Latex for papermaking, preparation method and coating containing latex for papermaking

A latex and emulsion technology, which is applied in the field of latex for papermaking, preparation and coatings containing the latex for papermaking, can solve the problems of easy powder falling, poor wet strength of paper, etc., to overcome the poor wet strength, excellent performance, and meet the needs of the market and social needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of papermaking latex of the present invention, it comprises the steps:

[0021] (1) Prepare starch slurry.

[0022] Add water and starch to a container equipped with a stirrer to make a starch slurry with a concentration of 20%-40% by mass.

[0023] The starch is selected from at least one of tapioca starch, corn starch, potato starch, wheat starch and waxy corn starch.

[0024] (2) Oxidation of starch slurry.

[0025] Add an oxidizing agent to the starch slurry, the amount of the oxidizing agent is 7%-10% of the starch mass, and oxidize for 2-3 hours to prepare the oxidized starch slurry.

[0026] The oxidizing agent is at least one selected from sodium hypochlorite, hydrogen peroxide and potassium persulfate.

[0027] (3) Modification of starch slurry.

[0028] Adding a hydrophobic modifier to the oxidized starch slurry, adjusting the pH of the oxidized starch slurry to 3.5-9.5, performing hydrophobic modification for 3-7 hours, and obtainin...

Embodiment 1

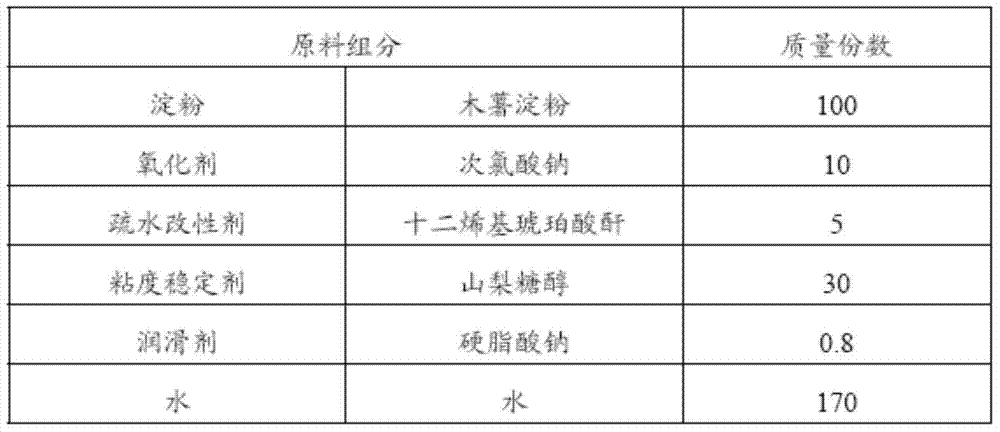

[0047] The formula of the latex of embodiment 1 is specifically referred to table 1:

[0048] Table 1 Latex formula for papermaking

[0049]

[0050] The preparation method of the latex of embodiment 1 comprises the following steps: add starch and water by the number of parts, make 37% starch slurry, stir evenly. Add sodium hypochlorite and oxidize at room temperature for 2h. Then add dodecenyl succinic anhydride, adjust the pH to 8.5-9.0, stir and react at room temperature for 5 hours, then add sorbitol and sodium stearate, and gelatinize at 95°C for 30 minutes to obtain a paper-making product with water resistance latex.

[0051] The formula of the coating containing the latex for papermaking in Example 1: the coating contains 95 parts of calcium carbonate, 5 parts of china clay, 0.03 part of sodium polyacrylate, 0.4 part of hydroxyethyl cellulose, 0.01 part of organosilicon defoamer, hydrogen 0.5 part of sodium oxide, 0.5 part of triazinyl aminostilbenes, 0.01 part of...

Embodiment 2

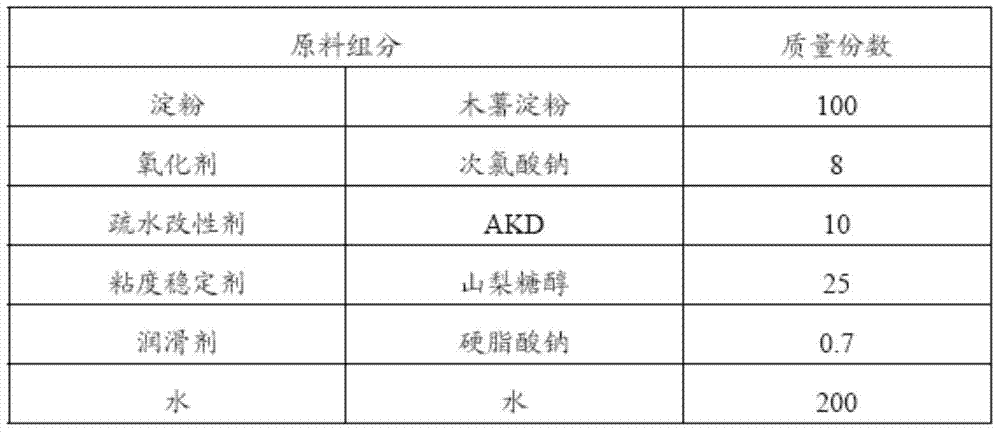

[0054] The formula of the latex of embodiment 2 is specifically referred to table 2:

[0055] Table 2 Latex formula for papermaking

[0056]

[0057] The preparation method of the latex of embodiment 2 comprises the steps: add tapioca starch and water by fraction, make the starch slurry of 33.3%, stir evenly. Add sodium hypochlorite and oxidize at room temperature for 3h. Then add AKD, adjust the pH to 8.5-9.5, stir and react at room temperature for 3 hours, then add sorbitol and sodium stearate, and gelatinize at 95°C for 30 minutes to prepare latex for papermaking with water resistance.

[0058] The formulation of the coating containing the latex for papermaking in Example 2: refer to the formulation in Example 1, except that the latex for papermaking prepared in Example 2 is added, and other parameters are the same.

[0059] Add water and stir the above coating components, adjust the solid content of the coating to 70%, and produce coated paper under the doctor blade c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com