Rust-preventive pigment

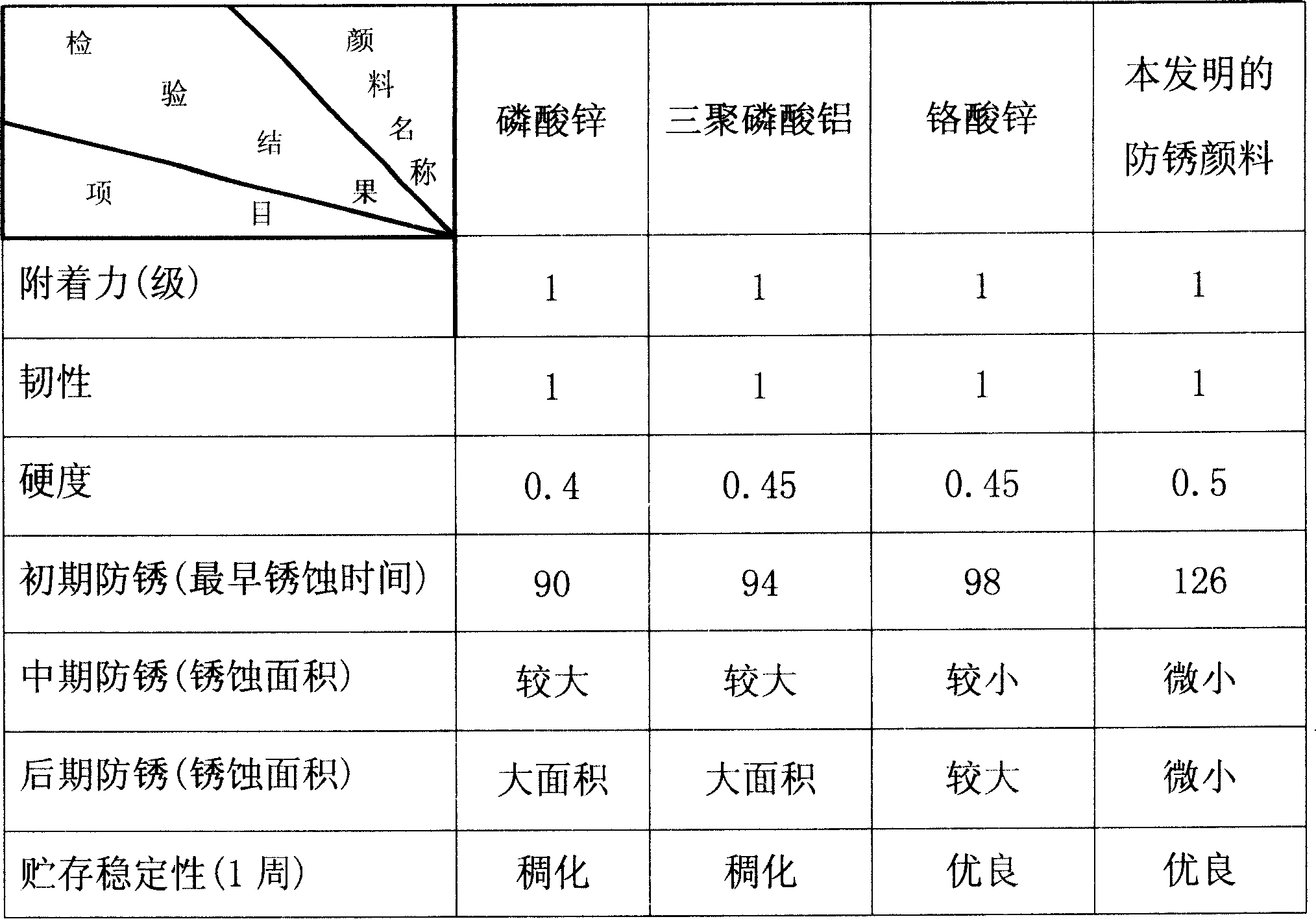

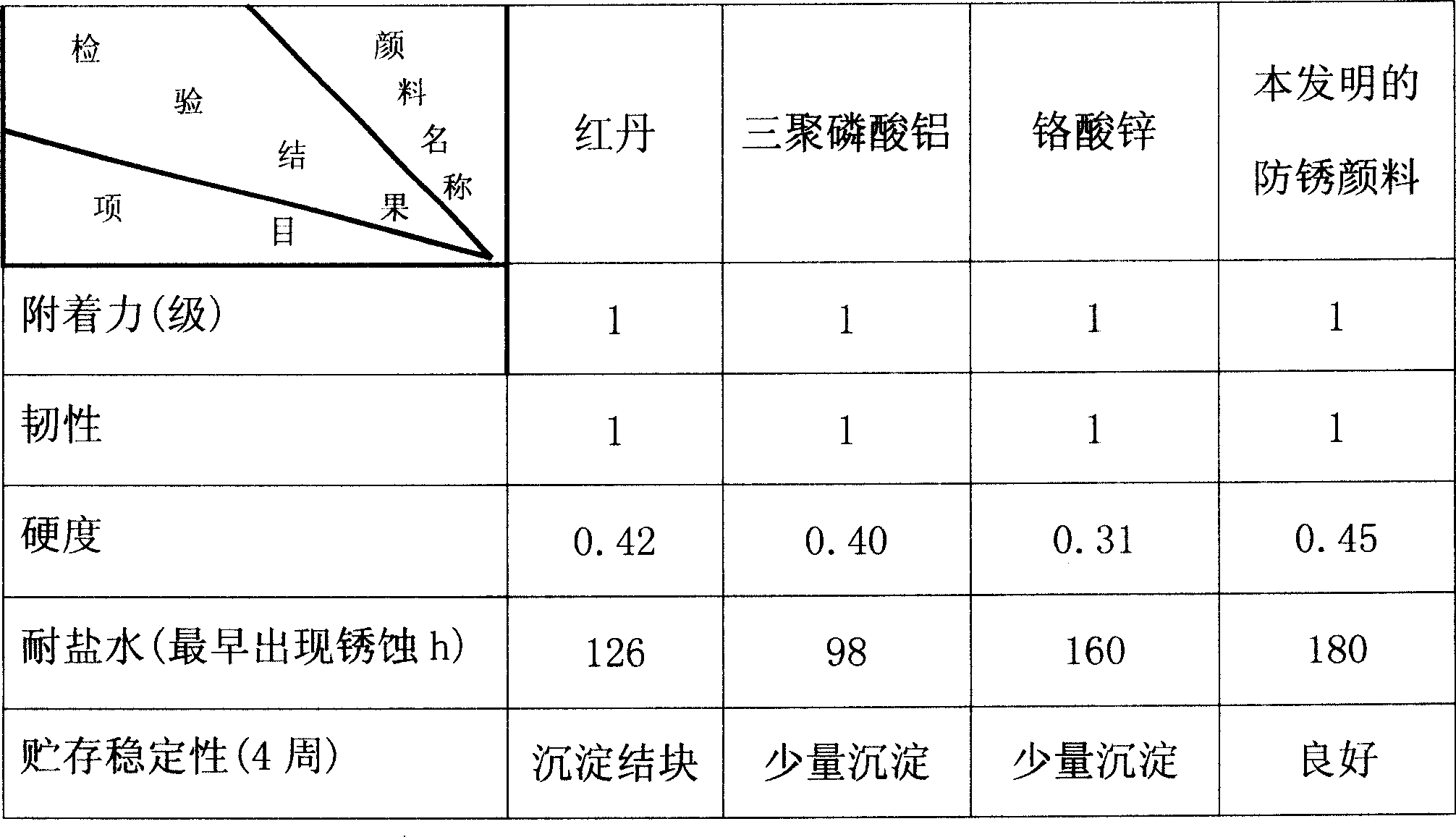

A technology of anti-rust pigment and phytate, which is applied in the field of chemical pigments, can solve problems such as environmental pollution and harm to human health, and achieve the effects of good compatibility, low price and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Slowly add 50% zinc sulfate solution to more than 10% phytic acid aqueous solution, stir while adding, then adjust the pH to 5-6 with caustic alkali or ammonia water, continue stirring for 10 minutes to form zinc phytate, and let it stand for 30 minutes Minutes, solid-liquid separation, then co-deposition polymerization of zinc phytate and mica or mica iron oxide in a weight ratio of 1:1.5, and high-speed homogeneous emulsification to change the aggregate particle size structure to make it reach sub-nanometer (0.2- 2 μm), washed with water, dried, and ground to a particle size of 0.5-4 μm to obtain an antirust pigment containing zinc phytate and mica or micaceous iron oxide.

Embodiment 2

[0015] Slowly add about 30% aluminum sulfate solution to 10% or more phytic acid aqueous solution, stir while adding, then adjust the pH to 3.5-4.0 with caustic soda or ammonia water, continue stirring for 16 minutes to form aluminum phytate, let stand After 35 minutes, carry out solid-liquid separation, then carry out co-deposition polymerization of aluminum phytate and mica or mica iron oxide at a weight ratio of 1:6, and change the aggregate particle size structure through high-speed homogeneous emulsification to make it reach sub-nanometer (0.2 -2 μm), washed with water, dried, and ground to a particle size of 0.5-4 μm to obtain an antirust pigment containing aluminum phytate and mica or micaceous iron oxide.

Embodiment 3

[0017] Slowly add 10-30% ferric chloride solution to more than 10% phytic acid aqueous solution, stir while adding, then adjust PH=5 with caustic alkali or ammonia water, continue stirring for 10 minutes, and generate ferric phytate, static Set aside for 15 minutes, carry out solid-liquid separation, and then co-deposit and polymerize ferric phytate and mica or mica iron oxide at a weight ratio of 1:1, and change the aggregate particle size structure through high-speed homogeneous emulsification to make it reach sub-nanometer ( 0.2-2 μm), washed with water, dried, and ground to a particle size of 0.5-4 μm to obtain an antirust pigment containing ferric phytate and mica or micaceous iron oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com