroxide 3.1%, and pure water 60.39%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com