Process for preparing neosorb and coproducing fructose-glucose syrup

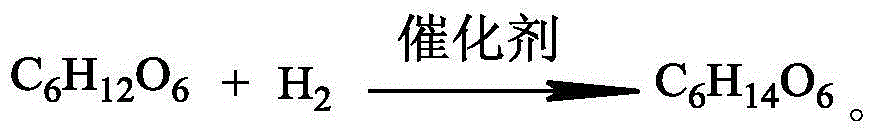

A production process, high fructose syrup technology, applied in the field of starch deep processing, can solve the problem of low sorbitol yield and achieve the effect of no waste of resources and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

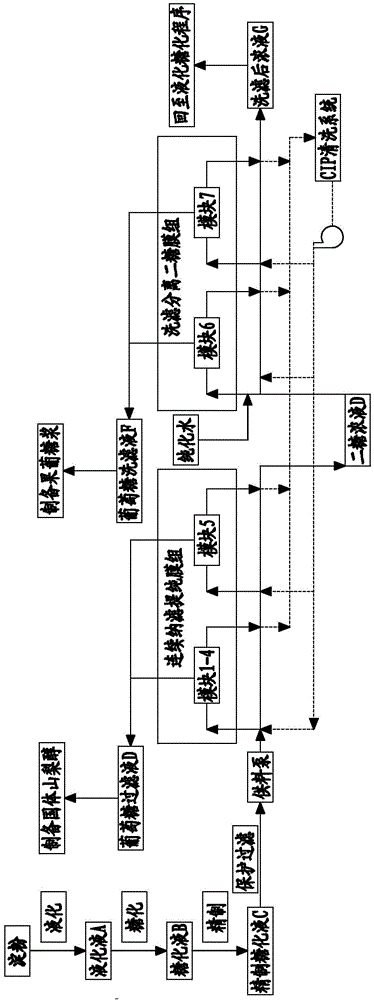

Image

Examples

Embodiment 1

[0050] A kind of production technology of present embodiment prepares solid sorbitol and co-produces fructose syrup, comprises the following steps:

[0051] (1) The starch is prepared into starch milk of 20 degrees Baume (°Be'), and the concentration of Na is 10% by mass percent. 2 CO 3 The solution adjusts the pH value of the starch milk to 5.7-6.0. Calculated based on the dry matter of the starch milk, add 400g / t of high-temperature-resistant a-amylase (Novoxiry high-temperature-resistant a-amylase), and liquefy at 108°C. A liquefied liquid (A) is obtained.

[0052] (2) Use 30% hydrochloric acid to adjust the pH value of the liquefaction solution to 4.0-4.4, then add 450g / t compound enzyme preparation (purchased from Novozymes, trade name: Dextrozyme DX), and saccharify at 60°C for 48h to obtain A saccharified liquid (B) with a glucose content of 95.5%.

[0053] (3) First use a vacuum drum filter to filter the saccharification solution to remove protein, then add 0.2% act...

Embodiment 2

[0070] A kind of production technology of present embodiment prepares solid sorbitol and co-produces fructose syrup, comprises the following steps:

[0071] (1) The starch is prepared into starch milk of 18 degrees Baume (°Be'), and the concentration of 10% Na with a mass percent concentration 2 CO 3 The solution adjusts the pH value of the starch milk to 5.7-6.0. Calculated based on the dry matter of the starch milk, add 400g / t of high-temperature-resistant a-amylase (Novoxiry high-temperature-resistant a-amylase), and liquefy at 108°C. A liquefied liquid (A) is obtained.

[0072] (2) Use 30% hydrochloric acid to adjust the pH value of the liquefaction solution to 4.0-4.4, then add 450g / t compound enzyme preparation (purchased from Novozymes, trade name: Dextrozyme DX), and saccharify at 60°C for 48h to obtain A saccharified liquid (B) with a glucose content of 95.5%.

[0073] (3) First filter the saccharification solution with a nanofiltration membrane to remove protein, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com