Low-viscosity starch glue for preparing starch capsules as well as preparation method and application of low-viscosity starch glue

A technology of starch capsules and starch glue, which is applied in the directions of capsule delivery, medical preparations with inactive ingredients, pharmaceutical formulations, etc., can solve the problems such as the inability to meet the standard requirements of hollow capsules, and achieves reduction of equipment investment costs, simple and feasible process, and improvement of The effect of structure and properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

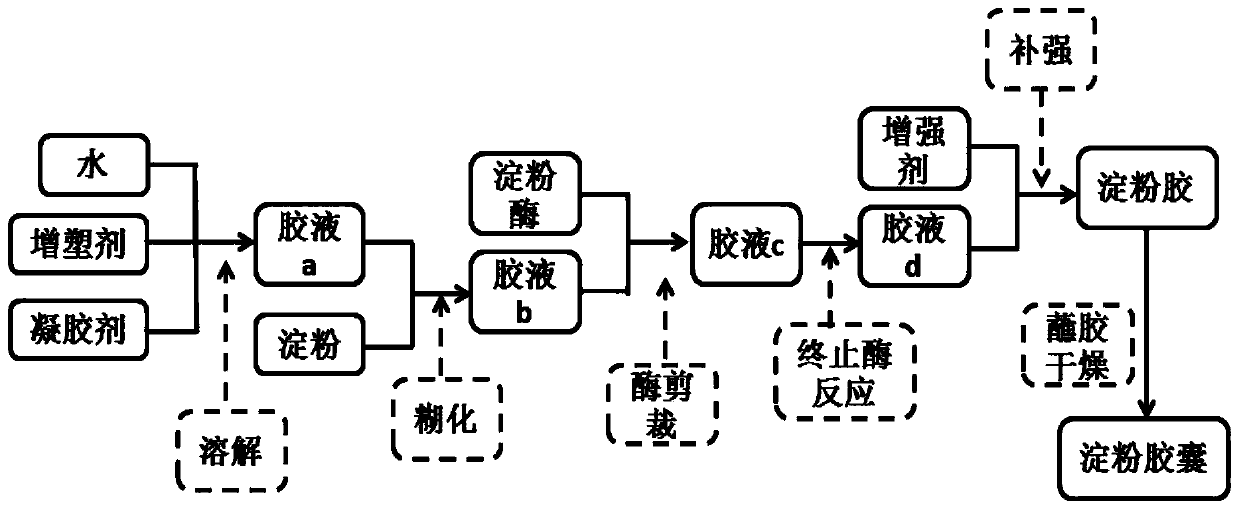

Method used

Image

Examples

Embodiment 1

[0058] In a 180L reactor, add 100L distilled water, 1.2 parts of sorbitol, and 0.8 parts of carrageenan, heat it to 40°C and stir for 30 minutes to completely dissolve it, then raise the temperature to 70°C (at this temperature, the carrageenan dissolves quickly and fully) , stir mechanically at this temperature for 30 minutes to fully dissolve, add 8 parts of cornstarch, stir at a speed of 400r / min, slowly raise the temperature to 90°C until stirring for 80 minutes, lower the temperature to 65°C, and weigh 0.06 parts of α-amylase Add it into the glue, keep the temperature and continue to stir at 400r / min for 45 minutes, quickly add 460mL1mol / L sodium hydroxide, and increase the temperature to 85°C (experiments found that the air bubbles are more clean at high temperatures), Stir for 10 minutes to inactivate the enzyme, then quickly add 460uL of 1mol / L dilute hydrochloric acid to neutralize NaOH, add 0.2 parts of hydroxypropyl cellulose, stir until uniform, lower the temperatur...

Embodiment 2

[0063] In a 180L reaction kettle, add 100L distilled water, 1.2 parts of sorbitol, 0.6 gellan gum + 0.2 parts of carrageenan, heat to 50°C, heat and stir for 30 minutes to dissolve completely, raise the temperature to 70°C, and mechanically Stir for 30 minutes to fully dissolve, add 10 parts of amylose, stir at a speed of 400r / min, slowly raise the temperature to 100°C until stirring for 80 minutes, then lower the temperature to 65°C, weigh 0.06 parts of α-amylase and add it to the glue During the process, keep the temperature and continue to stir at 400r / min for 45min, quickly add 460mL of 1mol / L sodium hydroxide, and increase the temperature to 85°C (experiments have found that the air bubbles are discharged more cleanly at high temperatures), and stir for 10min to make the enzyme Inactivate, then quickly add 460mL of 1mol / L dilute hydrochloric acid to neutralize NaOH, add 0.2 parts of hydroxypropyl cellulose, stir until uniform, reduce the temperature of the glue to 70°C and...

Embodiment 3

[0067] In a 180L reaction kettle, add 100L distilled water, 1.8 parts of glycerin, and 1 part of carrageenan, heat it to 60°C and stir for 30 minutes to completely dissolve it, raise the temperature to 70°C, and mechanically stir for 30 minutes at this temperature to fully dissolve, add 8 parts of amylose, stirred at a speed of 400r / min, slowly raised the temperature to 100°C until stirred for 80 minutes, lowered the temperature to 65°C, weighed 0.06 parts of α-amylase and added it to the glue, kept the temperature and Continue to stir for 45 minutes at 400r / min, quickly add 460mL1mol / L sodium hydroxide, and at the same time raise the temperature to 85°C (experiments have found that the air bubbles are discharged more cleanly at high temperatures), stir for 10min to inactivate the enzyme, and then quickly add 460mL1mol / L dilute hydrochloric acid to neutralize NaOH, add 0.2 parts of hydroxypropyl cellulose, stir until uniform, lower the temperature of the glue solution to 70°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com