Rock bit

A technology of roller cone bits and drill bits, which is applied to drill bits, drill pipes, drill pipes, etc., can solve the problems of sediment entry, seal wear, bearing wear, etc., and achieve the effect of suppressing horizontal vibration and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

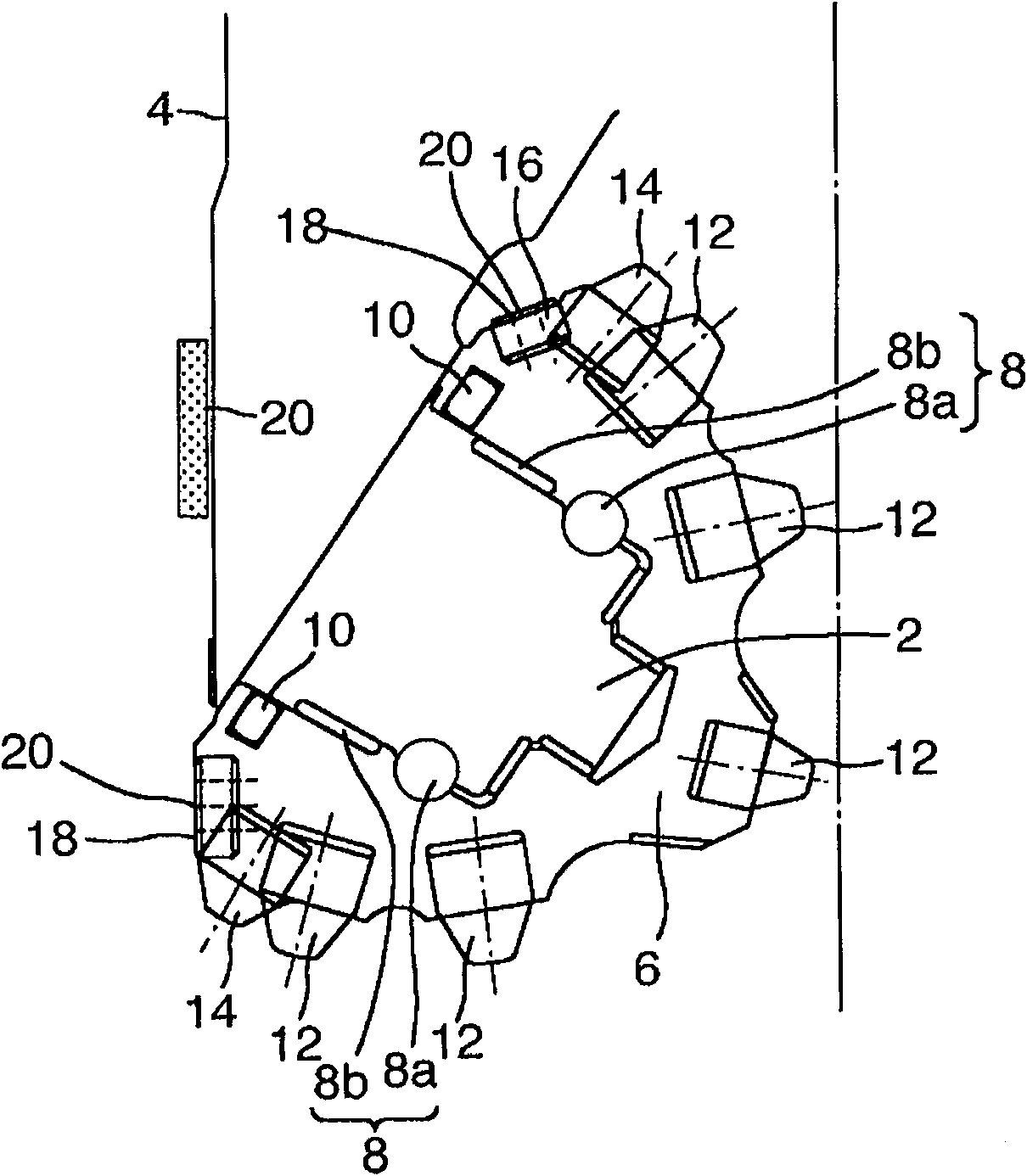

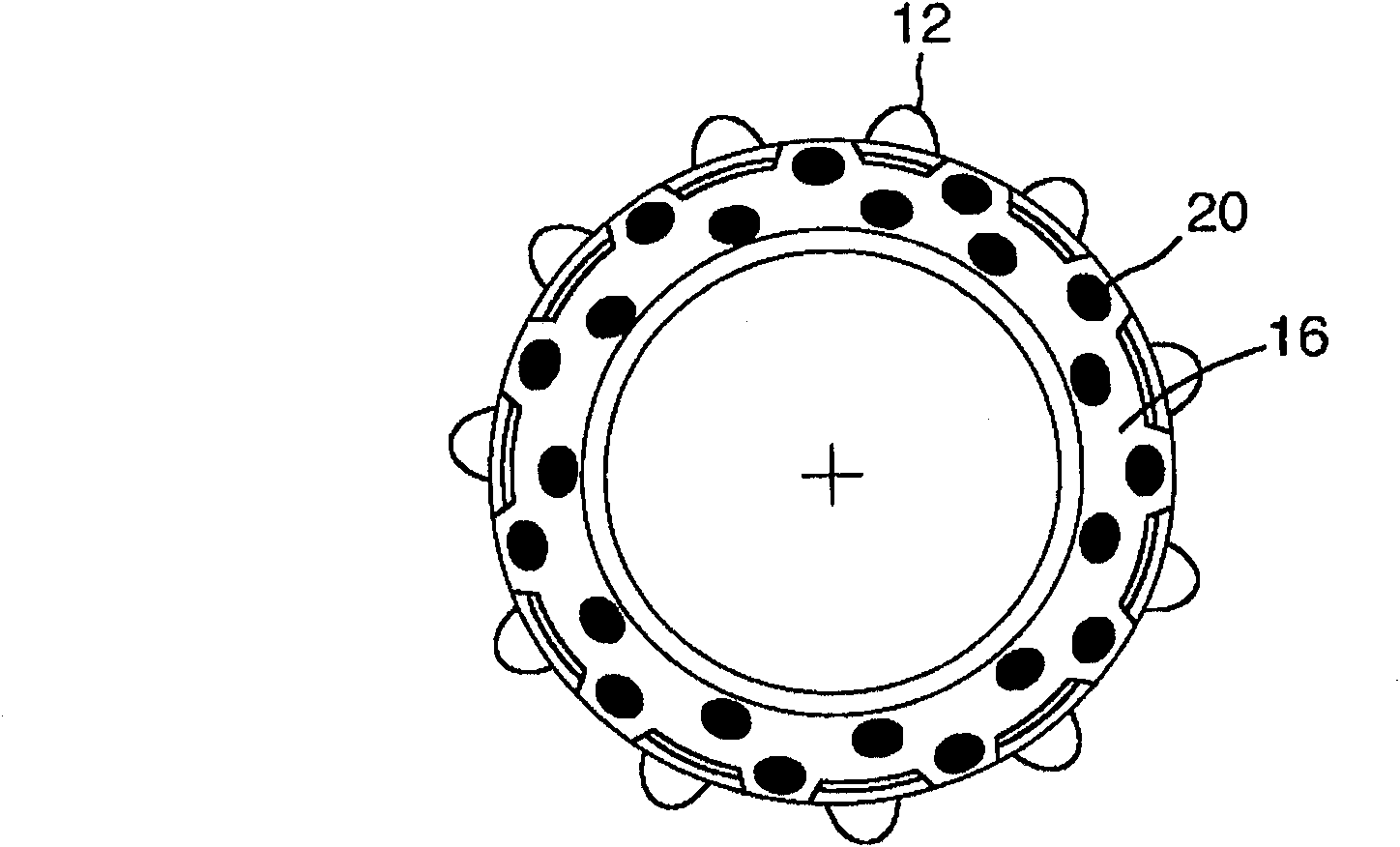

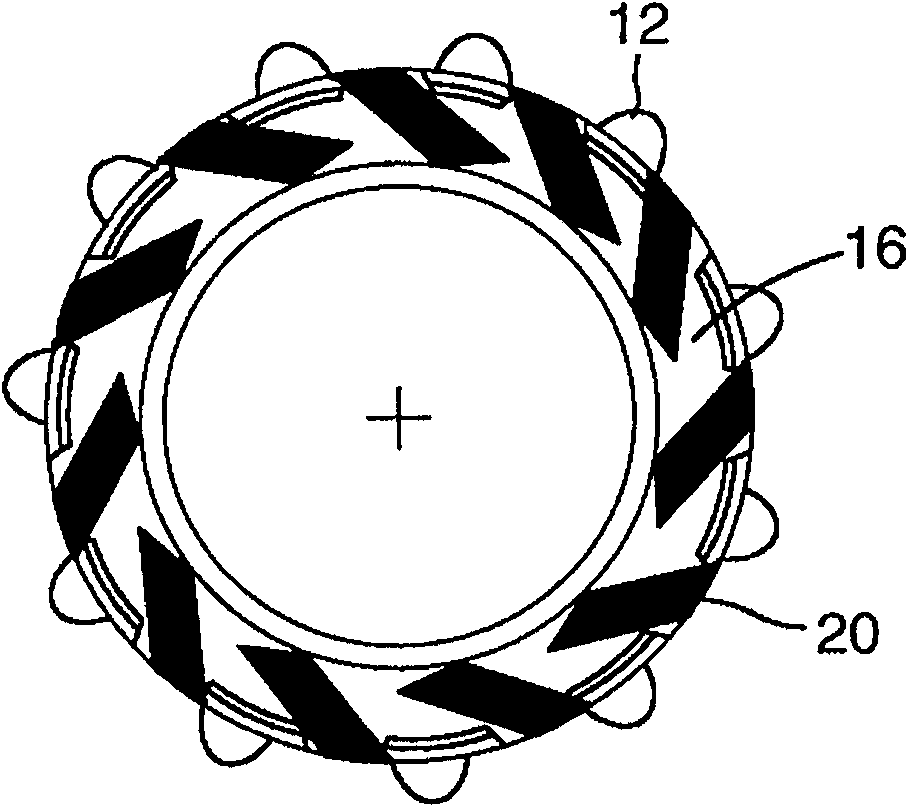

[0037] refer to figure 1One embodiment of the roller cone bit according to the present invention is described. The roller cone bit includes a bit body 4 having a journal portion 2 , a conical portion 6 rotatable relative to the bit body 4 , and a support portion 8 between the conical portion 6 and the journal portion 2 . The support portion 8 includes a ball bearing 8a and a metal bearing 8b. The roller cone bit further comprises a seal 10 disposed between the conical portion 6 and the journal portion 2 for sealing the bearing portion 8 . A plurality of carbide tips 12 and 14 are embedded in the tapered portion 6 . The cemented carbide tip includes a cemented carbide tip 12 that contacts the bottom of the well and a trimmed tip 14 that contacts the sidewall of the well.

[0038] The tapered portion 6 includes a trimmed surface 16 in contact with the well sidewall. A cemented carbide conditioning surface tip 18 is disposed on the conditioning surface 16 . The diamond comp...

Embodiment approach 2

[0052] Now, refer to Figure 9 A roller cone bit according to another embodiment of the present invention will be described.

[0053] Like the roller cone bit according to Embodiment 1, this tricone bit includes a bit body 4 having a journal portion 2 , a tapered portion 6 rotatable relative to the bit body 4 , and Between the supporting part 8. The support portion 8 includes a ball bearing 8a and a metal bearing 8b. The roller cone bit further comprises a seal 10 disposed between the conical portion 6 and the journal portion 2 for sealing the bearing portion 8 .

[0054] Unlike the case of Embodiment 1, a ring portion 30 is provided on the outer peripheral portion of the drill body 4 . A ring bit 32 is provided at the end of the ring portion 30 . Furthermore, the conical portion 6 of the tricone bit does not include a trimming tip or a trimming tip in contact with the sidewall of the well, only a cemented carbide tip 12 in contact with the bottom of the well.

[0055] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com