Production and using method of environmentally-friendly noble metal mineral processing reagent

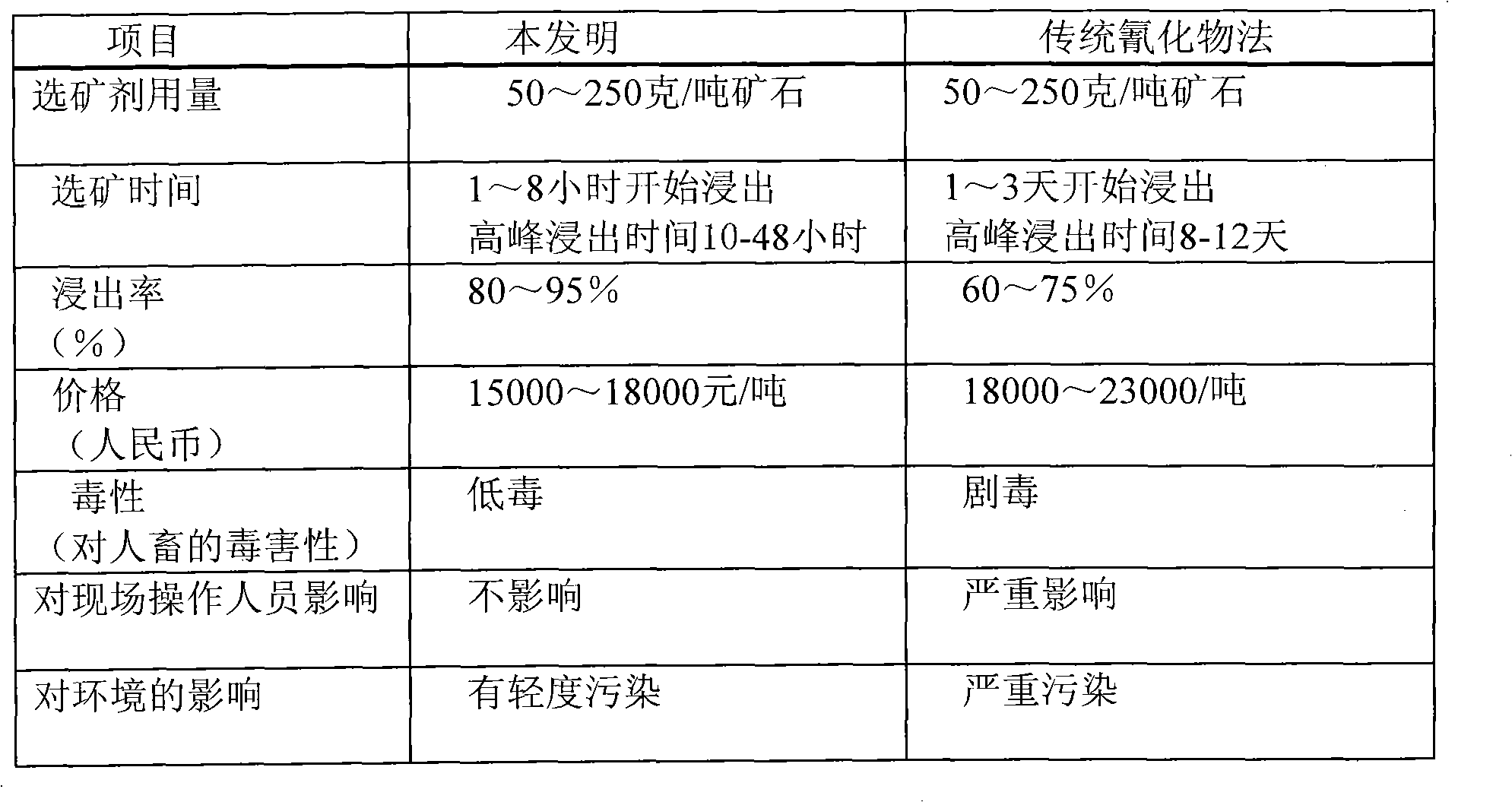

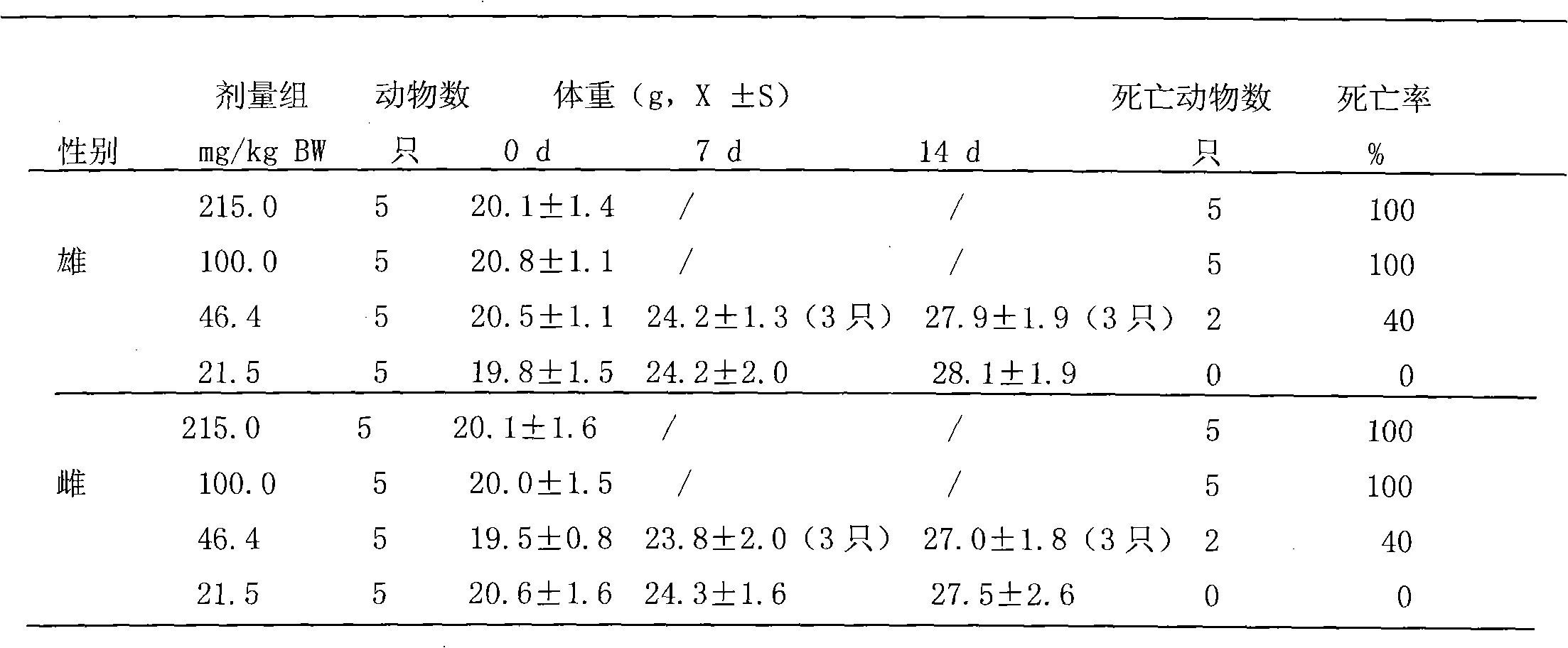

A production method and technology of precious metals, applied in the field of beneficiation agents, can solve problems such as polluted water sources and unstable product quality, and achieve the effects of high safety, low cost, and environmentally friendly products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The weight ratio of yellow blood salt and urea is 1: 1.5, and yellow blood salt and urea are mixed, put into reactor, in the process of slowly heating up, add pH adjusting agent sodium hydroxide and sodium carbonate, after being heated to molten state, The pH value of the melt is 8-13 (take a small amount of melt test sample to cool and dissolve in water to measure the pH value), keep the melting temperature for 5-10 minutes, and cool to normal temperature to obtain a block-shaped environment-friendly precious metal mineral processing agent.

Embodiment 2

[0024] The weight ratio of yellow blood salt and urea is 1:4. Mix yellow blood salt and urea and put them in the reactor. During the slow temperature rise process, add pH regulator sodium hydroxide and ammonium bicarbonate, and heat to molten state , so that the pH value of the melt is 10-14 (take a small amount of melt test sample and cool it and dissolve it in water to measure the pH value with a glass electrode), keep the melting temperature for 10-20 minutes, and cool to room temperature to obtain a block-shaped environmentally friendly precious metal mineral processing agent .

Embodiment 3

[0026] The weight ratio of yellow blood salt and urea is 1:5, mix yellow blood salt and urea, put it in the reactor, in the process of slowly heating up, add pH regulator sodium hydroxide and sodium bicarbonate, after heating to molten state , so that the pH value of the melt is 12 to 14 (take a small amount of melt test sample and cool and dissolve it in water to measure the pH value), keep the melting temperature for 20-30 minutes, and cool to normal temperature to obtain a block-shaped environmentally friendly precious metal mineral processing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com