Method for coating normal-temperature black phosphating film on steel surface

A technology of steel surface and phosphating film, applied in phosphating and other directions, can solve problems such as hydrolysis, and achieve the effects of less slag, faster film formation, and less use of drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

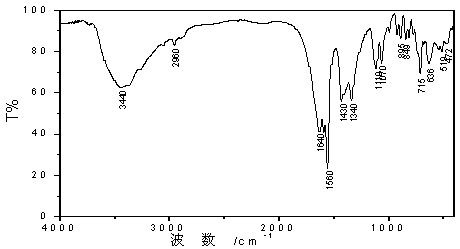

Image

Examples

Embodiment 1

[0026] (1) React antimony trichloride (SbCl3) with tartaric acid to form a trivalent antimony tartrate complex;

[0027] Preparation method: Dissolve 2.3 g of antimony trichloride and 6 g of tartaric acid in water, add sodium hydroxide solution dropwise while stirring until the reaction solution is clear, and obtain a trivalent antimony tartrate complex.

[0028] (2) dissolving the complex of trivalent antimony tartrate in the phosphating solution to obtain the phosphating solution containing antimony tartrate;

[0029] Preparation method: 6g / L of zinc oxide, 35g / L of phosphoric acid, 30g / L of Maziv's salt, 1g / L of nickel nitrate are dissolved and clarified, and then added to the trivalent antimony tartrate complex solution to obtain blackened phosphating liquid.

[0030] (3) Phosphating, that is, placing the cleaned steel sample in a phosphating solution containing trivalent antimony tartrate, and performing electrolytic phosphating at room temperature for 10 minutes;

[00...

Embodiment 2

[0039] (1) React antimony trichloride (SbCl3) with citric acid to generate trivalent antimony citrate complex;

[0040] Preparation method: dissolve 3.8 g of antimony trichloride and 12 g of citric acid in water, add sodium hydroxide solution dropwise while stirring until the reaction solution is clear, and obtain a trivalent antimony citrate complex.

[0041] (2) dissolving the trivalent antimony citrate complex in the phosphating solution to obtain a phosphating solution containing antimony citrate;

[0042] Preparation method: 8g / L of zinc oxide, 60g / L of phosphoric acid, 20g / L of Maziv's salt, 3g / L of nickel nitrate are dissolved and clarified, and then added to the trivalent antimony complex solution of citric acid to obtain black phosphorus liquid.

[0043] (3) Phosphating, that is, placing the cleaned steel sample in a phosphating solution containing trivalent antimony tartrate, and performing electrolytic phosphating at room temperature for 20 minutes;

[0044] The p...

Embodiment 3

[0048] (1) Reaction of antimony trioxide (Sb2O3) with disodium edetate to form trivalent antimony complex of edetate;

[0049] Preparation method: Dissolve 0.95 g of antimony trioxide and 4 g of disodium edetate in water, add sodium hydroxide solution dropwise while stirring until the reaction liquid is clear, and obtain trivalent antimony edetate complex.

[0050] (2) dissolving the trivalent antimony EDTA complex in the phosphating solution to obtain a phosphating solution containing antimony EDTA;

[0051] Preparation method: 5g / L of zinc oxide, 30g / L of phosphoric acid, 40g / L of Mazoff salt, and 2g / L of nickel nitrate are dissolved and clarified, and then added to the trivalent antimony complex solution of ethylenediaminetetraacetic acid to obtain Blackened phosphating solution.

[0052] (3) Phosphating, that is, place the cleaned steel sample in a phosphating solution containing trivalent antimony ethylenediaminetetraacetic acid, and perform electrolytic phosphating at r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com