Modified starch binder used for granulation of organic fertilizer and preparation method thereof

A technology of binder and starch, which is applied to the field of modified starch binder for organic fertilizer granulation and its preparation, can solve the problems of high cost, environmental pollution, complicated production process of binding materials, etc., and achieves low cost and environmental protection. Friendly, good granulation and bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

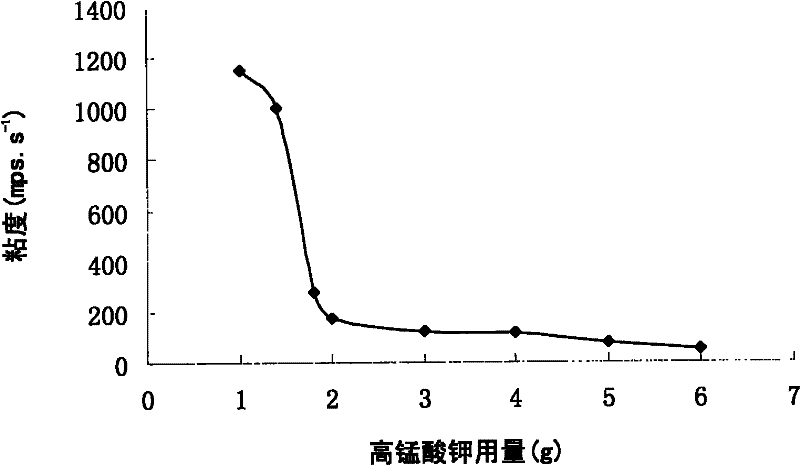

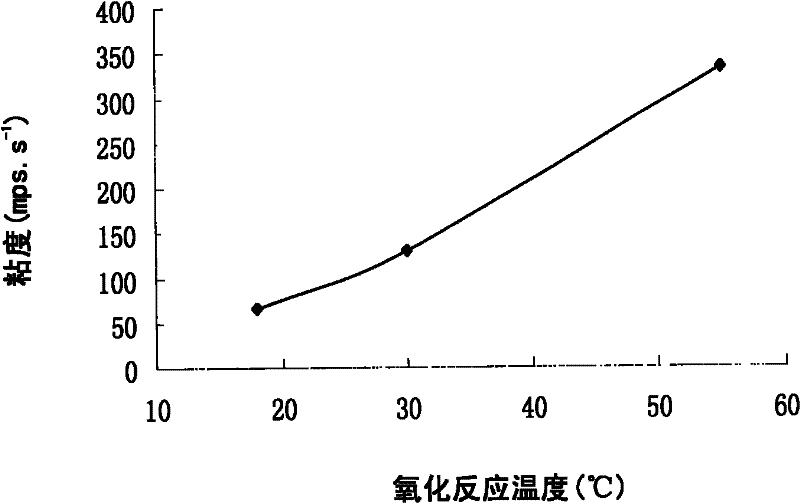

[0022] Embodiment 1, the preparation of modified starch binder

[0023] 1) Swell 100g of cornstarch with water for 5min; then add it to 300g of water and stir, place the system in a water bath at 50°C, then add 1.0mL of concentrated sulfuric acid (the pH of the system is 1.0) to the system and stir After adding 1.8g of potassium permanganate and 1.5g of oxalic acid, the oxidation reaction was carried out for 30 minutes, and the oxidation reaction was terminated with 2g of sodium thiosulfate to obtain 400g of oxidized starch.

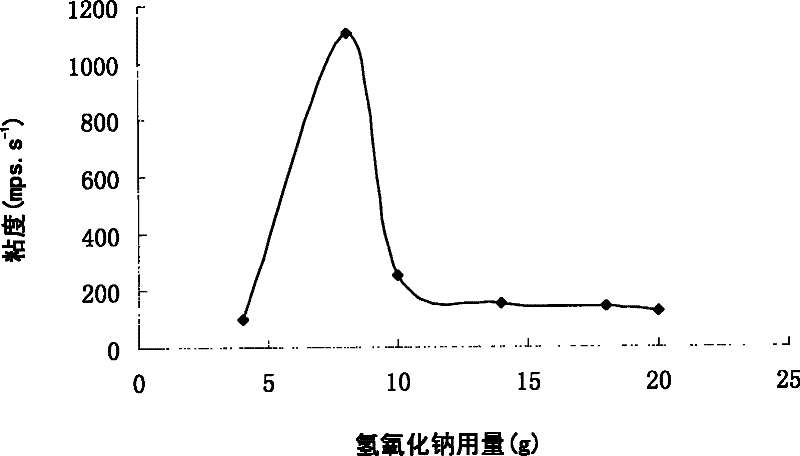

[0024] 2) Add 10g of sodium hydroxide to the above oxidized starch and stir for 6min, then add 1.5g of borax to the system for cross-linking reaction, control the temperature at 40°C, add 0.1g of tributyl phosphate after 15min of reaction, stir evenly Obtain 500g modified starch binder.

Embodiment 2

[0025] Embodiment 2, the preparation of modified starch binder

[0026] 1) Swell 200g of wheat starch with water for 5min; then add it to 600g of water and stir, place the system in a water bath at 55°C, then add 2.0mL of concentrated sulfuric acid (the pH of the system is 1.0) to the system and stir After uniformly adding 3g potassium permanganate and 3.5g oxalic acid in sequence, the oxidation reaction was carried out for 30 minutes, and the oxidation reaction was terminated with 3.5g sodium thiosulfate to obtain 700g oxidized starch.

[0027] 2) Add 16g of sodium hydroxide to the above oxidized starch and stir for 8 minutes, then add 2g of borax to the system for cross-linking reaction, control the temperature at 45°C, add 0.3g of tributyl phosphate after 20 minutes of reaction, and stir evenly to obtain 800g modified starch binder.

Embodiment 3

[0028] Embodiment 3, the preparation of modified starch binder

[0029] 1) Swell 1kg of potato starch with water for 10min; then add it to 3kg of water and stir, place the system in a water bath at 60°C, then add 17mL of concentrated sulfuric acid (the pH of the system is 1.0) to the system and stir evenly After adding 20g of potassium permanganate and 20g of oxalic acid in turn, the oxidation reaction was carried out for 45min, and the oxidation reaction was terminated with 20g of sodium thiosulfate to obtain 4kg of oxidized starch.

[0030] 2) Add 100g of potassium hydroxide to the above oxidized starch and stir for 10min, then add 20g of borax to the system for cross-linking reaction, control the temperature at 45°C, add 5g of tributyl phosphate after reacting for 15min, and stir evenly to obtain 5kg Modified starch binder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com