Chromium-free coating agent and preparation method thereof

A technology of coating agent and silane coupling agent, which is applied in the field of chromium-free coating agent and its preparation, can solve the problems of not meeting the requirements of the process, high product cost, high cost, etc., and achieve the improvement of adhesion and corrosion resistance, treatment Short, manageable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

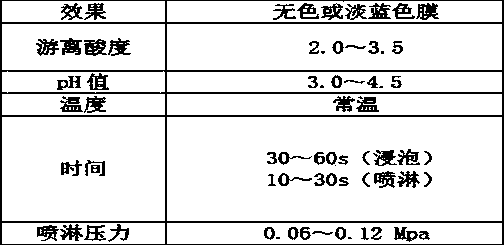

Image

Examples

Embodiment 1

[0051] Every 1000Kg of chromium-free film agent is made of the following raw materials:

[0052]Fluorozirconic acid 20Kg, silane coupling agent (KH-550) 20 Kg, silane coupling agent (KH-560) 3 Kg, zirconium oxychloride 8 Kg, citric acid 5 Kg, water 944 Kg.

[0053] Its preparation method comprises the following steps in turn:

[0054] (1) Add water to the reactor;

[0055] (2) Add silane coupling agent KH-550 into the reaction kettle, and stir until the silane coupling agent is completely hydrolyzed, and the stirring time is 7-9 hours;

[0056] (3) Add silane coupling agent KH-560 into the reaction kettle, and stir until the silane coupling agent is completely hydrolyzed, and the stirring time is 7-9 hours;

[0057] (4) Add fluozirconic acid into the reaction kettle, stir evenly, and make the solution clear, and the stirring time is 0.5-1.5 hours;

[0058] (5) Add zirconium oxychloride to the reaction kettle, stir evenly, and make the solution clear, and the stirring time i...

Embodiment 2

[0067] Every 1000Kg of chromium-free film agent is made of the following raw materials:

[0068] Fluorozirconic acid 20Kg, silane coupling agent (KH-550) 50 Kg, silane coupling agent (KH-560) 3 Kg, zirconium oxychloride 8 Kg, citric acid 5 Kg, water 914 Kg.

[0069] The preparation method and usage method are the same as in Example 1.

Embodiment 3

[0071] Every 1000Kg of chromium-free film agent is made of the following raw materials:

[0072] Fluorozirconic acid 40Kg, silane coupling agent (KH-550) 30 Kg, silane coupling agent (KH-560) 5 Kg, zirconium oxychloride 10 Kg, citric acid 7Kg, water 908 Kg.

[0073] The preparation method and usage method are the same as in Example 1.

[0074] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com